Water-cooled grate combustor

A water-cooled grate and burner technology, applied in the direction of combustion method, combustion equipment, solid fuel combustion, etc., can solve the problems of poor adaptability of coal types, high fuel cost, easy damage to the grate temperature, etc., and achieve the improvement of secondary sufficient Combustion, high fuel utilization rate, and the effect of preventing fuel leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

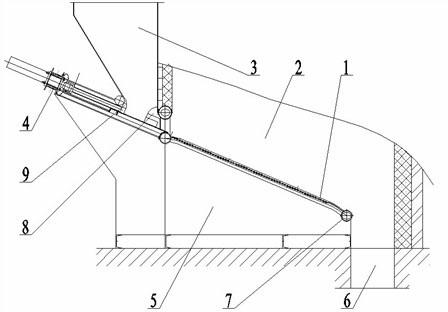

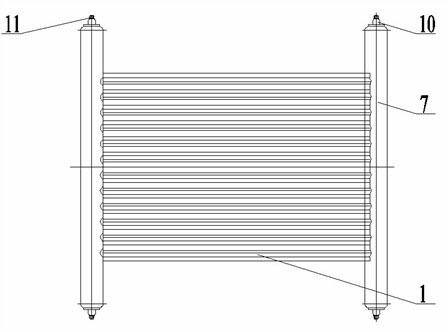

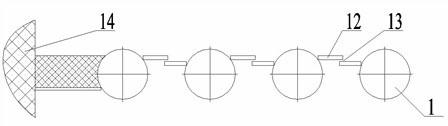

[0019] Such as Figure 1~3 As shown, 1 in the figure is the fixed water-cooled grate, 3 is the hopper at the front of the combustion chamber, 4 is the feeding mechanism in front of the hopper, 5 is the fixed air chamber under the fixed water-cooled grate, and 2 is the upper part of the grate. Combustion chamber, 6 is the ash pit at the front and lower end of the grate; the fixed water-cooled grate 1 is inclined downward by 1 to 30 degrees along the moving direction of the fuel, and the arrangement direction of the fixed water-cooled grate tubes is consistent with the moving direction of the fuel. The upper and lower ends of the water-cooled grate pipe are provided with a water collection box 7 which is vertically connected to it and has a water inlet 10 and a water outlet 11. Between two adjacent fixed water-cooled grate pipes, left and right lap joints, The anti-leakage limiting flaps 12 of planar structure leave air inlet passages 13 on two adjacent limiting flaps. The bott...

example 2

[0024] Depend on Figure 4~5 As shown, it is only a partial structural improvement on the fixed water-cooled grate, and its specific content is: between two adjacent fixed water-cooled grate tubes, an arc-shaped leak-proof limit block 15 overlapping the front and rear is evenly fixed, Leave the air inlet channel 17 (such as Figure 5 Shown), the limit block is an arc structure. Other structures and working process are identical with example 1, so outline it.

[0025] in addition, Figure 4 16 in the hearth is the inner wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com