A normal interface rigidity prediction method considering three-dimensional fractal

A technology of interface stiffness and three-dimensional surface, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as low efficiency and poor accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

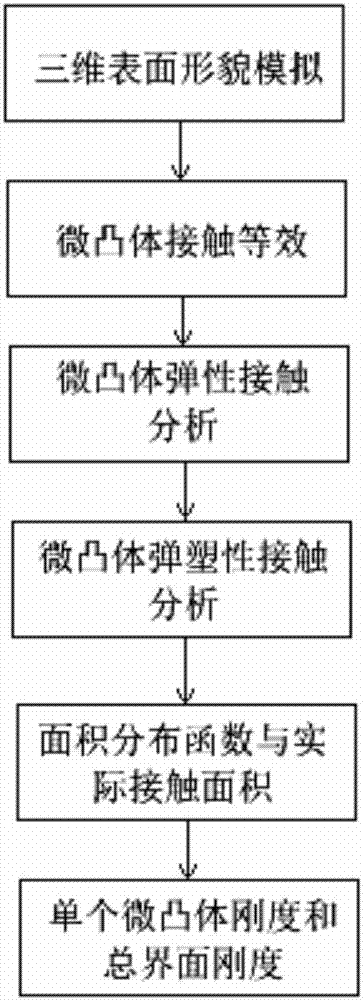

[0045] Such as figure 1 As shown, a kind of normal interface stiffness prediction method considering three-dimensional fractal of the present invention comprises the following steps:

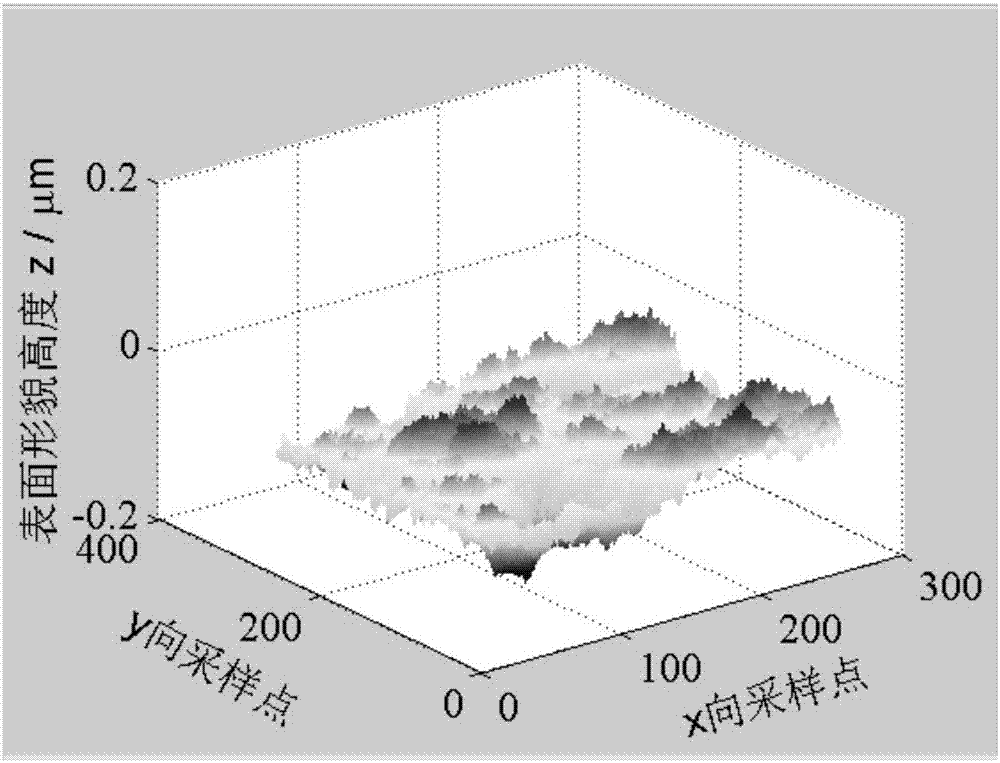

[0046] 1) Three-dimensional surface topography simulation: improve the function describing the two-dimensional fractal curve into a correction function for simulating the three-dimensional fractal topography, and express the amplitude difference between the peak and the trough described by this function as the contact deformation δ=2G D-2 (lnγ) 0.5 (2r′) 3-D , where D is the fractal dimension of the three-dimensional surface topography, 2<D<3, G is the fractal roughness of the surface topography, γ is the frequency density parameter, and r′ is the cut-off radius of the asperity;

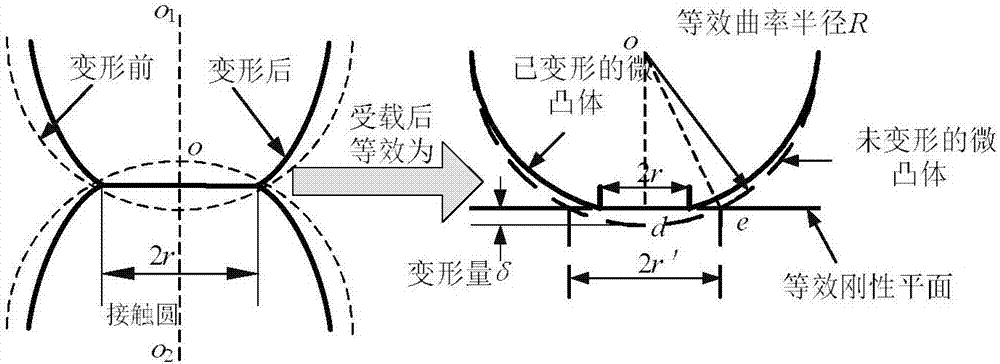

[0047] 2) Asperity contact equivalent treatment: if the contact between two rough asp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com