Automatic locating and grinding method for general cylindrical grinding machine

A cylindrical grinding machine and automatic positioning technology, which is applied to grinding machines, parts of grinding machine tools, and machine tools designed for grinding the rotating surface of workpieces. problem, to achieve the effect of simplified adjustment, constant conversion point, and avoidance of mutual interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

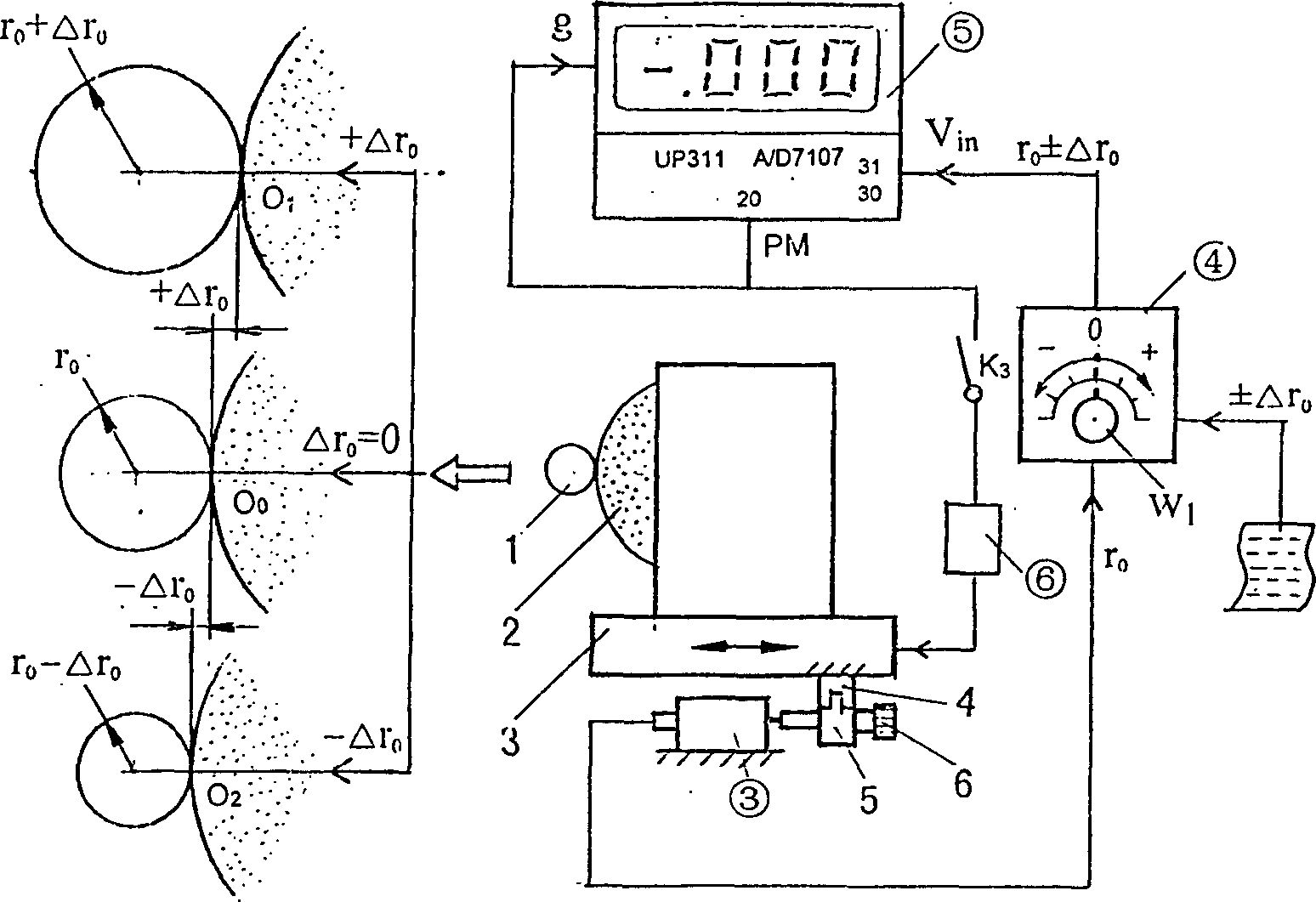

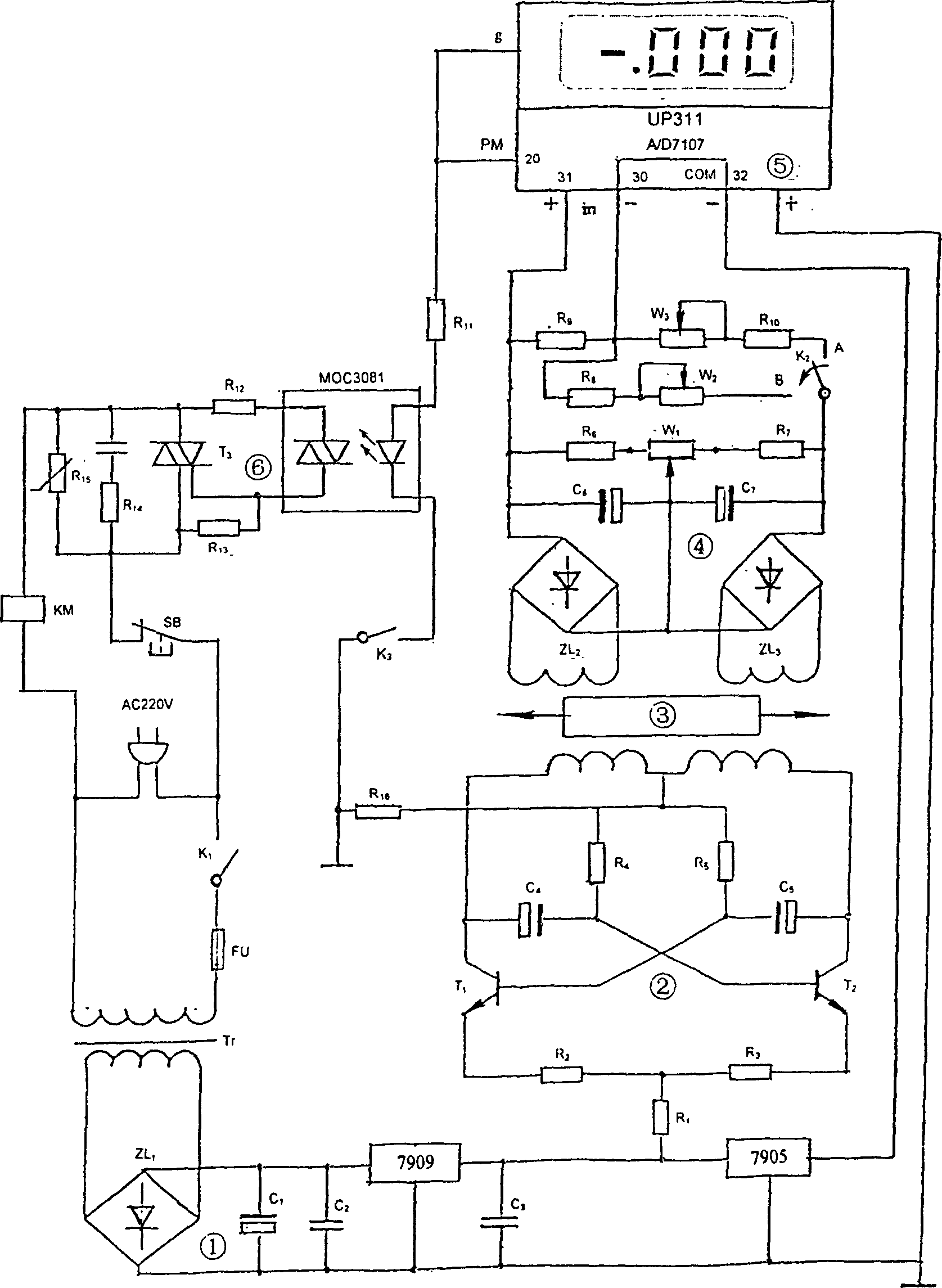

[0014] refer to Figure 1~2 , the present invention is composed of electromechanical two parts, the mechanical part includes a bracket 4, a rotating arm 5 and an adjustable ejector rod 6; the control device includes a DC power supply ①, a multivibrator ②, a sensor ③, a differential rectifier circuit ④, a digital panel meter ⑤ and power interface ⑥. The bracket 4 is fixed on the grinding wheel frame 3, the rotating arm 5 is connected with the bracket 4 through a hinge, and the adjustable ejector rod 6 is a micrometer with a scale value of 0.01mm, which is fixed on the rotating arm 5 and is used to change the machining diameter. Adjustment, the bracket 4, the rotating arm 5, the adjustable ejector rod 6 and the probe of the sensor ③ are centered, and after adjustment, they are fixed and moved together with the grinding wheel frame 3 being fed. The sensor ③ is fixed on the bed, constant, its primary coil is electrically connected to the multivibrator ②, and the secondary coil is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com