Spare part demand forecast method based on in-service lift estimation

A technology of demand forecasting and life assessment, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of being easily interfered by other factors, occupying enterprise funds, and large error in spare parts demand forecasting, so as to achieve reliable forecasting The effect of improved performance and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

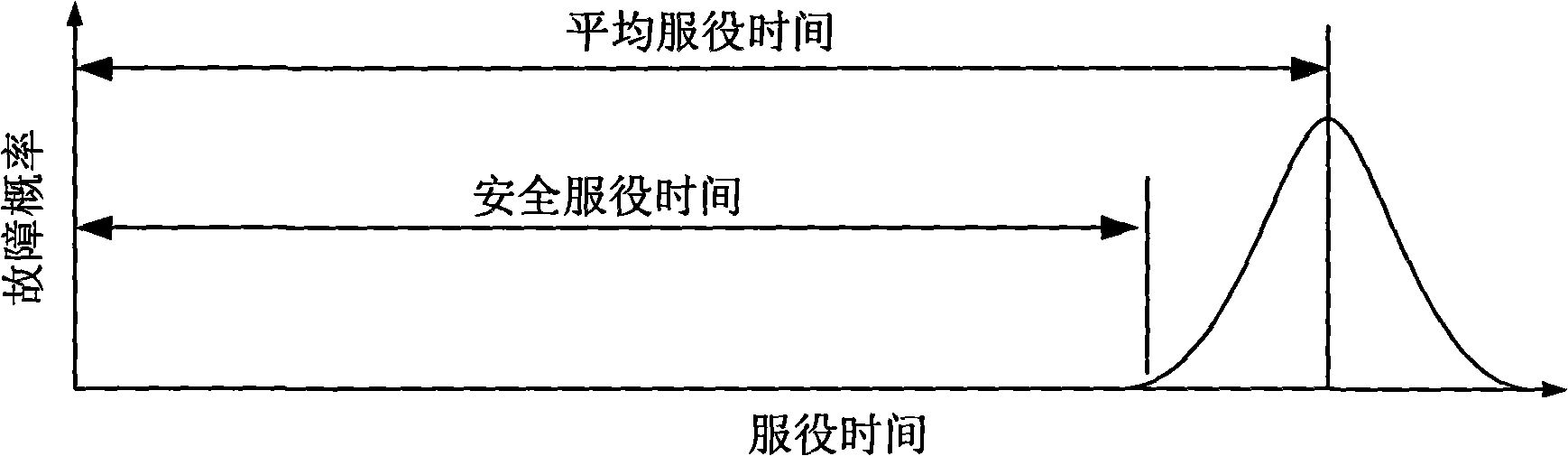

[0026] refer to figure 1 As shown, the horizontal axis represents the service time, and the vertical axis represents the failure probability. According to the central limit theorem, the probability of components failing to be replaced during equipment operation conforms to a normal distribution. In a fixed service position, the probability of a component reaching the average service time is the largest, and the farther away from the average service time, the smaller the probability. In practical applications, a certain time value shorter than the average service time is often used as the safe service time. After the spare parts are in service and reach the safe service time, spare parts need to be prepared in advance for replacement, resulting in the demand for spare parts.

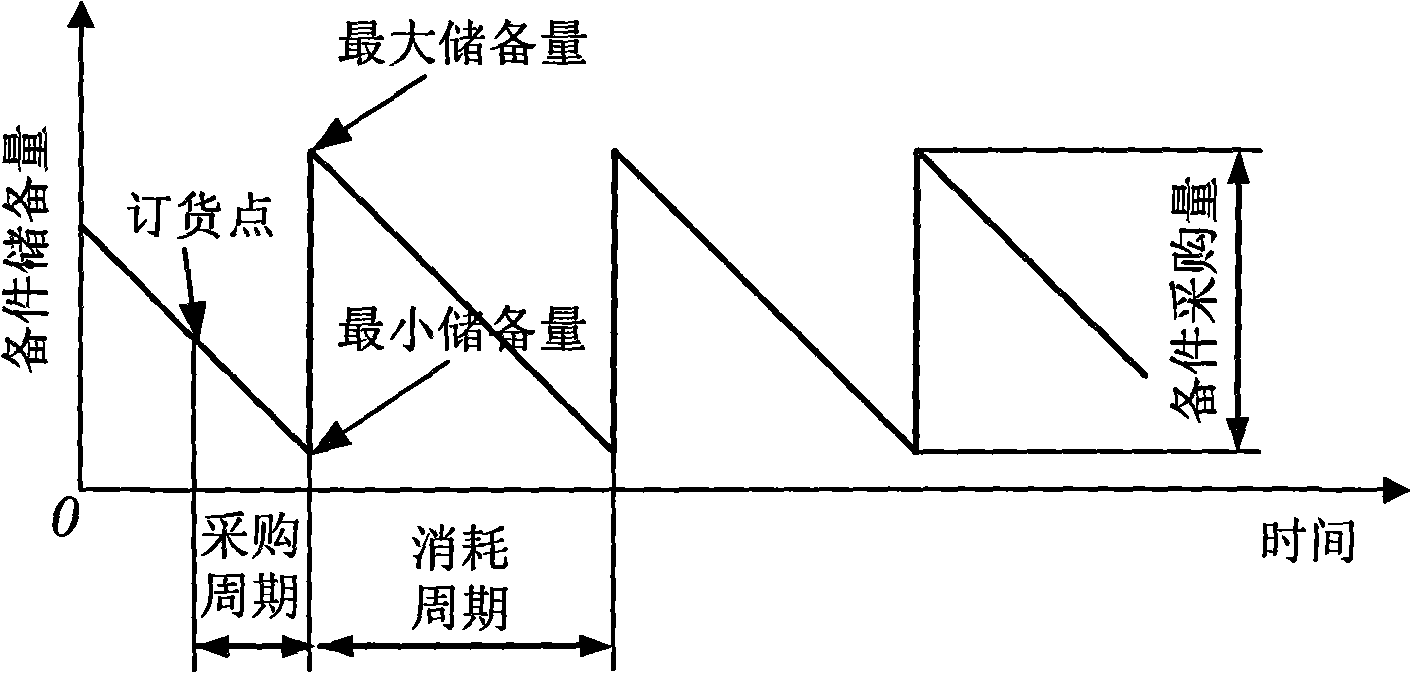

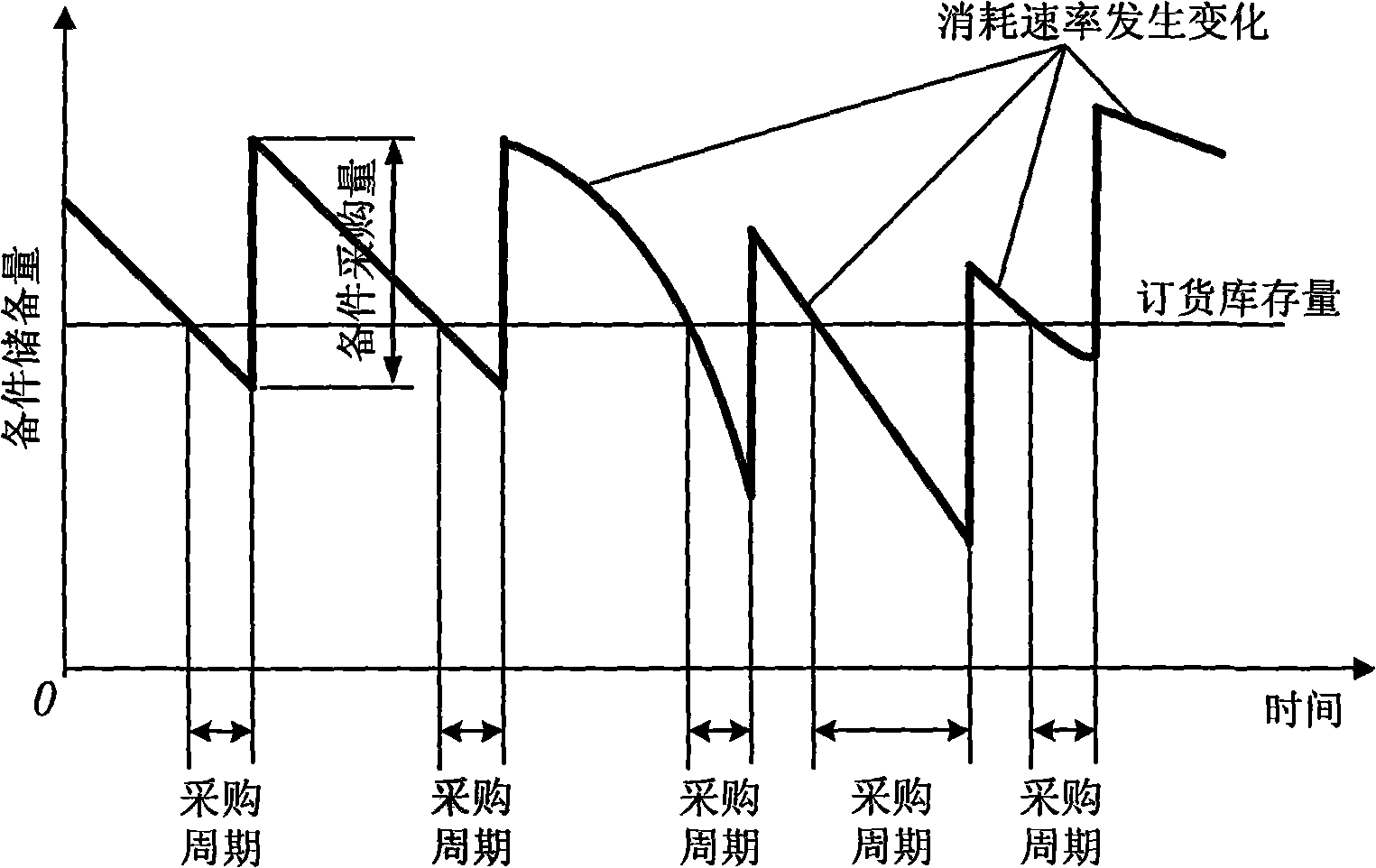

[0027] refer to figure 2 As shown, the horizontal axis represents time, and the vertical axis represents the spare parts reserve. The ideal spare parts reserve changes in a "wave" manner. There is a ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com