Staggered forward-push household garbage incineration fire grate structure

A domestic waste incineration and staggered technology, which is applied in the direction of incinerators, inclined grates, grates, etc., can solve the problems of affecting the efficiency of waste incineration and slow waste advancement of fixed beams, so as to achieve good loosening effect of waste and prolong maintenance period , The effect of improving the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

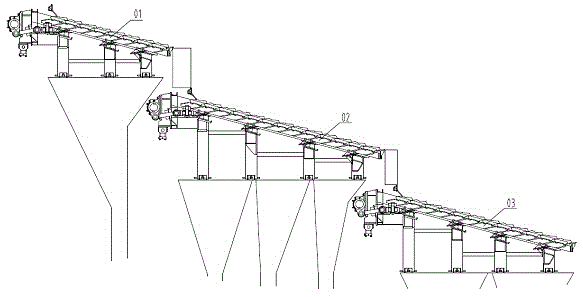

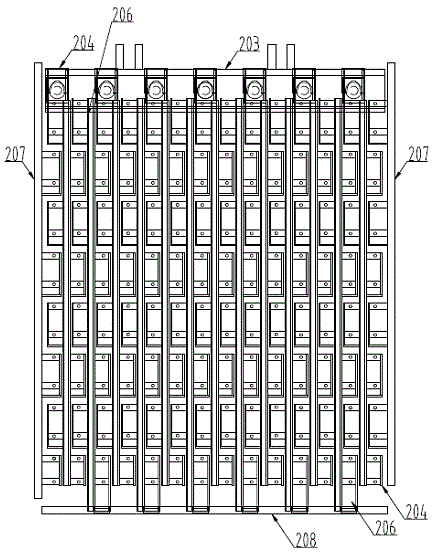

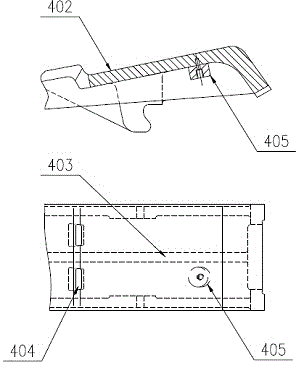

[0020] Such as figure 1 As shown, the staggered forward push grate is divided into three sections, which are the drying section 01, the burning section 02, and the burning section 03. There are drop walls between sections. For the fire grate, a cover fire grate 101 is provided at the front of each section, a sliding fire grate 102 and a fixed fire grate 103 are alternately arranged at intervals, and a blanking fire grate 104 is provided at the end. Each section of the grate has an independent drive system, taking the drying section 01 as an example, such as figure 2 As shown, the hydraulic cylinder 201 at the front of the grate drives the push rod 202 to reciprocate along the garbage conveying direction to drive the driving beam 203 to move, and the driving beam 203 drives the sliding grate beam 204, and a support seat 205 is arranged under the sliding grate beam 204 , the angle between the upper surface of the support seat 205 and the horizontal plane is a forward elevatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com