High-precision positioning rotational station

A high-precision, pan-tilt technology, applied in the direction of machine/stand, supporting machine, mechanical equipment, etc., can solve the problems of insufficient rotation, inaccurate positioning, loss of control signals, etc., and achieve the effect of improving measurement accuracy and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

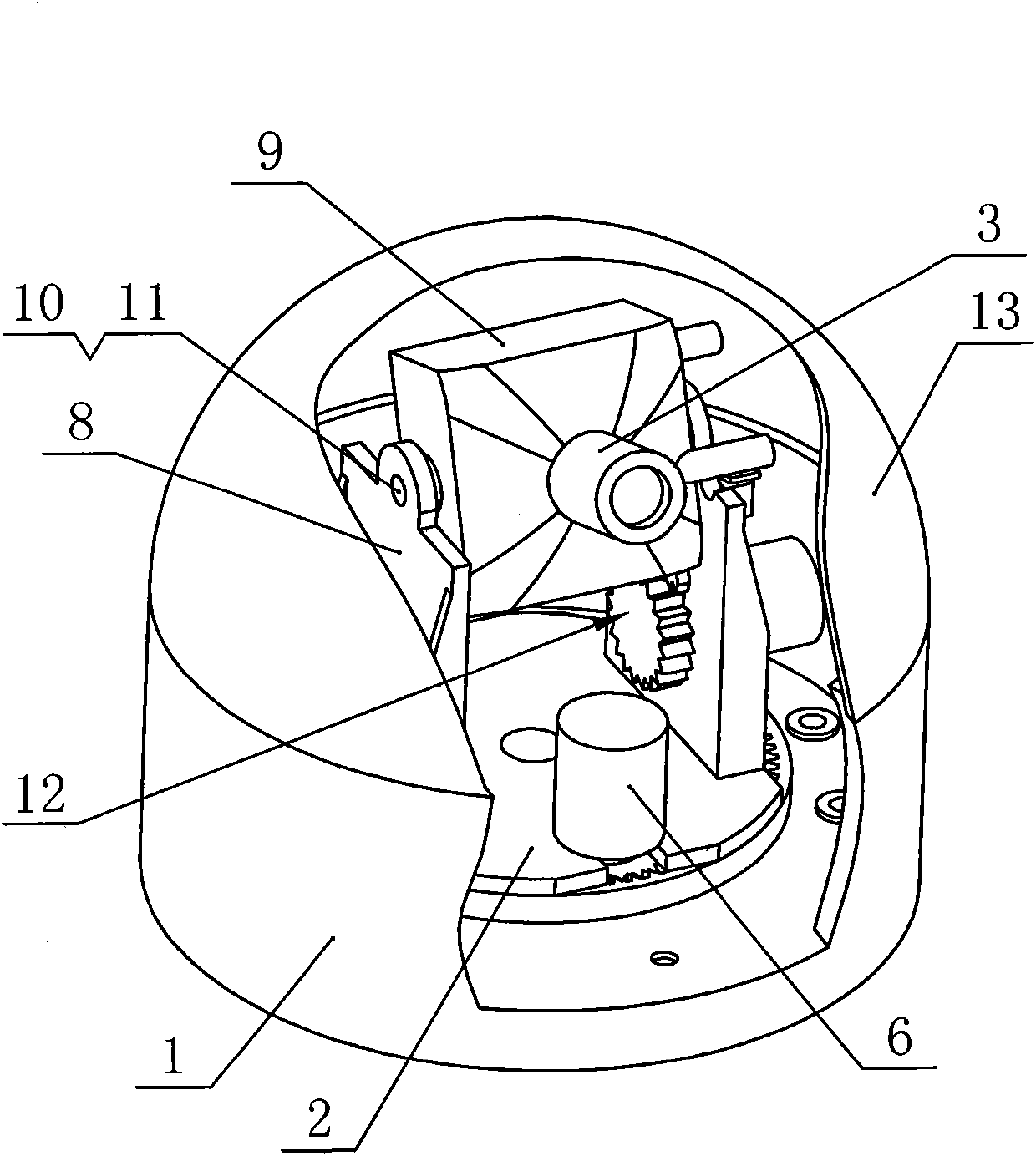

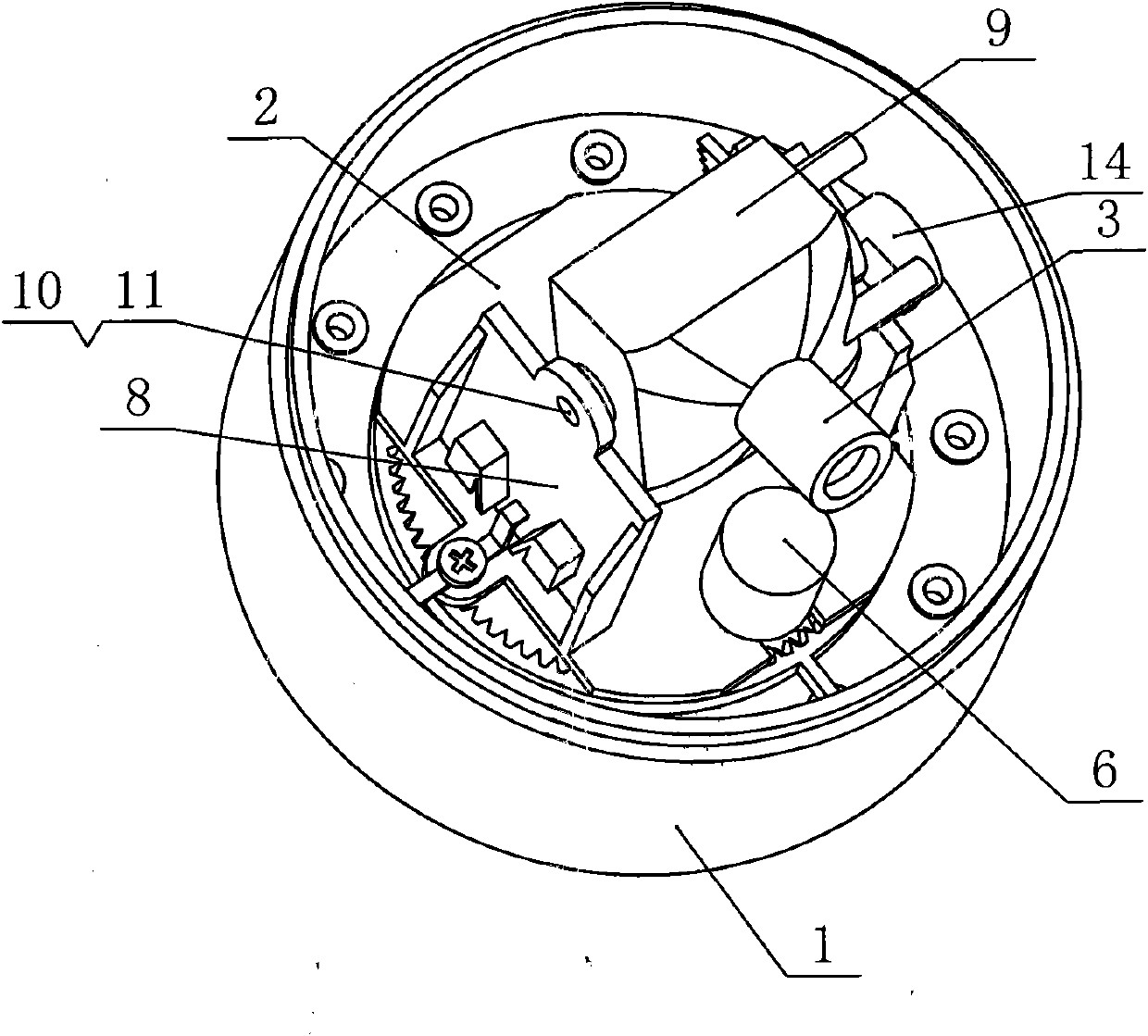

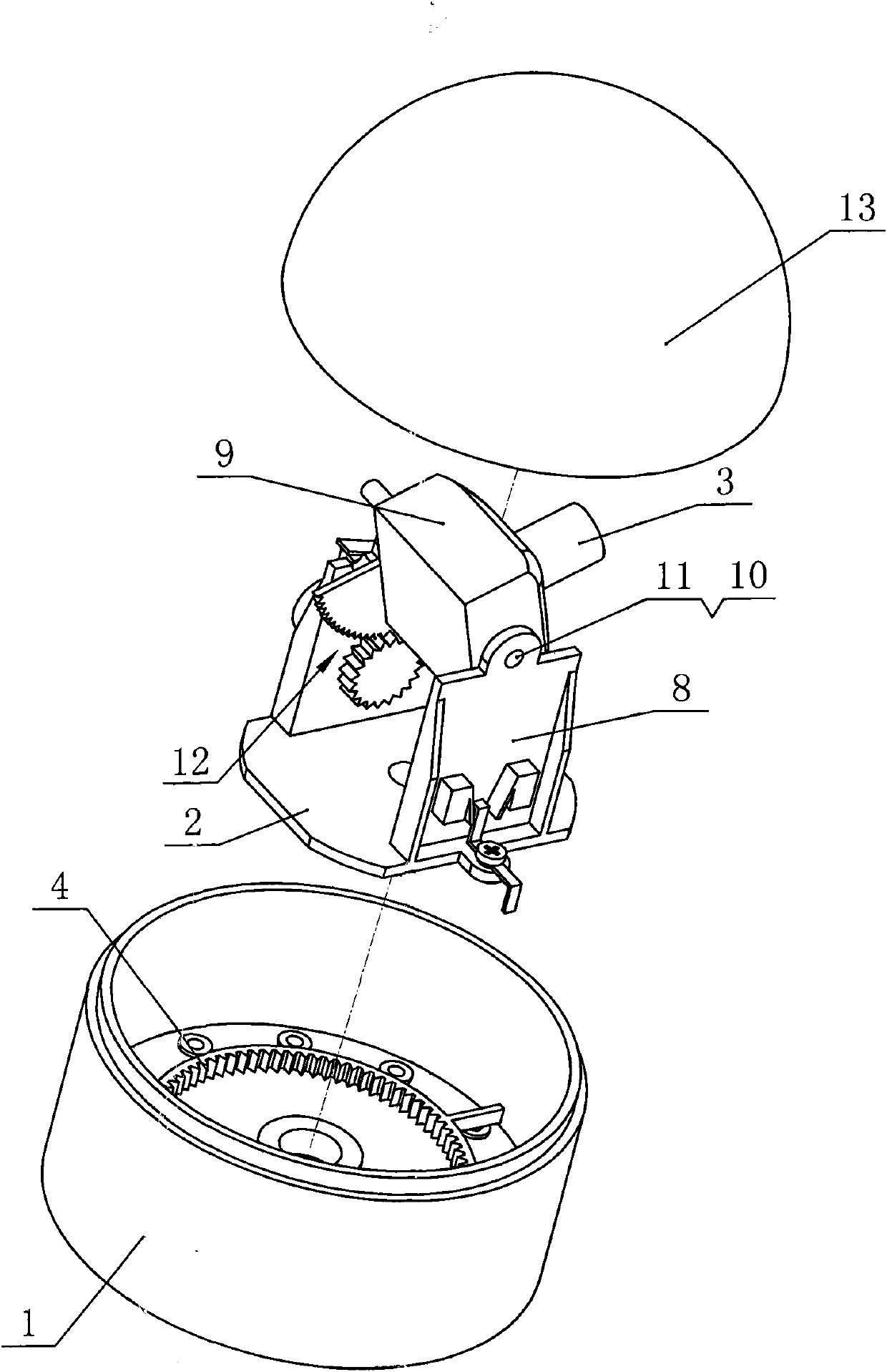

[0014] The high-precision positioning pan / tilt includes a horizontal rotation platform and a vertical rotation platform as well as a horizontal drive motor, a vertical drive motor and a controller. Such as image 3 As shown, the horizontal rotating platform includes a cylindrical base 1 and a rotating platform 2, and the wall height of the cylindrical base 1 should be appropriate so as not to affect the activities of the camera 3 on the vertical rotating platform. The bottom of the base 1 is provided with a circle of inner gear ring 4, and the center position of the inner gear ring 4 on the bottom of the tube is provided with a bearing. The rotating platform 2 is disc-shaped. There is a fixed central shaft 5, the central shaft 5 can be made into a tubular shape, and a number of cut grooves are arranged along the pipe wall to make the pipe wall have a certain elasticity. It is connected to the rotary platform 2 in the bearing hole, and a gap is provided at the position matchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com