Low-nitrogen combustion stokerfeed boiler with two-stage smoke recirculation function

A technology of flue gas recirculation and low-nitrogen combustion, which is applied in chain furnaces and low-nitrogen combustion chain furnaces. It can solve the problems of low efficiency and high emission of chain furnaces, reduce NOx generation, delay combustion process, and reduce NOx emissions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

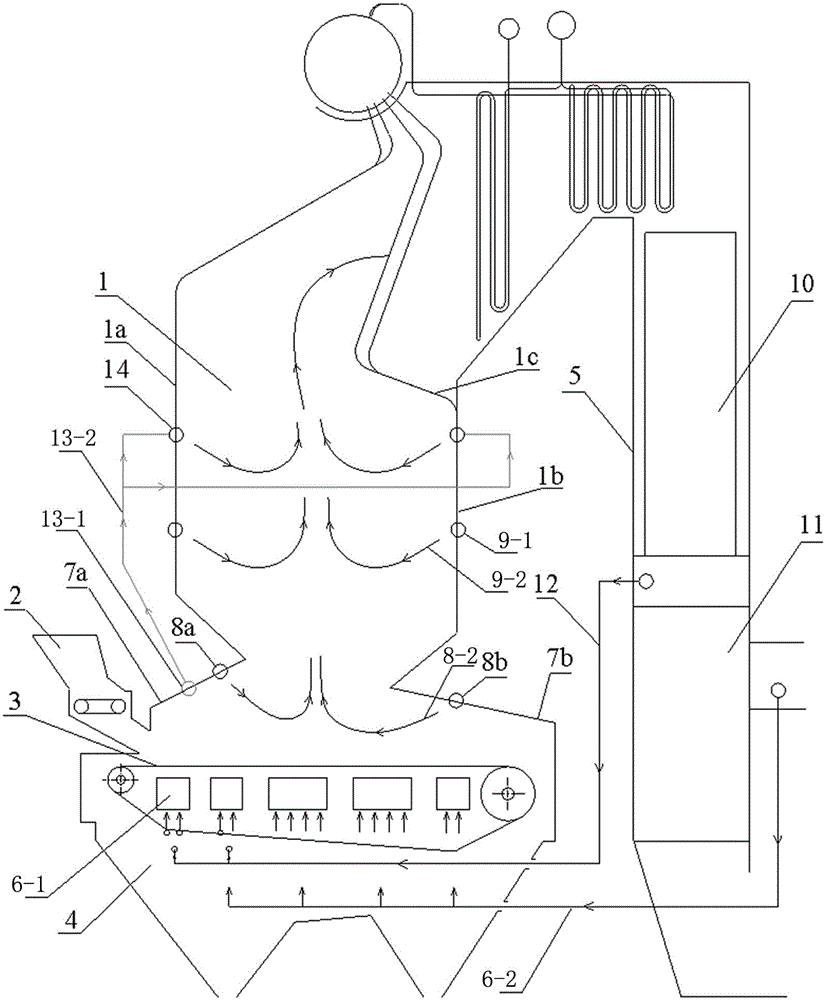

[0016] Such as figure 1As shown, the low-nitrogen combustion chain furnace with two-stage flue gas recirculation of the present invention is composed of a furnace 1, a coal feeder 2, a chain grate 3, a slag hopper 4 and a tail flue 5; The furnace 1 is divided into upper and lower parts by the front furnace arch 7a and the rear furnace arch 7b, and the upper part of the furnace 1 includes a front wall 1a, a rear wall 1b and a flame corner 1c; An economizer 10 and an air preheater 11 are arranged from top to bottom; a plurality of primary air chambers 6-1 are arranged in the space area wrapped by the chain grate 3, and the plurality of primary air chambers 6-1 are arranged along the The traveling direction of the chain grate 3 is arranged in the shape of "one", and the outlets of the plurality of primary air chambers 6-1 communicate with the chain grate 3 to supply the prima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com