Method for processing rectangular aluminum alloy waveguide by multi-pass rolling drawing

An aluminum alloy and waveguide technology, applied in the field of mechanical processing, can solve the problems of lack of technical data, lower manufacturing costs, scratches on the surface of pipes, etc., and achieve the effects of centralized processes, reduced contact friction, and large deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

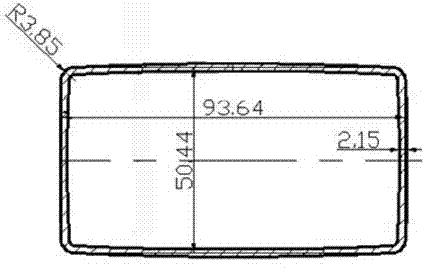

[0036] On the basis of ordinary roller drawing, the present invention improves the roller group, turns one group of rollers into multiple groups of rollers side by side, and designs the arrangement scheme of the roller group (such as Figure 11 shown). In this new processing method, pipes with different cross-sectional shapes can be obtained by changing the hole shape on the rollers and adjusting the distance between the rollers. The rectangular aluminum alloy waveguide is formed by a new rolling drawing method, and the flow function is introduced in the second rolling process to design the streamline of the roller arrangement, and finally determine the geometric shape of the roller group. Specific examples are as follows:

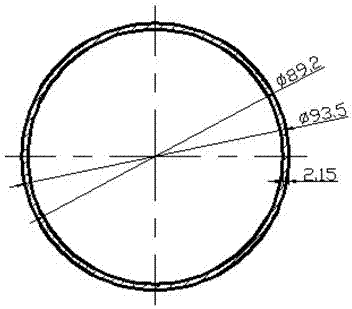

[0037] ①The round tube Φ93.5 / Φ89.2×2.15mm is produced by hot extrusion (450℃) of cylindrical aluminum ingot, and the cross-sectional shape of the tube blank is as follows figure 1 ;

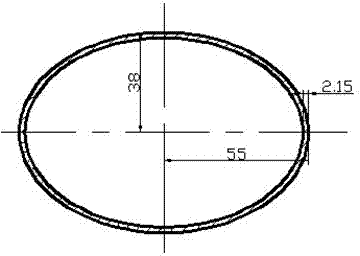

[0038] ②The first pass of rolling drawing (using 1 set of rollers) tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com