Deflective roller friction pair lubricating oil film measurement experiment table

A technology of rollers and cylindrical rollers, applied in the field of experimental equipment for measuring the lubricating oil film of skewed roller friction pairs, can solve the problems of large left-right difference, large line speed difference, asymmetric load distribution, etc., and achieve increased reliability and operation The effect of convenience and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the content, purpose, and technical solution of the present invention easier to understand clearly, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

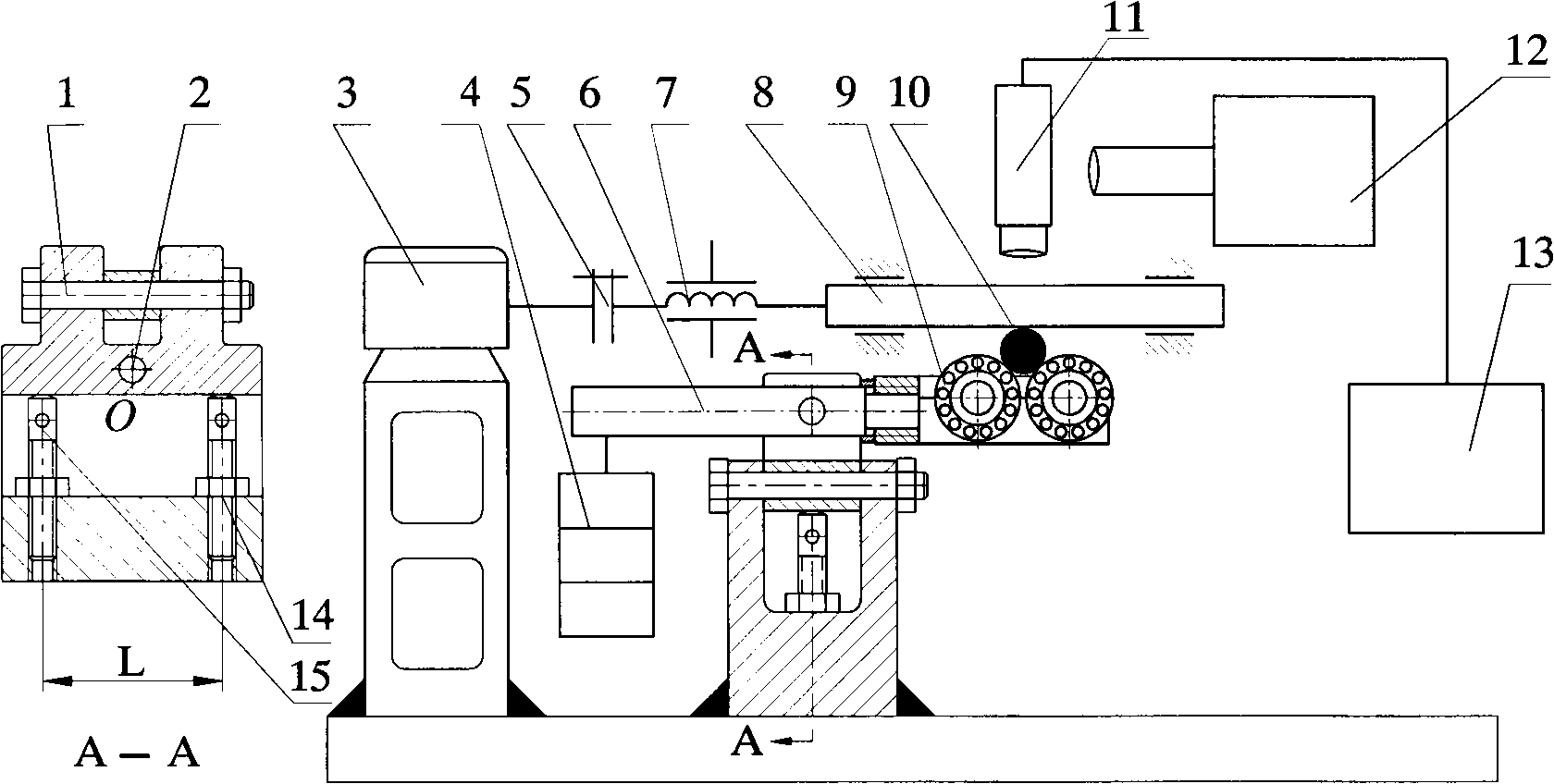

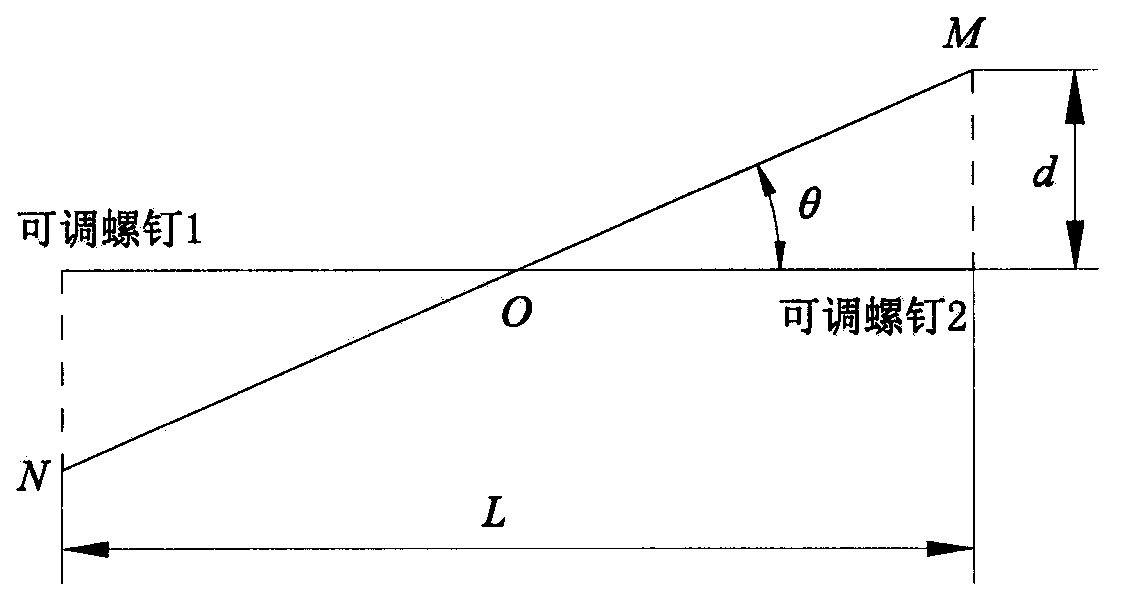

[0026] Such as figure 1 As shown, the servo motor 3 drives the sliding block 8 equipped with flat glass through the ball screw 7 to move linearly along the straight raceway, and the law of movement change is controlled by the servo motor 3. After the load 4 is loaded and amplified by the lever 6, the test roller 4 is supported by the roller bearing roller 9 to act on the flat glass, and the flat glass 8 drives the roller 10 of the test piece to rotate. Due to the heavy load, generally working above 1000N, the friction force generated between the test piece and the flat glass is sufficient to overcome the rolling friction of the supporting bearing roller and form pure rolling. The test roller 10 is supported by a rolling bearing 9. A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com