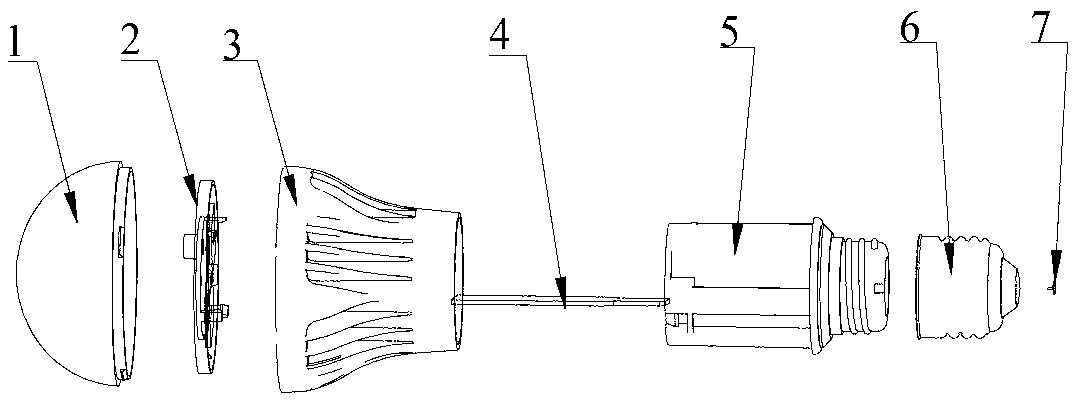

LED bulb lamp assembly and production equipment

A technology for LED bulb lamps and production equipment, which is applied in lighting and heating equipment, lighting devices, components of lighting devices, etc., can solve problems such as the inability of production capacity to meet huge demand, and achieve the effect of improving production efficiency and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

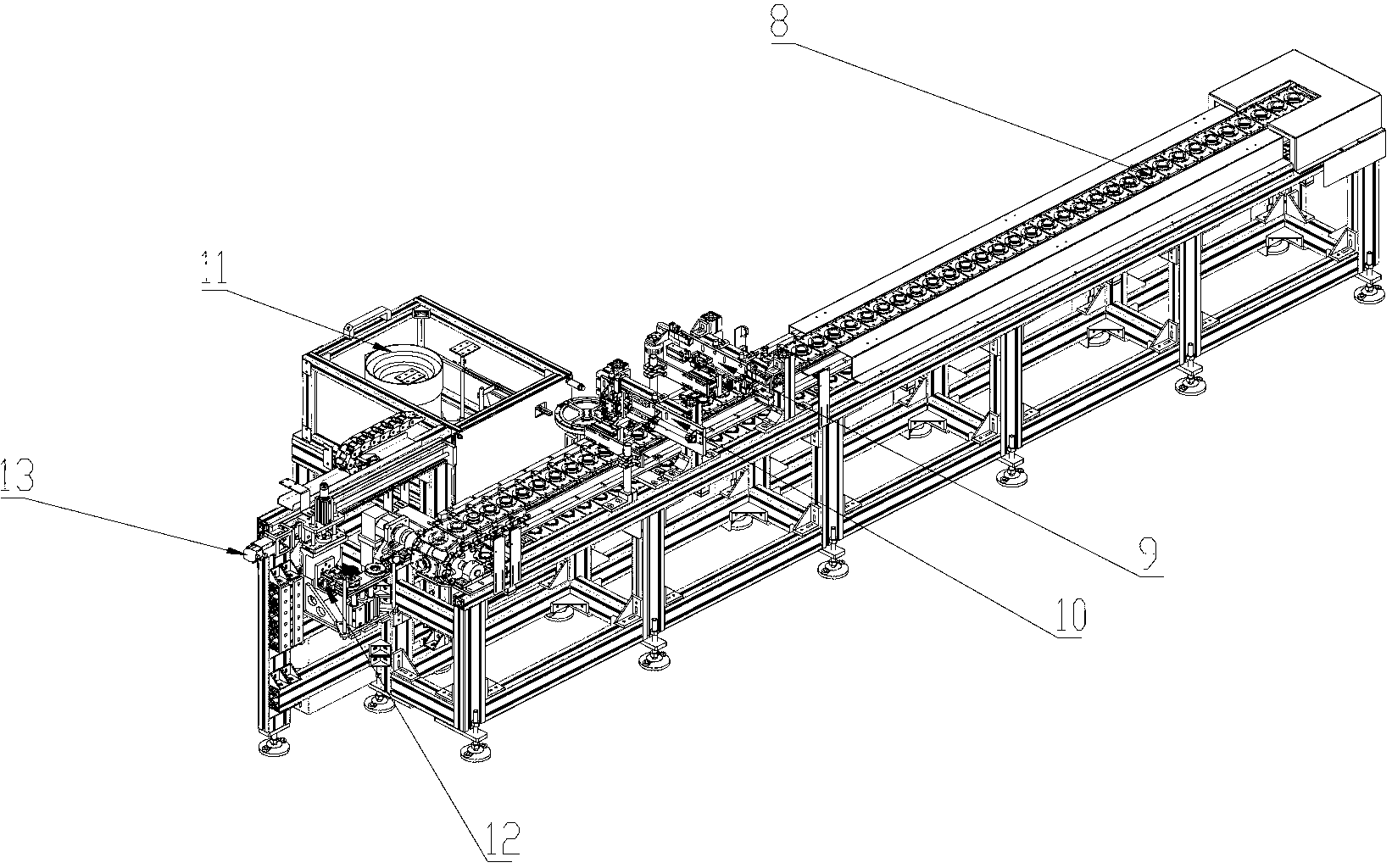

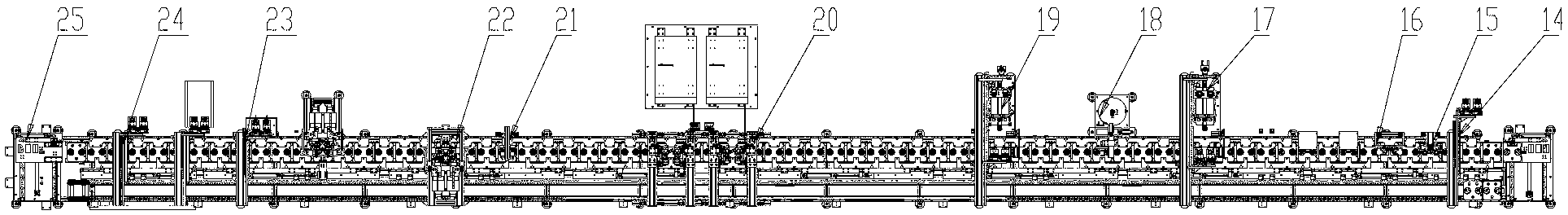

[0030] According to attached figure 2 , attached image 3 , attached Figure 4 , and attached Figure 5 As shown in the structure, a kind of LED bulb lamp assembly and production equipment is manufactured, including a rivet assembly part 33, a light source board assembly part 34, a lampshade assembly part 35, and a lampshade stack feeding mechanism 36, wherein the rivet assembly part 33 has a chain transmission mechanism 8 in sequence , the central wire line management mechanism 9, the rivet loading mechanism 10, the rivet vibrating plate 11, the turning and handling manipulator 12 and the transfer station 13; the light source board assembly part 34 has a CCD imaging mechanism 14, a lamp head circumferential orientation mechanism 15, a line management mechanism 16, Heat sink assembly mechanism 17, locking screw mechanism 18, heat-conducting silicone grease coating mechanism 19, light source board assembly mechanism 20, wire trimming mechanism 21, wire welding mechanism 22, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com