Biomass direct-fired boiler

A biomass and boiler technology, applied in steam boilers, combustion product treatment, grates, etc., can solve problems such as fire, waste of resources, waste of resources, etc., to avoid drastic changes, reduce initial smoke concentration, and reduce equipment The effect of operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

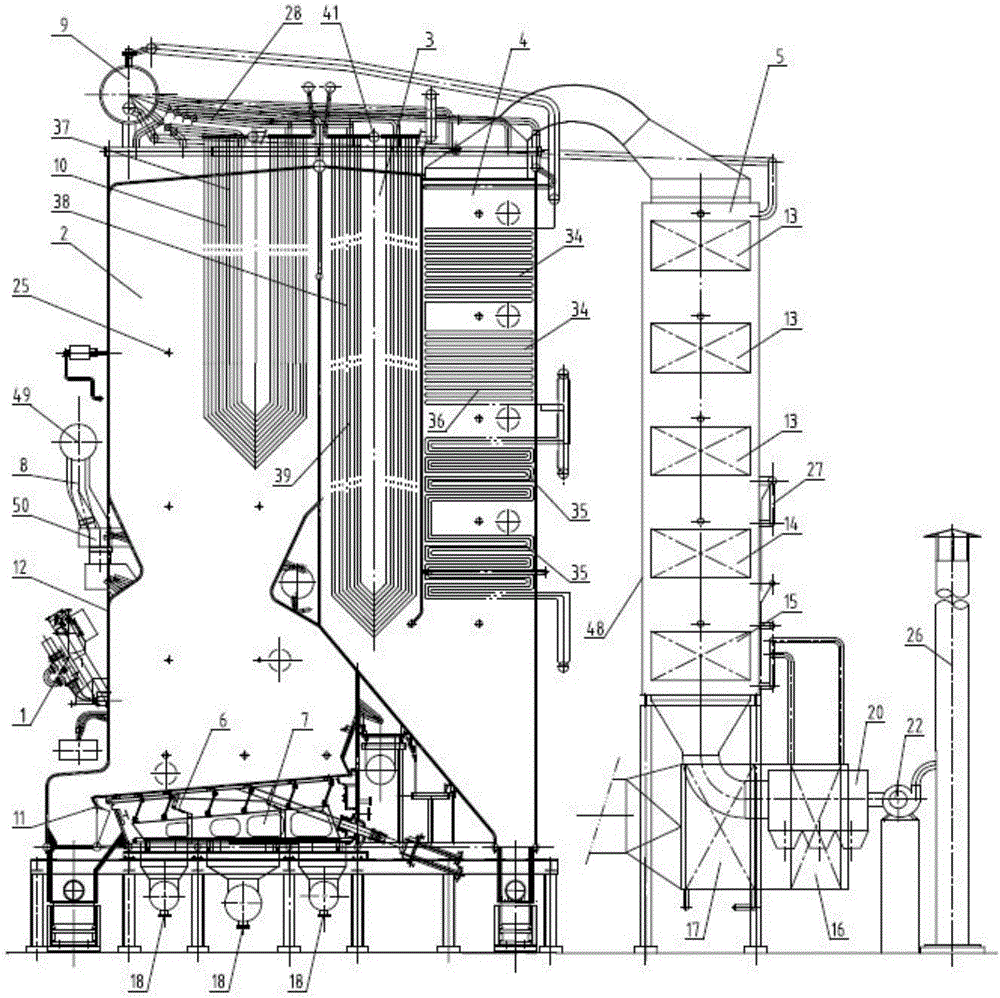

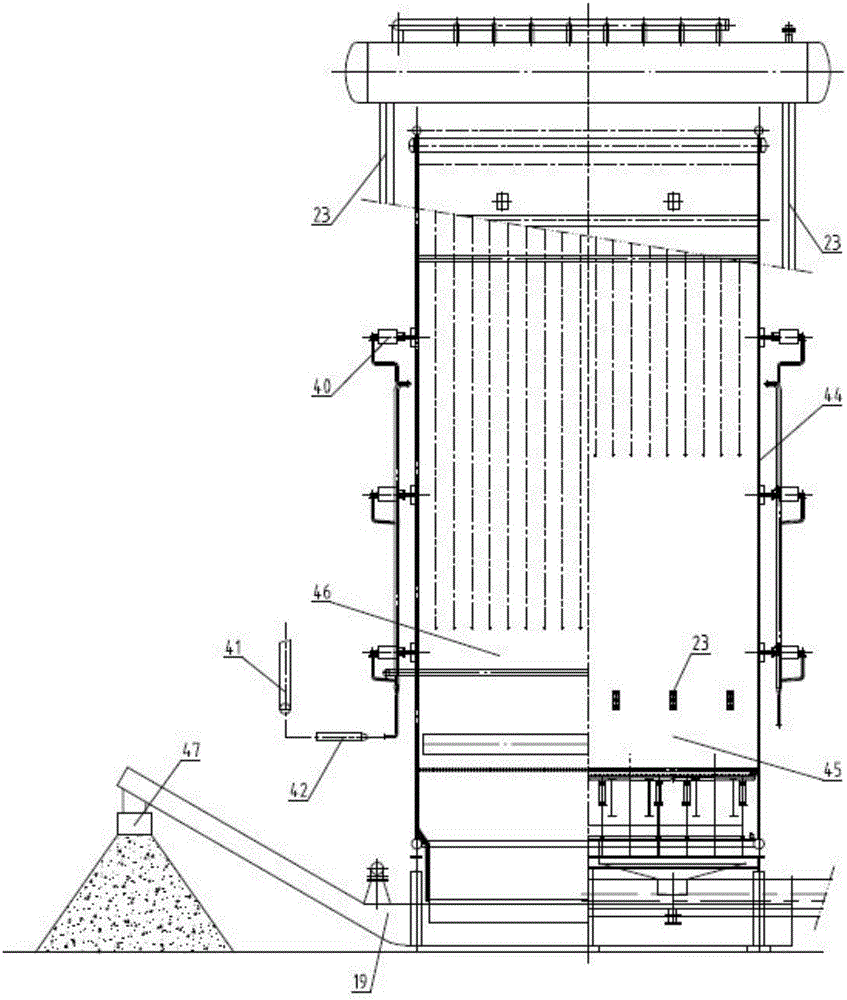

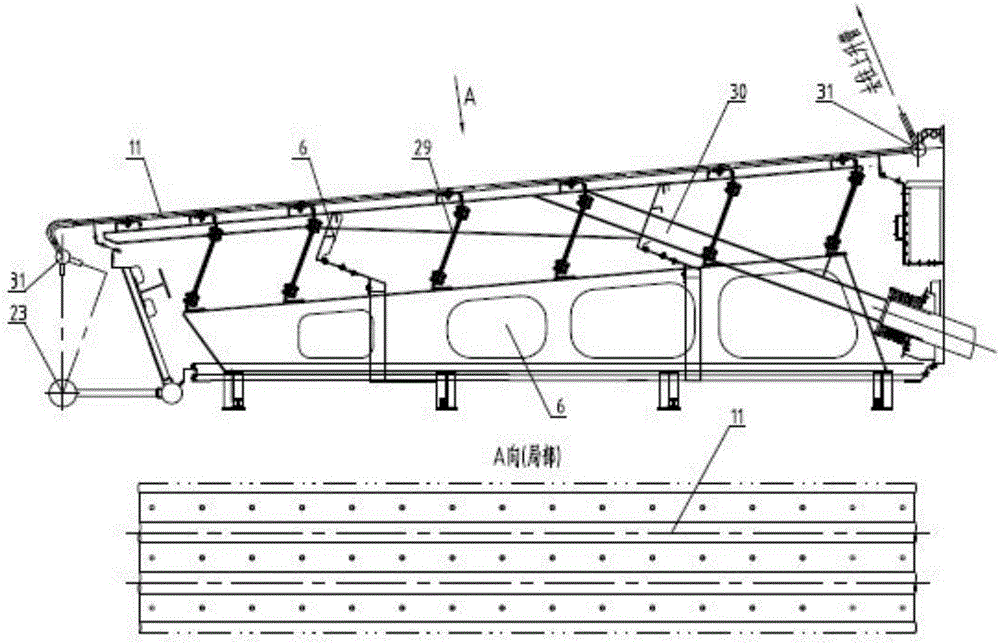

[0037] The accompanying drawing discloses a non-restrictive schematic structural view of a preferred embodiment of the present invention, and the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0038] According to a preferred embodiment of the biomass direct-fired boiler of the present invention, the biomass direct-fired boiler includes: a boiler body 44, which is provided with a combustion chamber 45 composed of a membrane water wall and a multi-return flue 46, The bottom of the combustion chamber 45 is provided with a water-cooled vibrating fire grate 6, and the multi-return flue 46 is provided with a steam superheater 10; the feeding system 1 communicates with the front wall of the boiler body 44 to input biomass fuel into the combustion chamber 45; discharge system 47, which is arranged at the bottom of the multi-return flue 46 and the water-cooled vibrating grate 6, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com