Sorting system

A sorting system and pre-sorting technology, applied in the field of logistics, can solve problems such as slow results, difficult recruitment, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

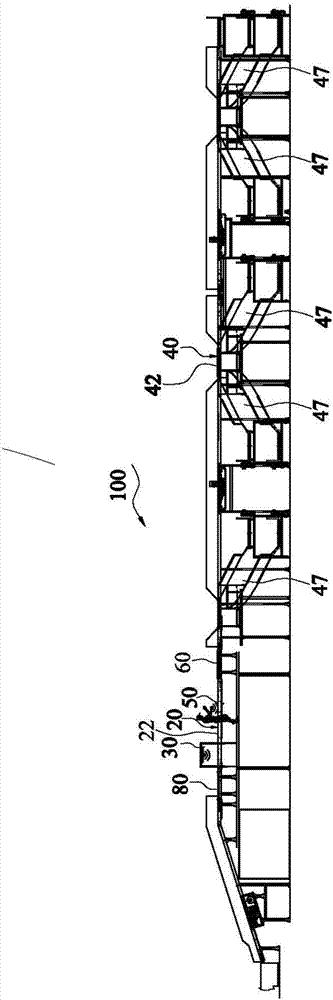

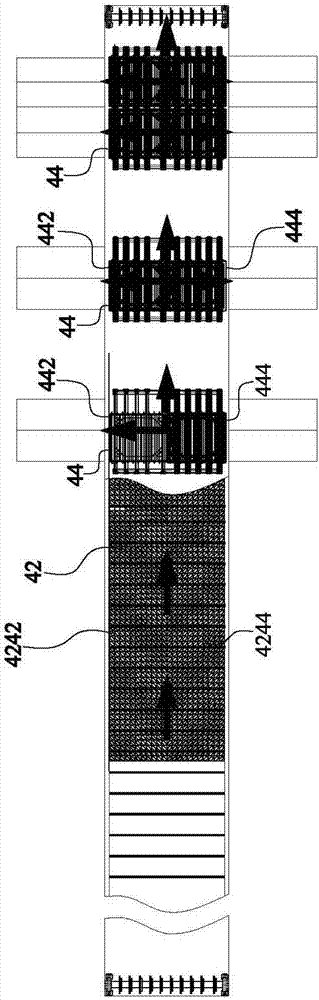

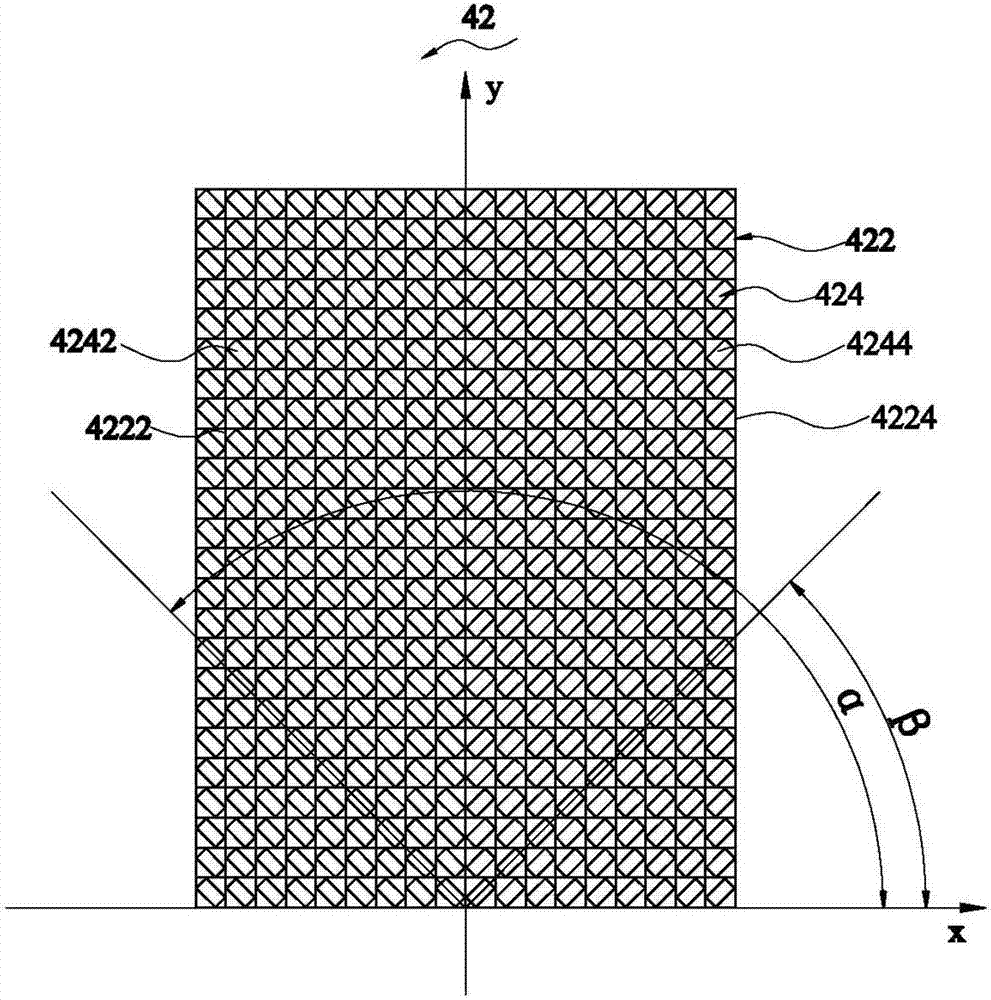

[0024] Such as Figure 1 to Figure 5 As shown, the sorting system 100 of an embodiment of the present invention includes: a conveying device 20 for conveying objects to be sorted, a sorting device 40, a position sensor for detecting and correcting the position of the objects to be sorted, and controlling the sorting device to divide Selected control system. The conveying device 20 includes: a conveying belt 22 and a conveying power for driving the conveying belt 22 to convey objects to be sorted. The sorting device 40 includes: a sorting conveyor belt 42, a jacking roller 44 arranged below the sorting conveyor belt 42 and frictionally rolling with the sorting conveyor belt 42 for sorting, driving the jacking roller 44 to move up and down for sorting The lifting power element 46, the sorting and conveying power element that drives the sorting conveyor belt 42 to rotate to transport the objects to be sorted. The sorting conveyor belt 42 includes: a base belt 422 and a pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com