Open type TBM plane sliding stepping device and method

An open, flat technology, applied in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems of large excavation and backfilling, difficult rolling track, complex structure, etc., to achieve accurate sliding and labor-saving, accurate stepping direction. , the effect of fast stepping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to more clearly illustrate the technical solutions of the embodiments of the present invention, the following will briefly introduce the drawings that need to be used in the description of the embodiments. Obviously, the drawings in the following description are only some embodiments of the present invention. For those skilled in the art, other drawings can also be obtained based on these drawings without creative effort.

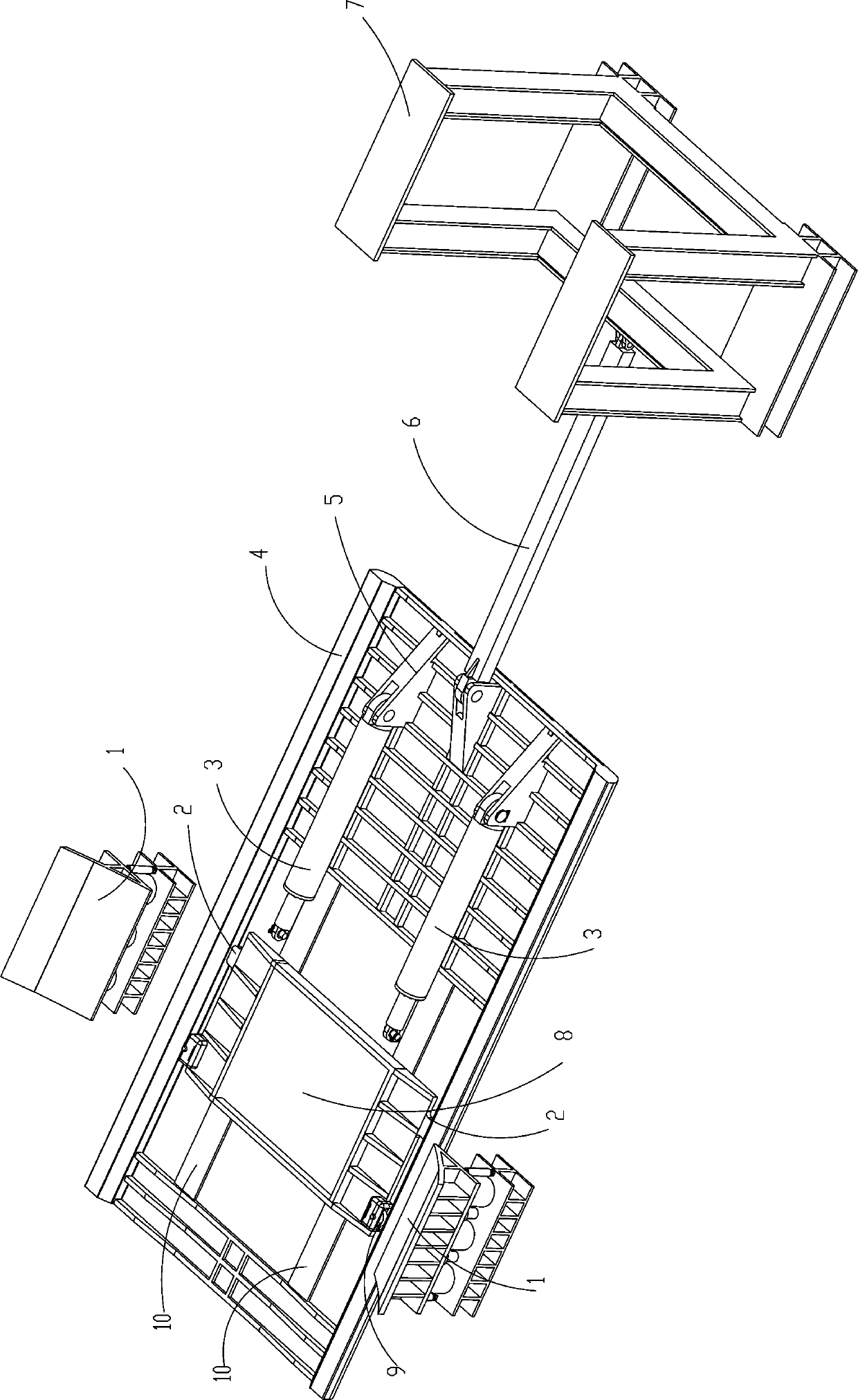

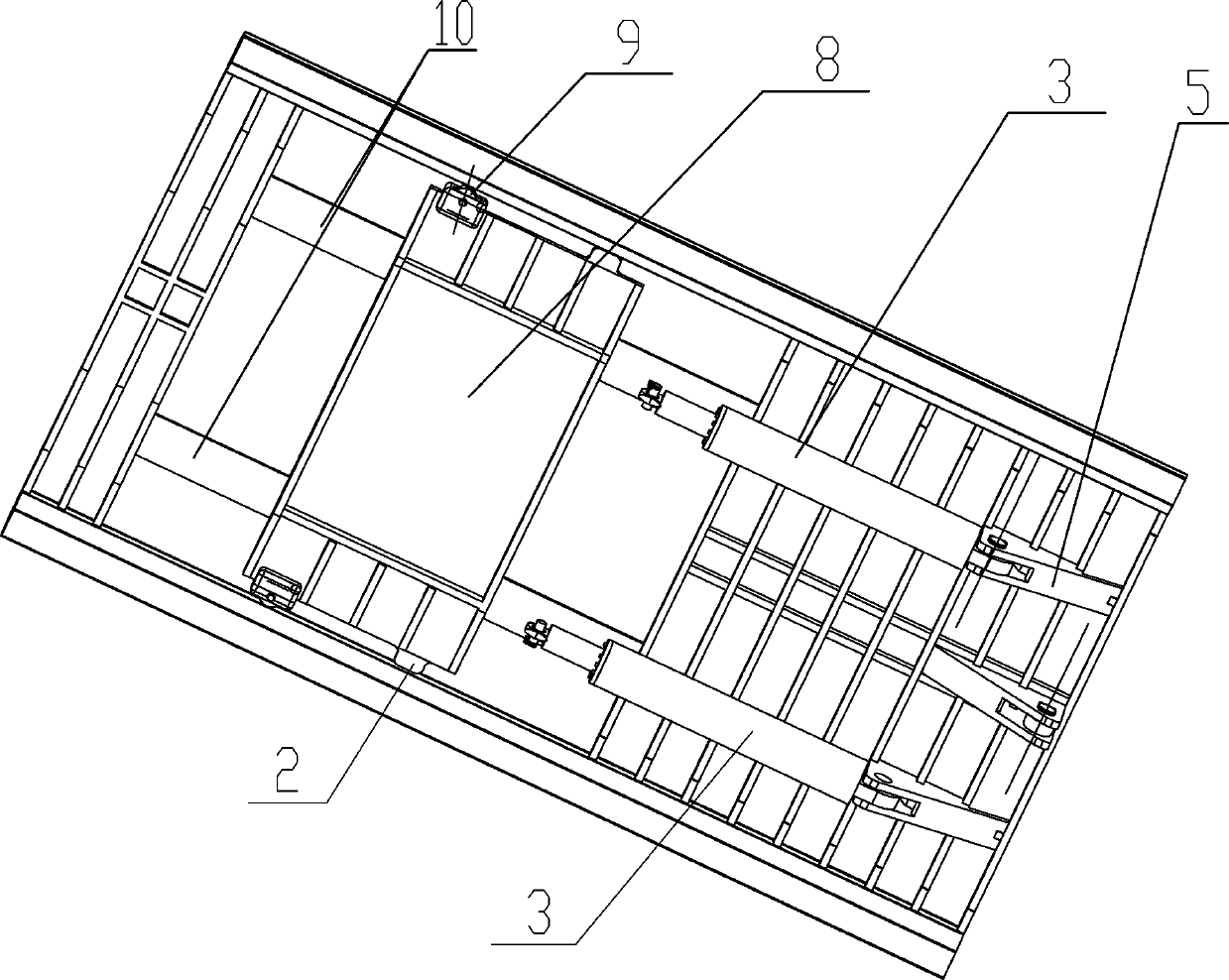

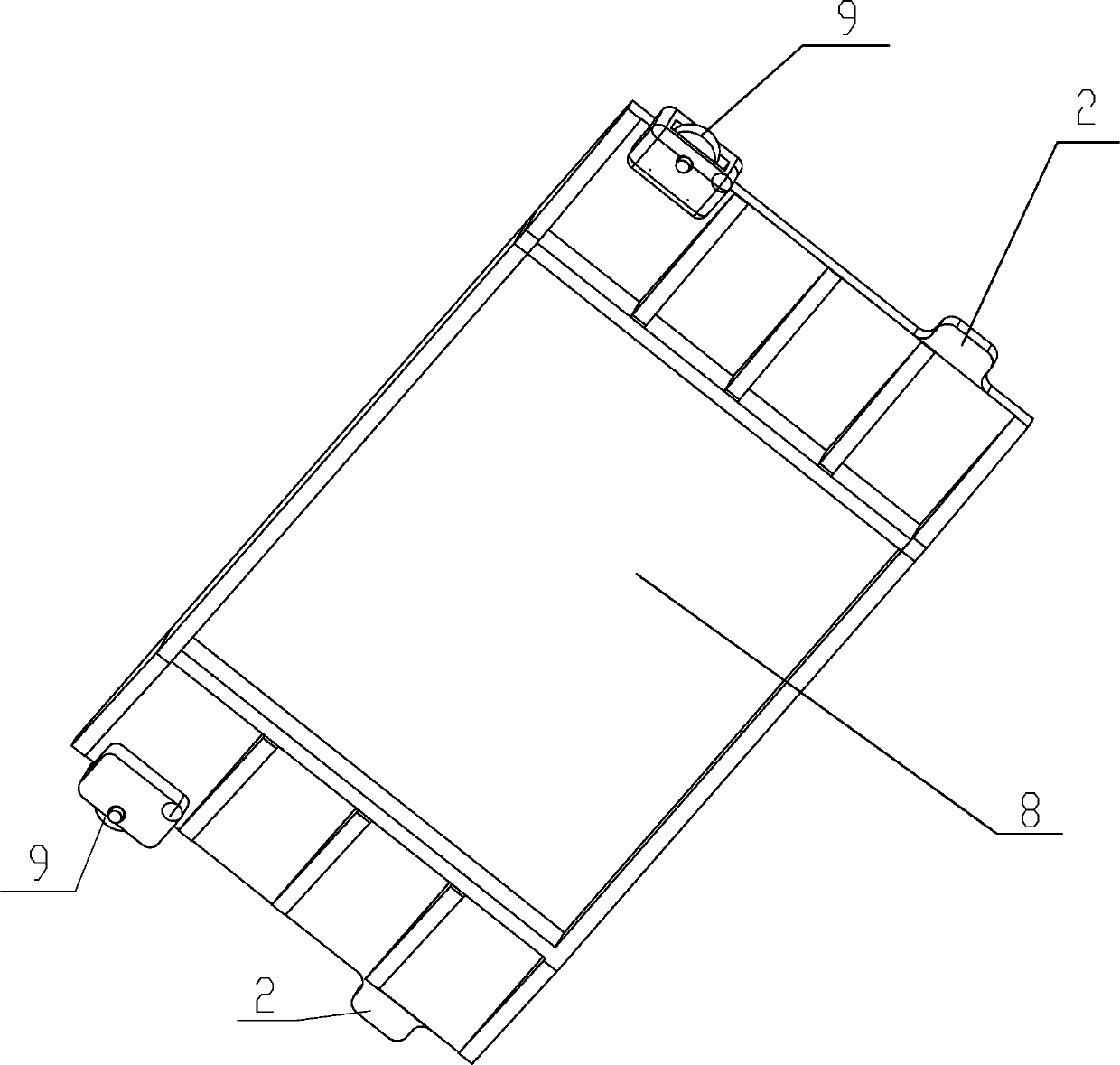

[0030] See attached figure 1 , The present invention is made up of seat plate 4, slide plate 8, propulsion hydraulic cylinder 3, lifting mechanism 1, pull rod 6 and rear bracket 7. The lifting mechanism 1 is arranged on both sides of the front portion of the seat plate 4, and the rear bracket 7 is connected to the rear portion of the seat plate 4 through a pull rod 6, and the two ends of the pull rod 6 are respectively hinged with the seat plate 4 and the rear bracket 7. A slide plate 8 for supporting the front of the TBM is provided on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com