Pick push type reciprocating fire grate device correspondingly driven by double oil cylinders from two sides

A dual-cylinder, reciprocating furnace technology, applied in inclined grate, grate, incinerator, etc., can solve the problems of large grate area, poor waste stirring effect, low incineration efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is further described in conjunction with the accompanying drawings and specific embodiments.

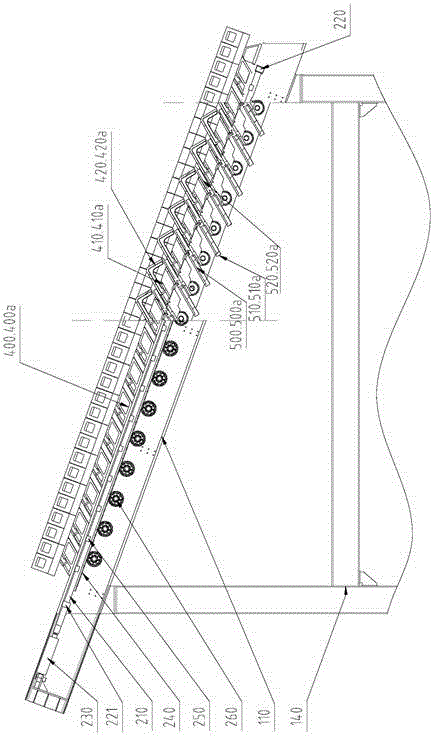

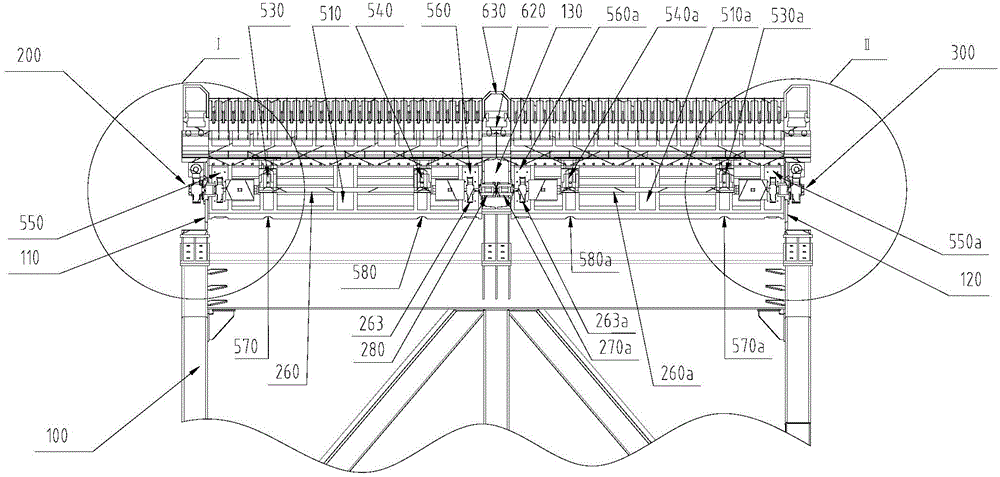

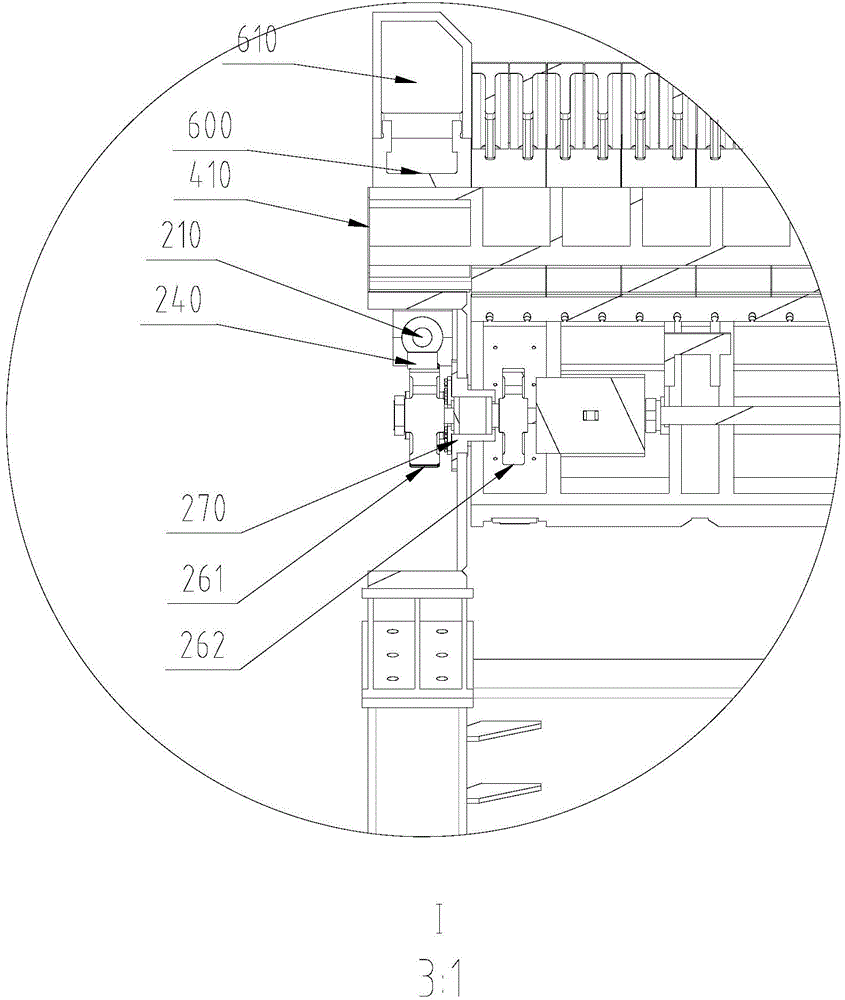

[0036] see Figure 1 to Figure 4 , the pick-and-push reciprocating furnace blower device driven correspondingly on both sides of the double oil cylinder shown in the figure includes a plurality of supports 140 and a certain furnace blower shelf 100, and the fixed furnace blower shelf 100 is composed of left longitudinal beams 110, The right longitudinal beam 120 and the middle longitudinal beam 130 arranged in the middle between the left longitudinal beam 110 and the right longitudinal beam 120 are formed. Inclined.

[0037] The middle longitudinal beam 130 divides the entire fixed furnace blower frame 100 into left and right regions, the furnace blower frame in the left region is between the left longitudinal beam 110 and the middle longitudinal beam 130, and the right region is between the right longitudinal beam 120 and the middle longitudinal beam 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com