Magnetofluid disc brake

A magnetic fluid and disc brake technology, which is applied in the field of brake devices, can solve the problems of unfavorable environmental protection, easy loosening of hydraulic joints, and easy oil leakage of hydraulic systems, so as to save hydraulic oil resources and benefit the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing, the present invention is further described:

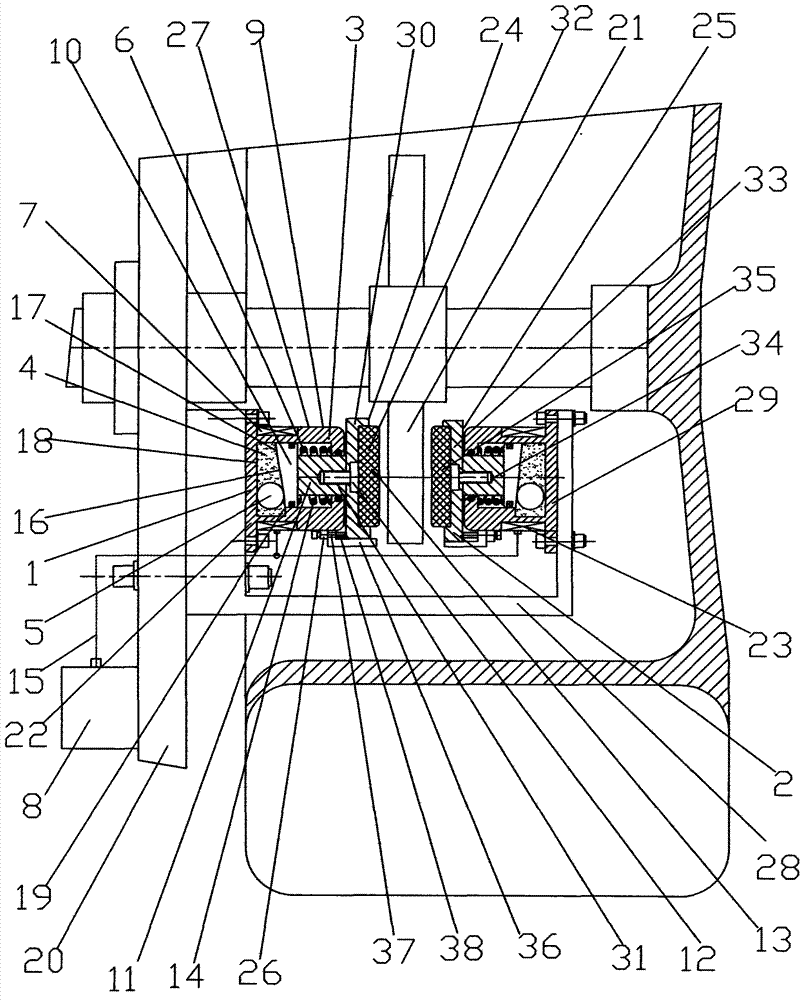

[0010] figure 1 A schematic structural diagram of a magnetic fluid disc brake is shown. A magnetic fluid disc brake includes a magnetic fluid brake drive device 1 and a brake device 2. The magnetic fluid brake drive device 1 includes a brake cylinder 3, a magnetic fluid 4, and a floating member 5. , an elastic element 6, an electromagnetic coil 7 and a controller 8; the brake cylinder 3 includes a cylinder body 9, a piston 10 and a piston rod 11, and the piston 10 is connected to the piston rod 11; the brake device 2 includes a brake seat 12 and a brake pad 13, The brake seat 12 is connected to the brake pad 13, the piston rod 10 is connected to the brake seat 12, the magnetic fluid 4 and the floating member 5 are arranged in the cylinder body 9, and the elastic element 6 is arranged between the piston 10 and the cylinder top 14 of the cylinder body 9, Electromagnetic coil 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com