Load analysis method for four-wheel six-component road spectrum of finished automobile

An analysis method and vehicle load technology, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve problems that cannot truly reflect the stress of various systems and components of the vehicle, and are not conducive to the quantification of vehicle fatigue analysis results. It can predict and optimize the fatigue durability performance of the vehicle structure, solve the fatigue durability performance of the vehicle structure, and shorten the research and development cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings.

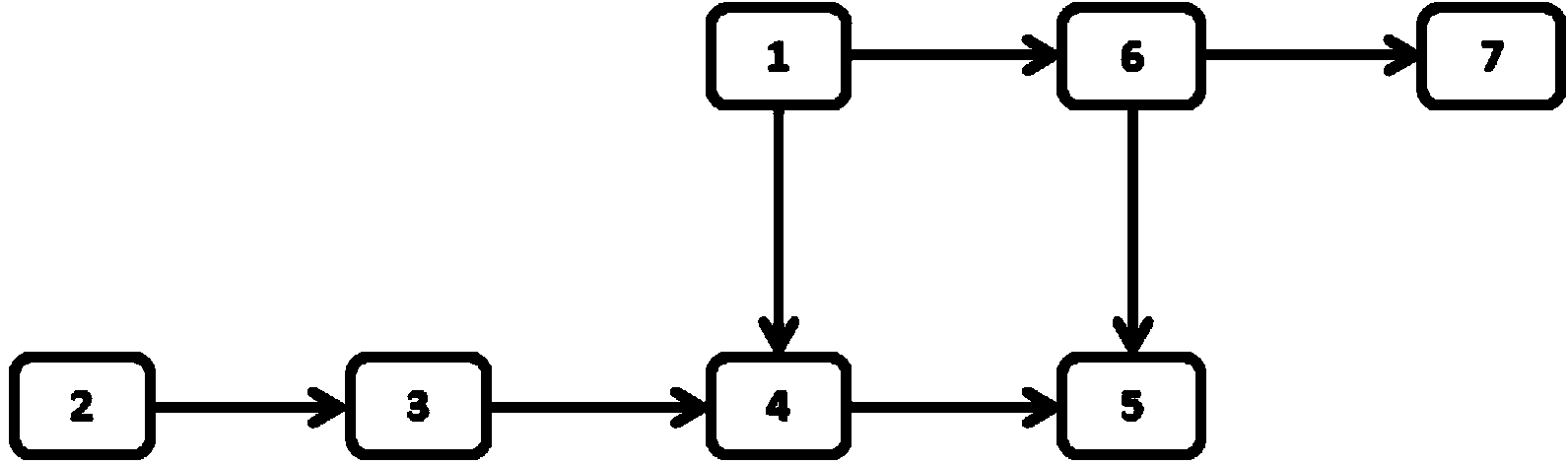

[0038] see figure 1 , the steps of the road spectrum load analysis method for the four-wheel six-component force are as follows:

[0039] 1. Vehicle four-wheel six-component force road spectrum test

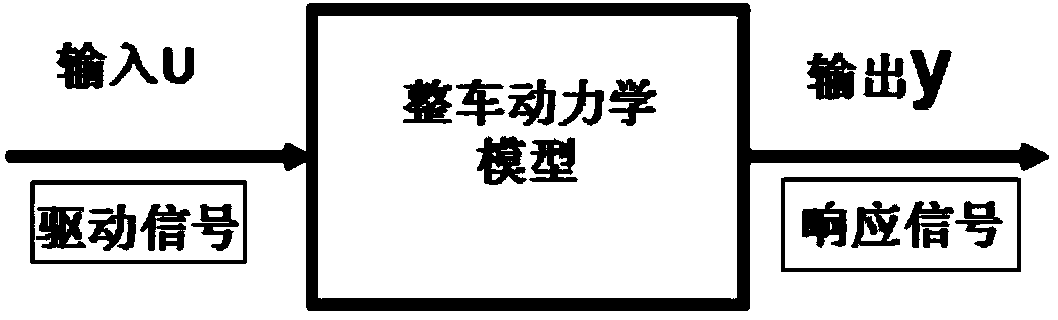

[0040] The four-wheel six-component force road spectrum test of the whole vehicle not only tests the six-component force at the center of the four wheels, but also tests signals such as spring displacement, wheel center acceleration, and shock absorber force.

[0041] 2. Vehicle design data collection

[0042] Obtaining real and effective vehicle design data is a prerequisite for establishing a vehicle dynamics model. Vehicle design data, including vehicle axle and wheel load distribution, design hard points, quality characteristics of chassis parts, chassis bushing stiffness, powertrain quality characteristics and suspension bushing stiffness, spring stiffness, shock ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com