Patents

Literature

32results about How to "Good grinding precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

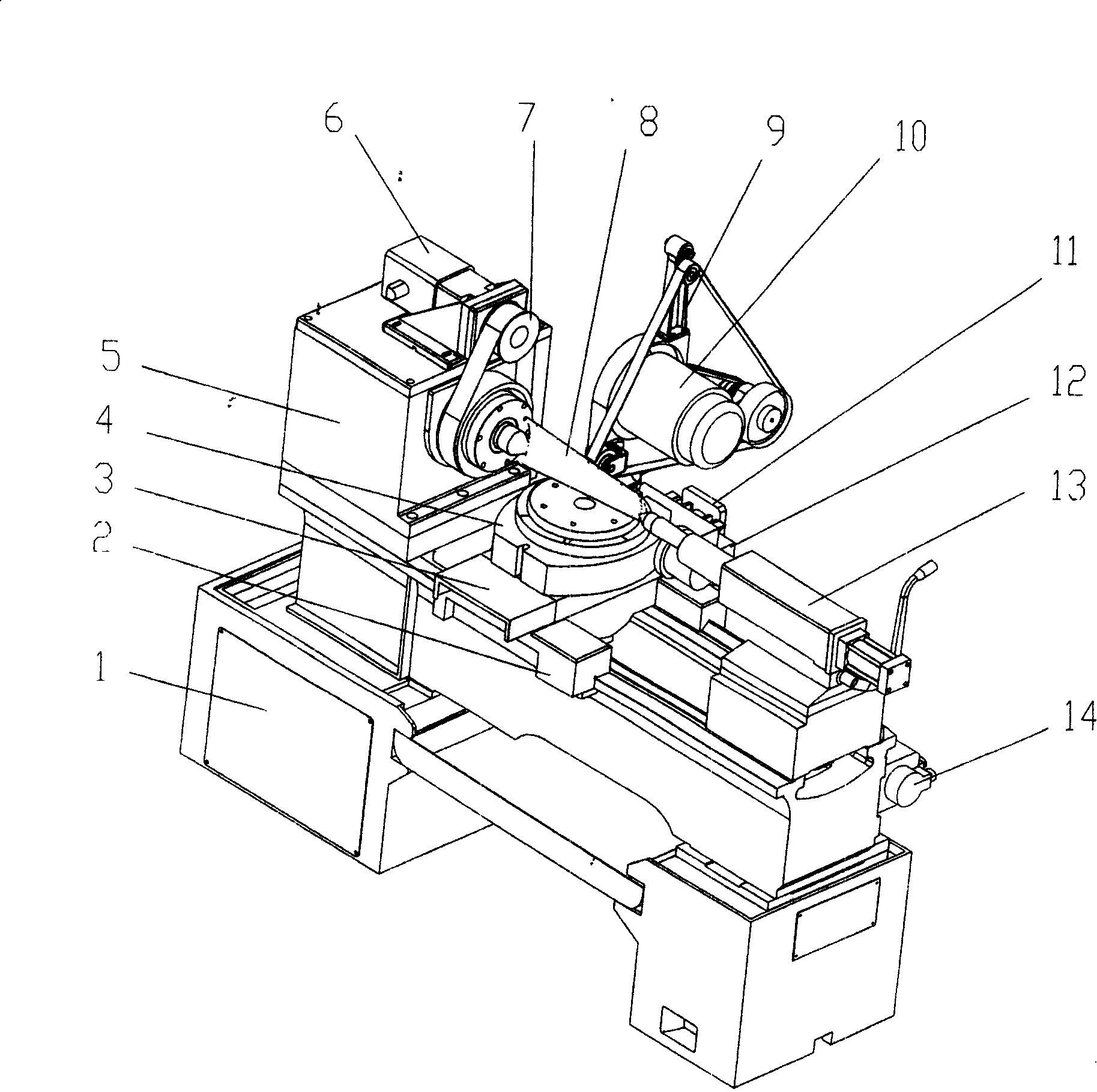

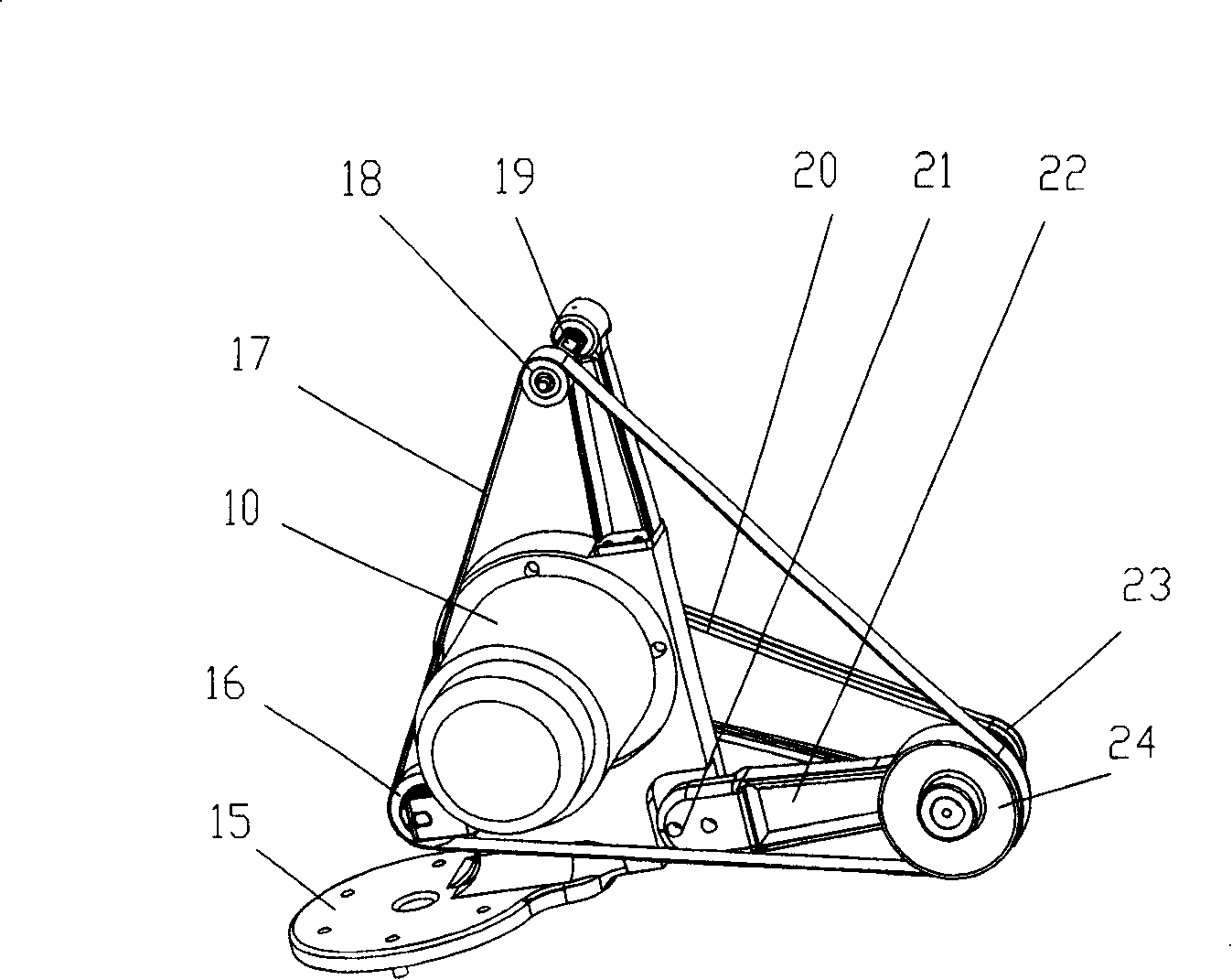

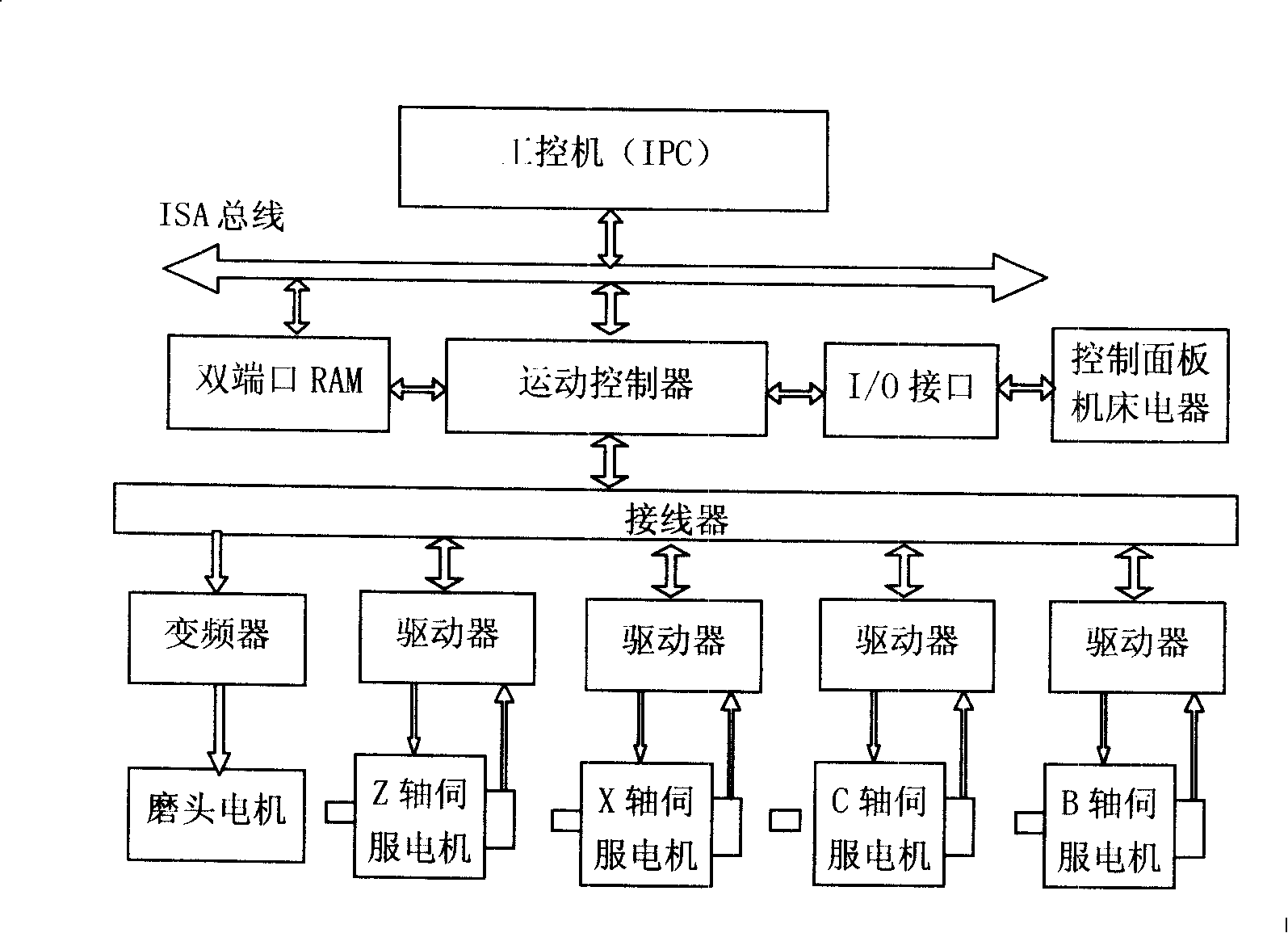

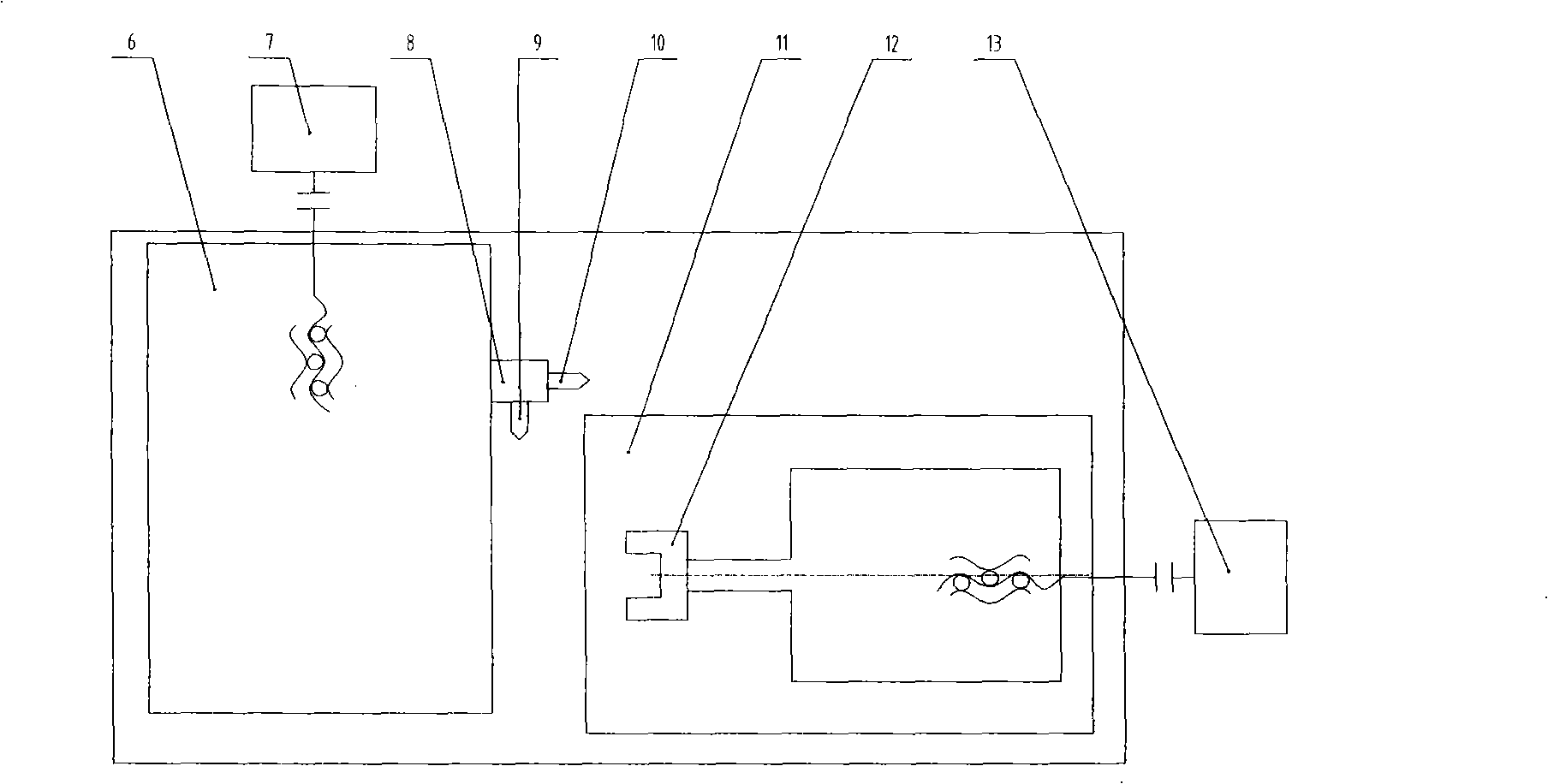

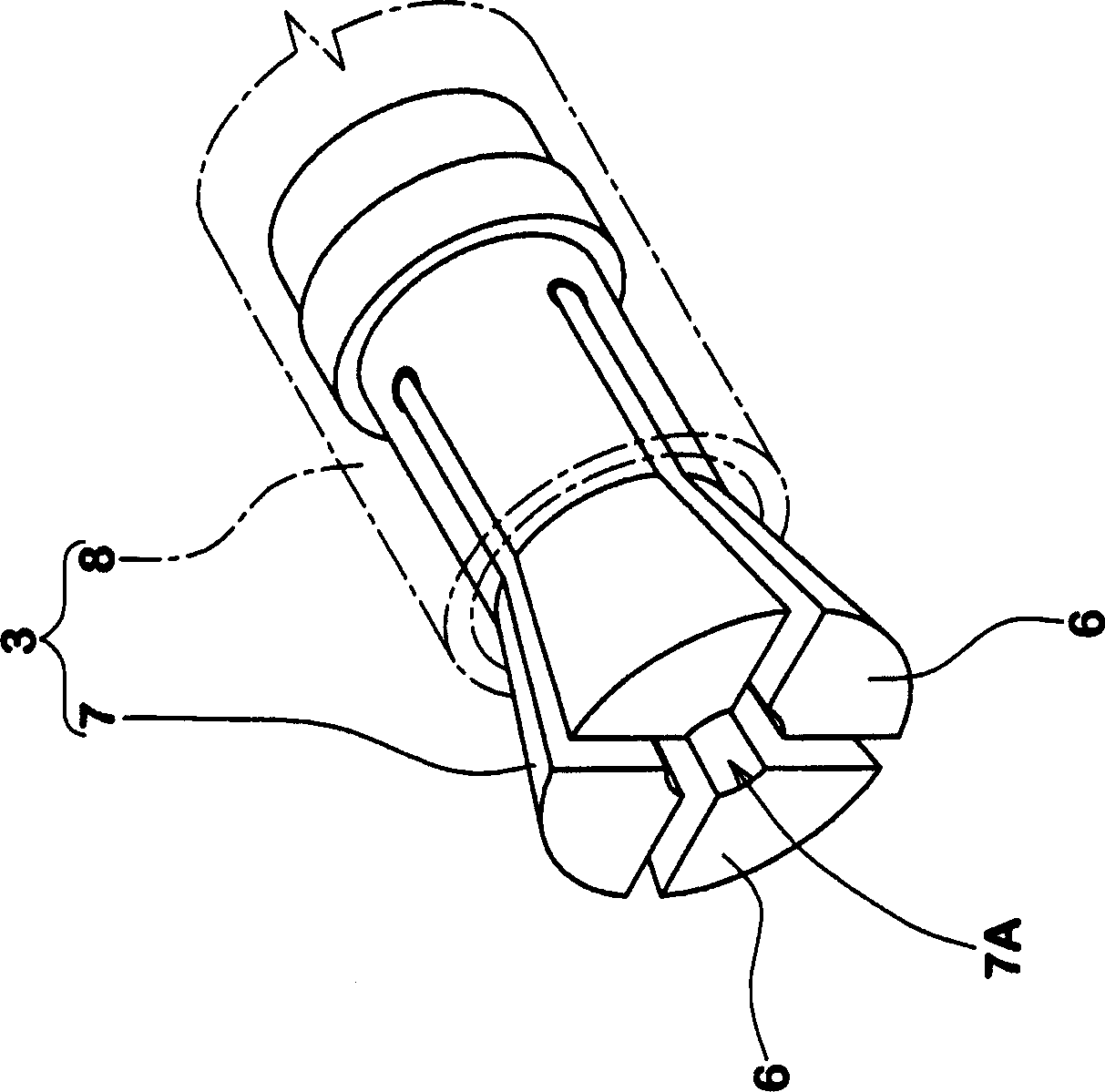

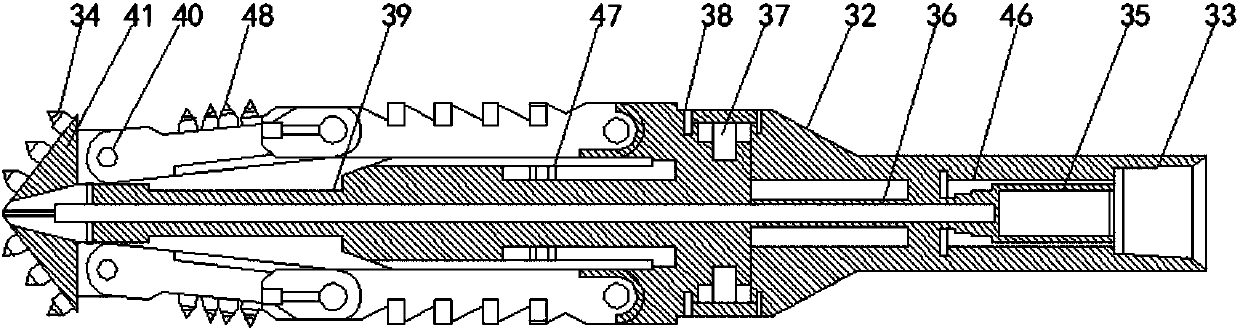

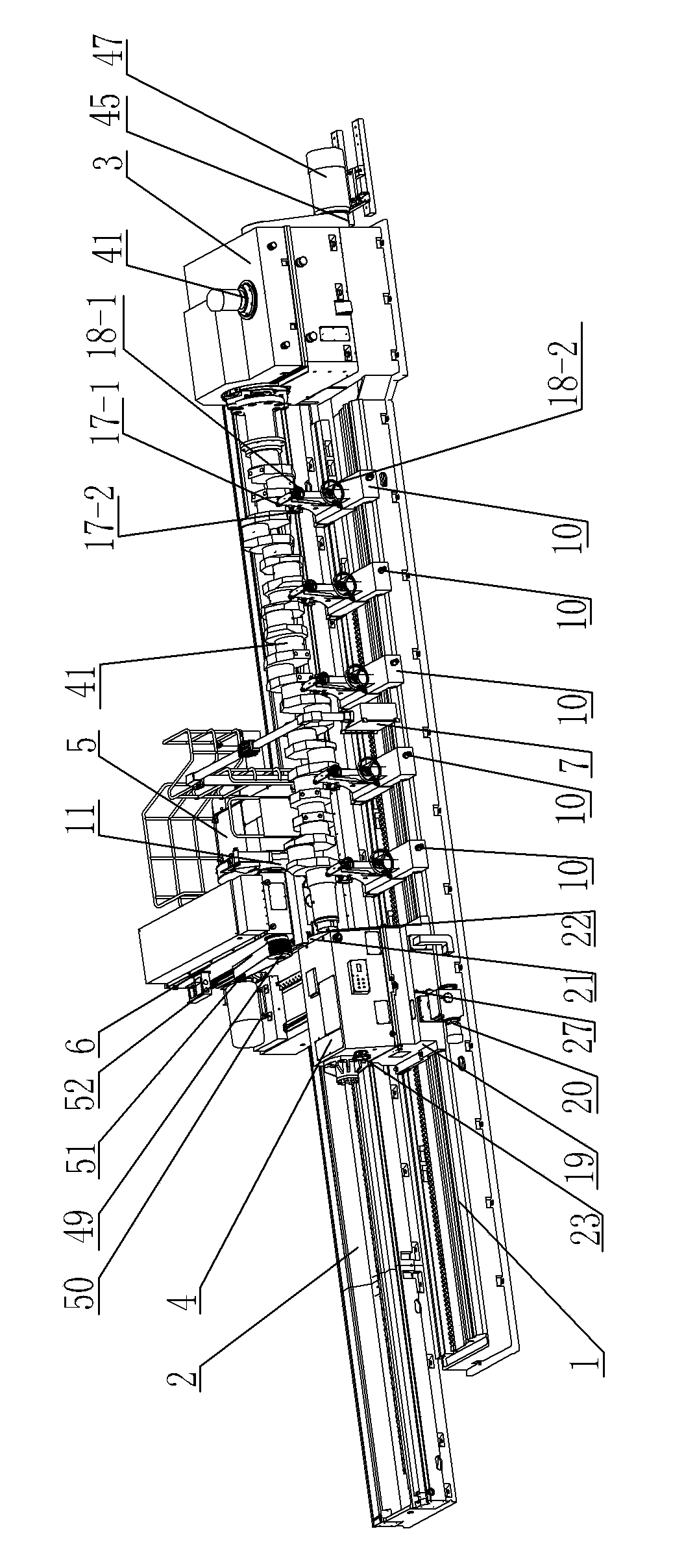

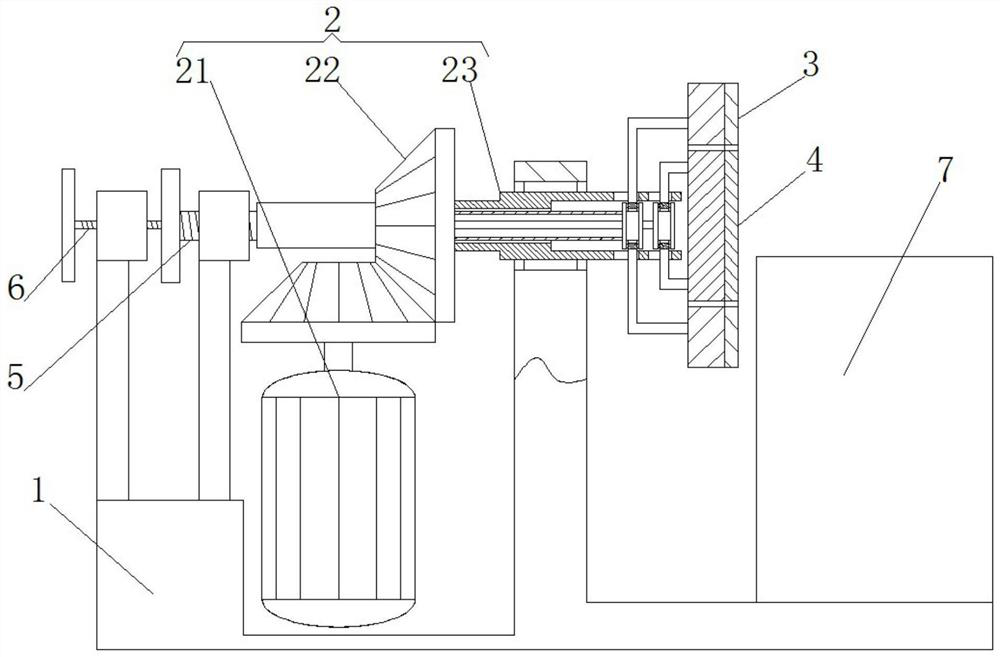

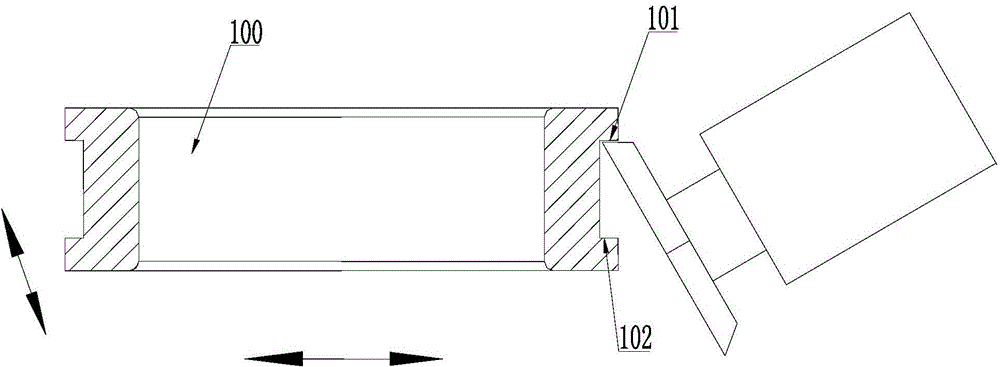

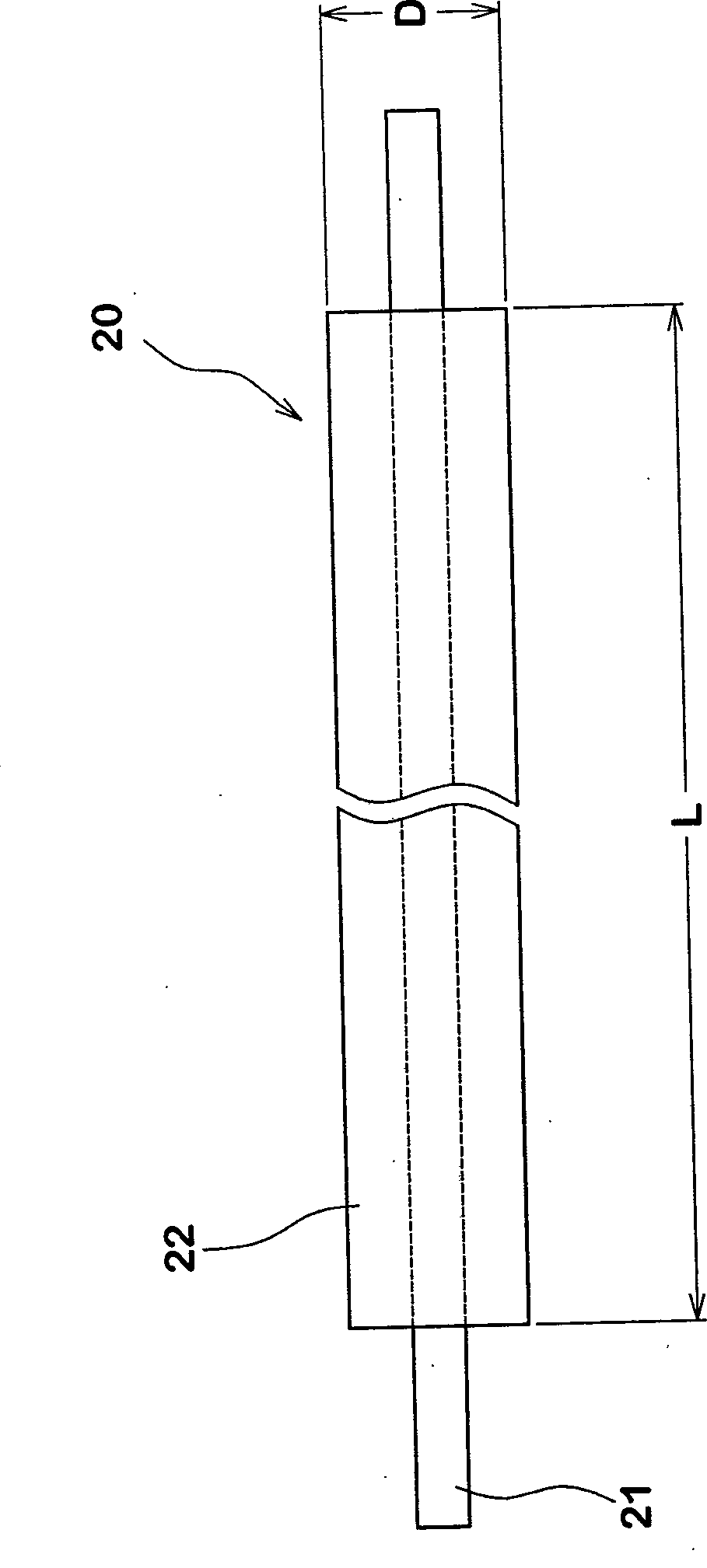

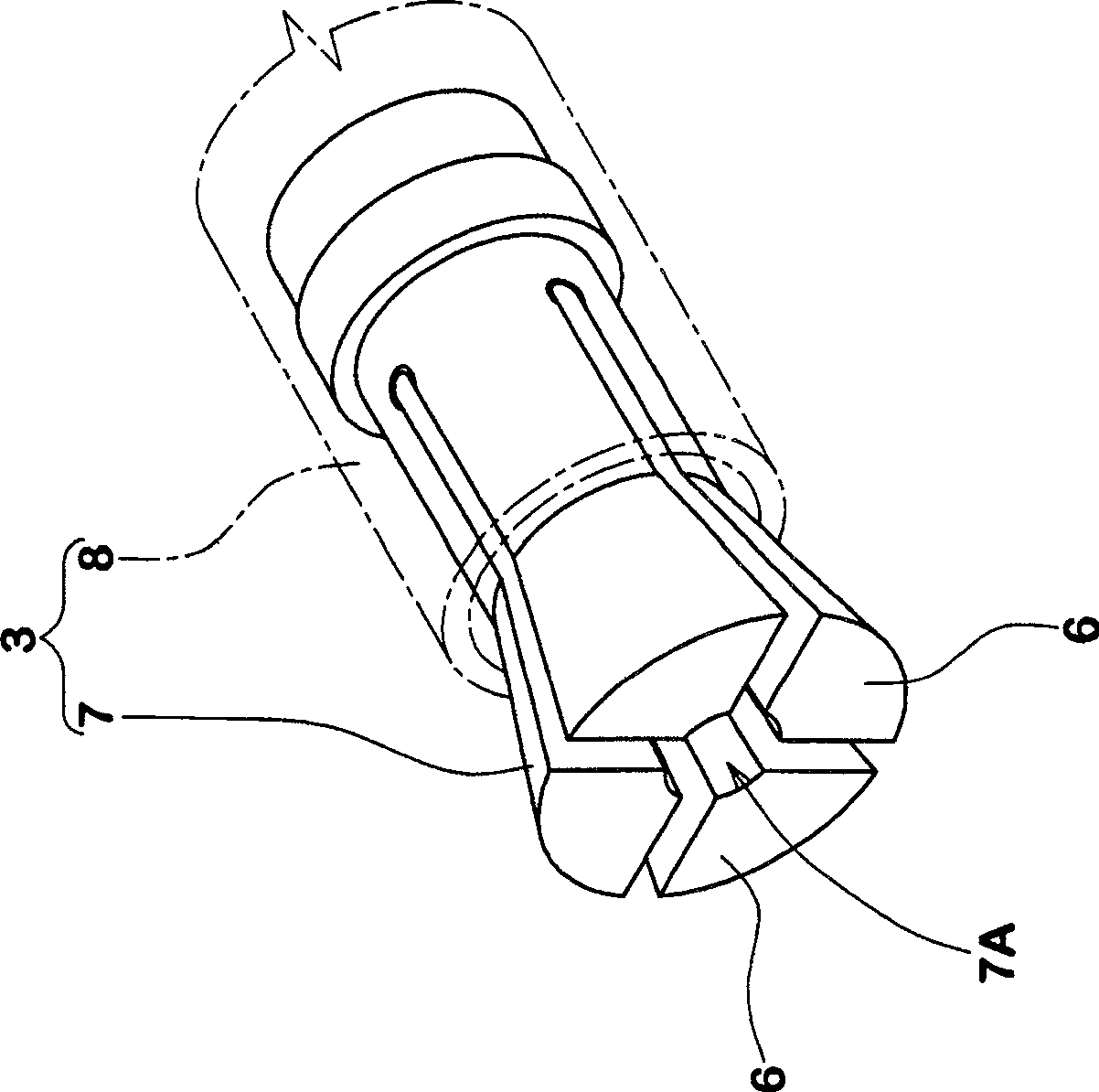

Turbine blade digital control abrasive belt grinding machine and operating method thereof

InactiveCN101234480AImprove grinding efficiencyGood grinding precisionBelt grinding machinesGrinding feed controlDigital controlSoftware modules

The invention discloses a turbine blade numerical control belt grinder and a control method thereof, which relates to a grinding and processing device of a turbine blade and the control method thereof, and is characterized in that: a belt wheelhead and an open numerical control system is provided on the basis of the basic parts of the original machine tool; the belt wheelhead is provided with a grinding belt tightening device and a transmission belt tightening device; a Z-axis serving motor drives a big carriage; an X-axis serving motor drives a small carriage; a C-axis drives a head frame; a B-axis drives a turret; a D-axis is a belt wheelhead motor; and each motor is connected with the control system; the control system is provided with a memory, a control circuit and a blade grinding and a controlling software module. During the operation, the original parameter is firstly input; then a blade grinding and controlling software module is automatically setting up by the system to generate a processing program, make error analysis and machining simulation; and finally a blade actual grinding processing is carried out. The turbine blade numerical control belt grinder is a five-axis and four-linkage numerical control belt grinder, and has the advantages of high efficiency, good accuracy, simple structure, low cost, and convenient control.

Owner:YANGZHOU UNIV

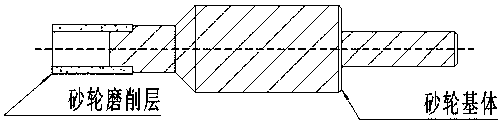

Grinding wheel applied to zirconia ceramic ferrule PC spherical surface and preparation method thereof

InactiveCN107650032ANot easy to breakImprove the finishAbrasion apparatusGrinding devicesChromiumHigh-density polyethylene

The invention relates to a grinding wheel applied to a zirconia ceramic ferrule PC spherical surface. The grinding wheel comprises a grinding wheel base body and a grinding layer, wherein the grindinglayer is mainly composed of an abrasive material, a resin binder and stuffing; the stuffing is made of polytetrafluoroethylene, high-density polyethylene and an active nano-polishing agent; the active nano-polishing agent is composed of the following raw materials of, by weight, 10%-30% of cerium oxide, 5%-15% of ferric oxide, 25%-40% of chromium dioxide and 20%-40% of flake graphite. The grinding wheel belongs to superfine powder grinding wheels, the requirements for curvature radius and high-surface quality of the ferrule PC spherical surface can be met, the grinding wheel is sharp, the shape retention property is good, the processing efficiency is high, and the no-dressing situation can be achieved during grinding.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

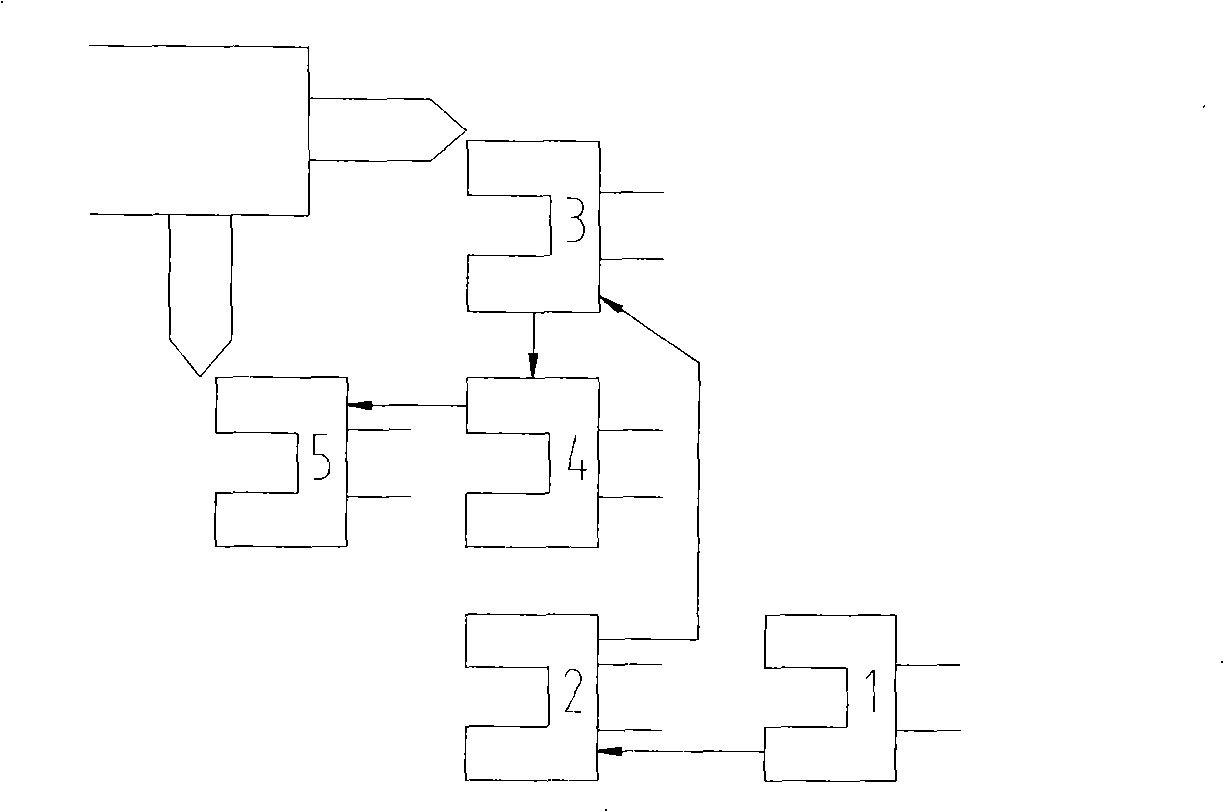

Abrasive wheel end face and cylindrical finishing method

InactiveCN101259600ARealize automatic trimmingGuaranteed trimming accuracyAbrasive surface conditioning devicesMotor driveEngineering

The invention discloses the method for trimming the end face and the excircle of a grinding wheel, By adopting the way of stepping linkage to trim the end face and the excircle of the grinding wheel, the grinding wheel needed to trim is fixed on a reciprocating planker by a grinding wheel head device, thus leading the grinding wheel head device to start and to drive the grinding wheel. While the excircle and the end face of the grinding wheel are fixed on a feeding planker, and the alteration of axial position of the grinding wheel is realized by a feeding stepping motor driving the feeding planker. The position of the reciprocating planker which is not moved is called a original position 1; after the trimming of the end face, the grinding wheel is moved from the position 1 to the position 2 axially, the grinding wheel which is then moved from position 2 to the position 3 radially, then the end face of the grinding wheel is trimmed through the radial movement; after the trimming of the end face of the grinding wheel, the trimming of excircle of the grinding wheel is started, the grinding wheel is moved from the position 3 to the position 4 axially, which is then moved from position 4 to the position 5 radially, at last the trimming of the grinding wheel is finished through the axial movement.

Owner:LUOYANG BEARING SCI & TECH CO LTD

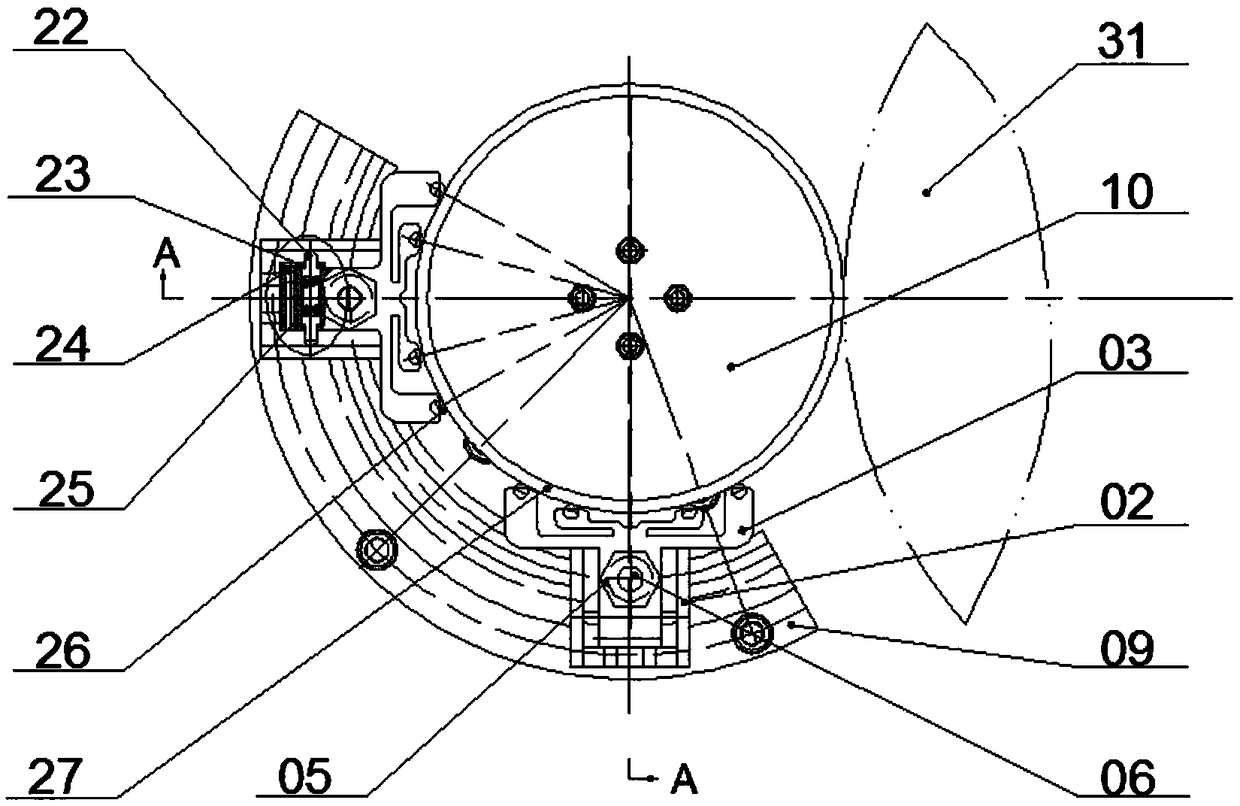

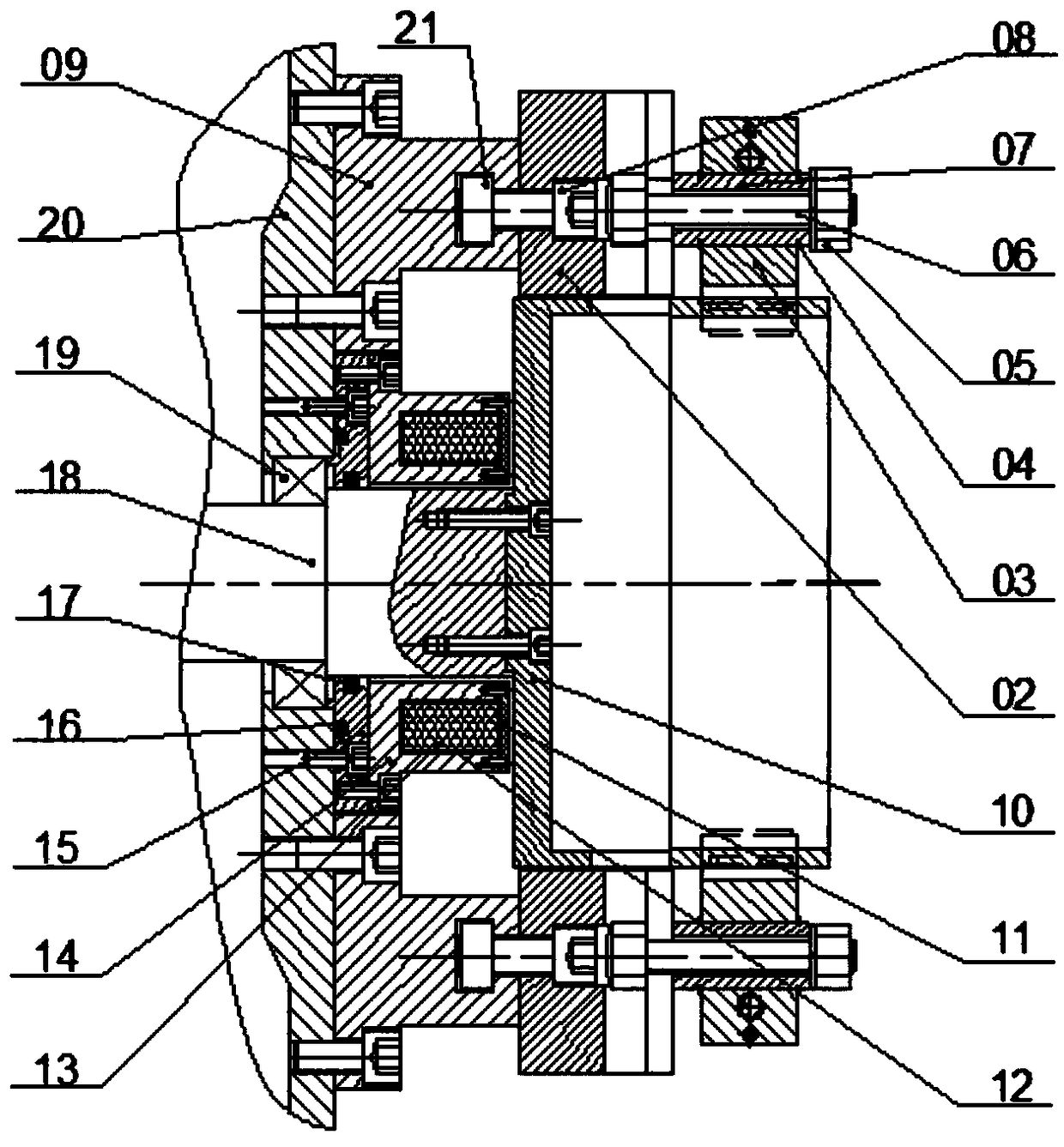

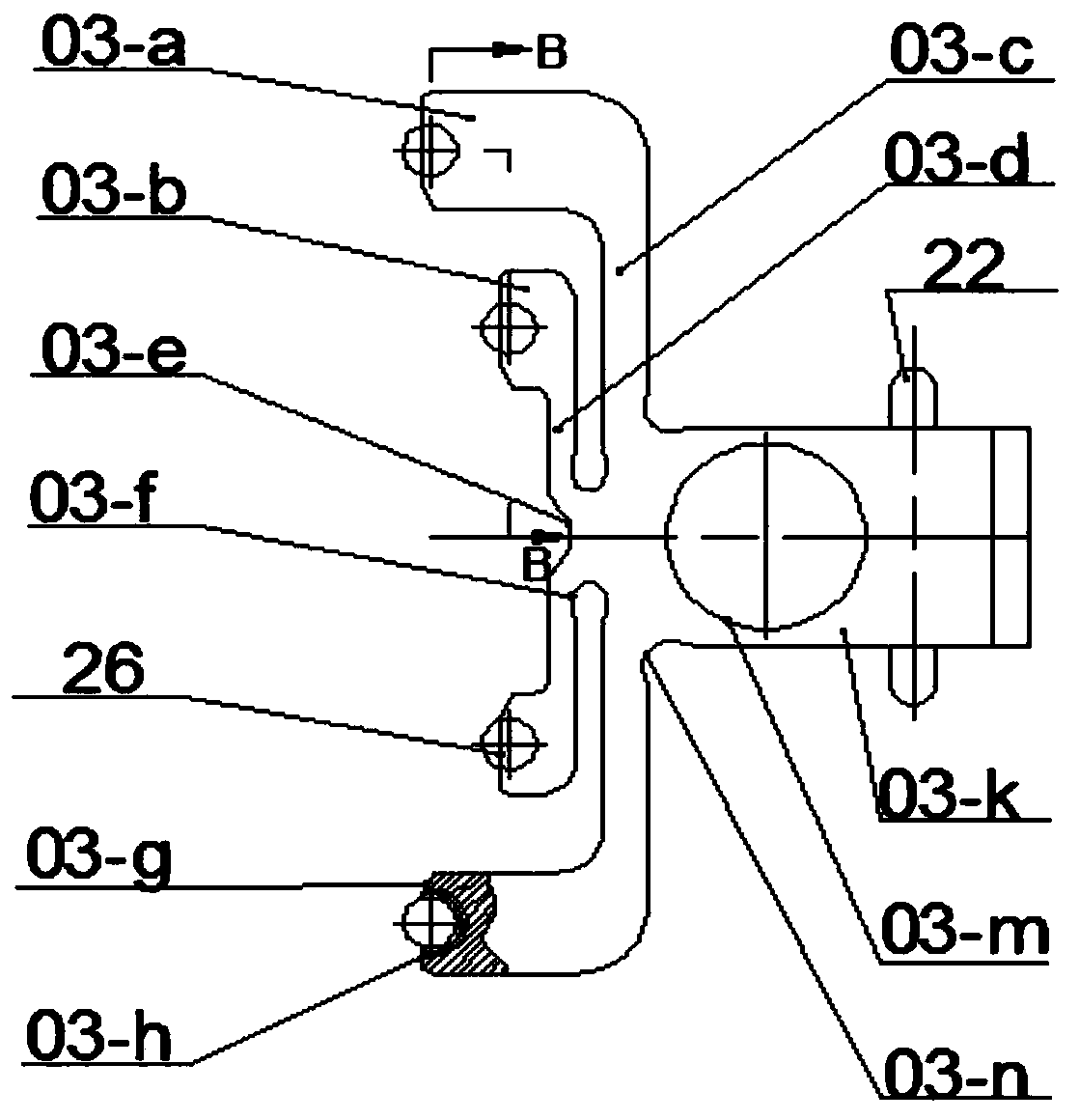

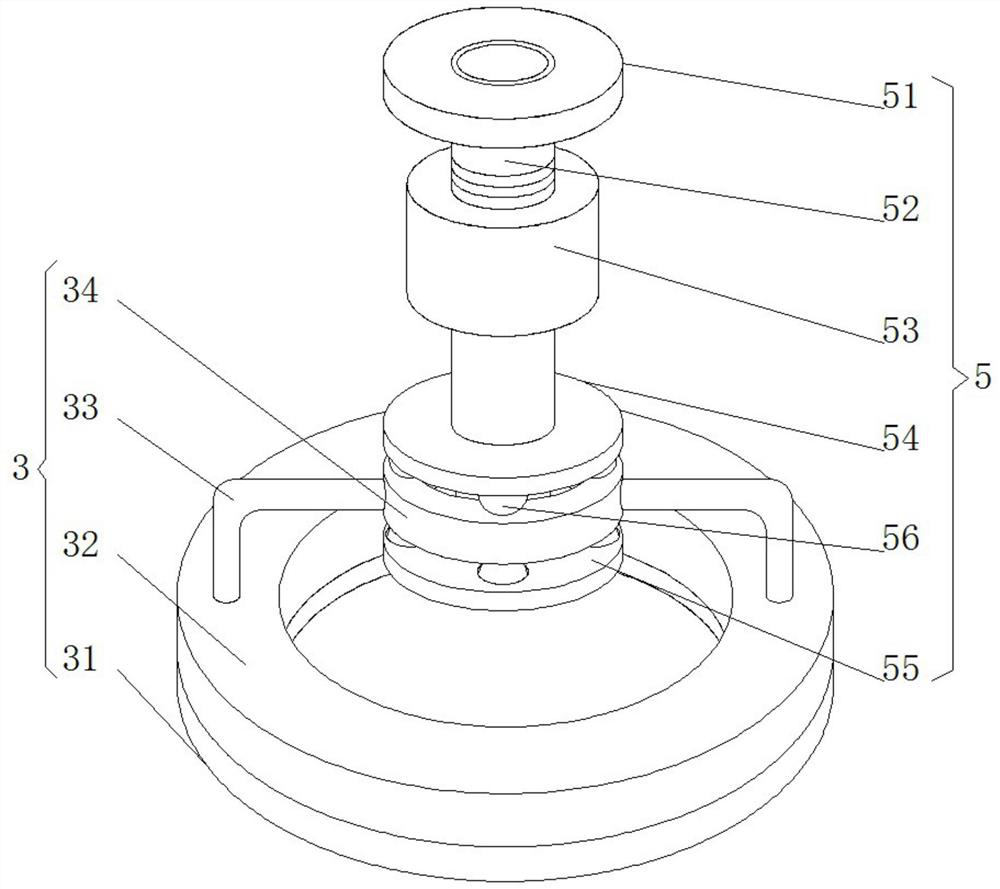

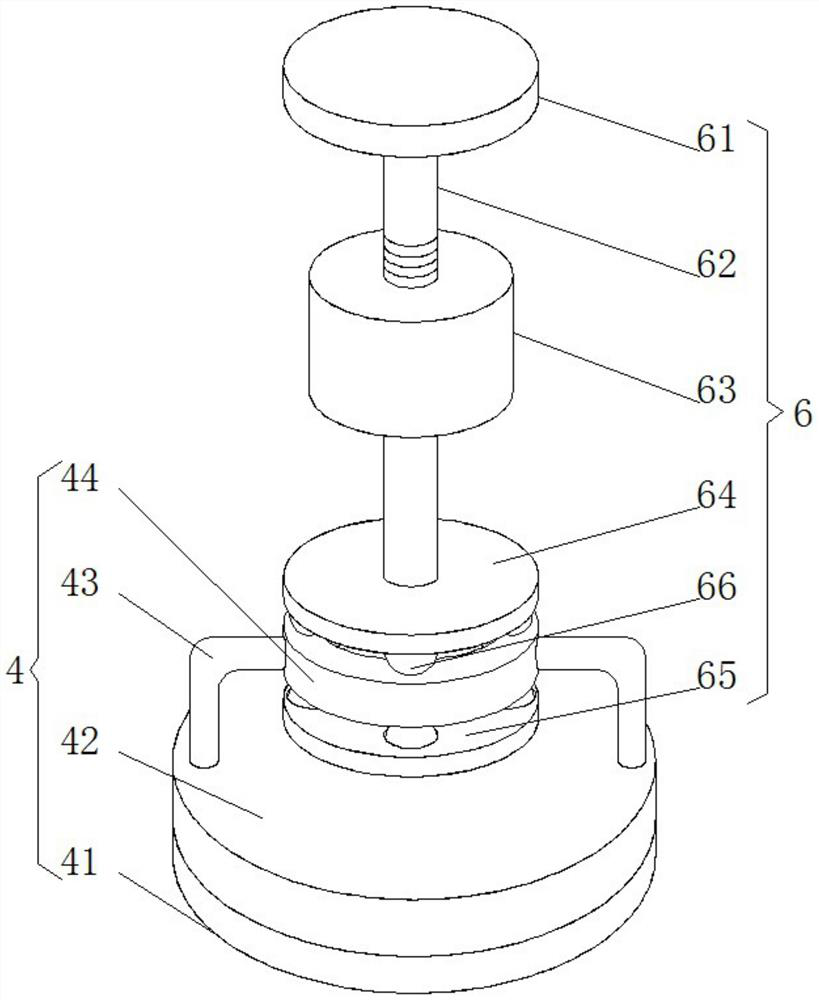

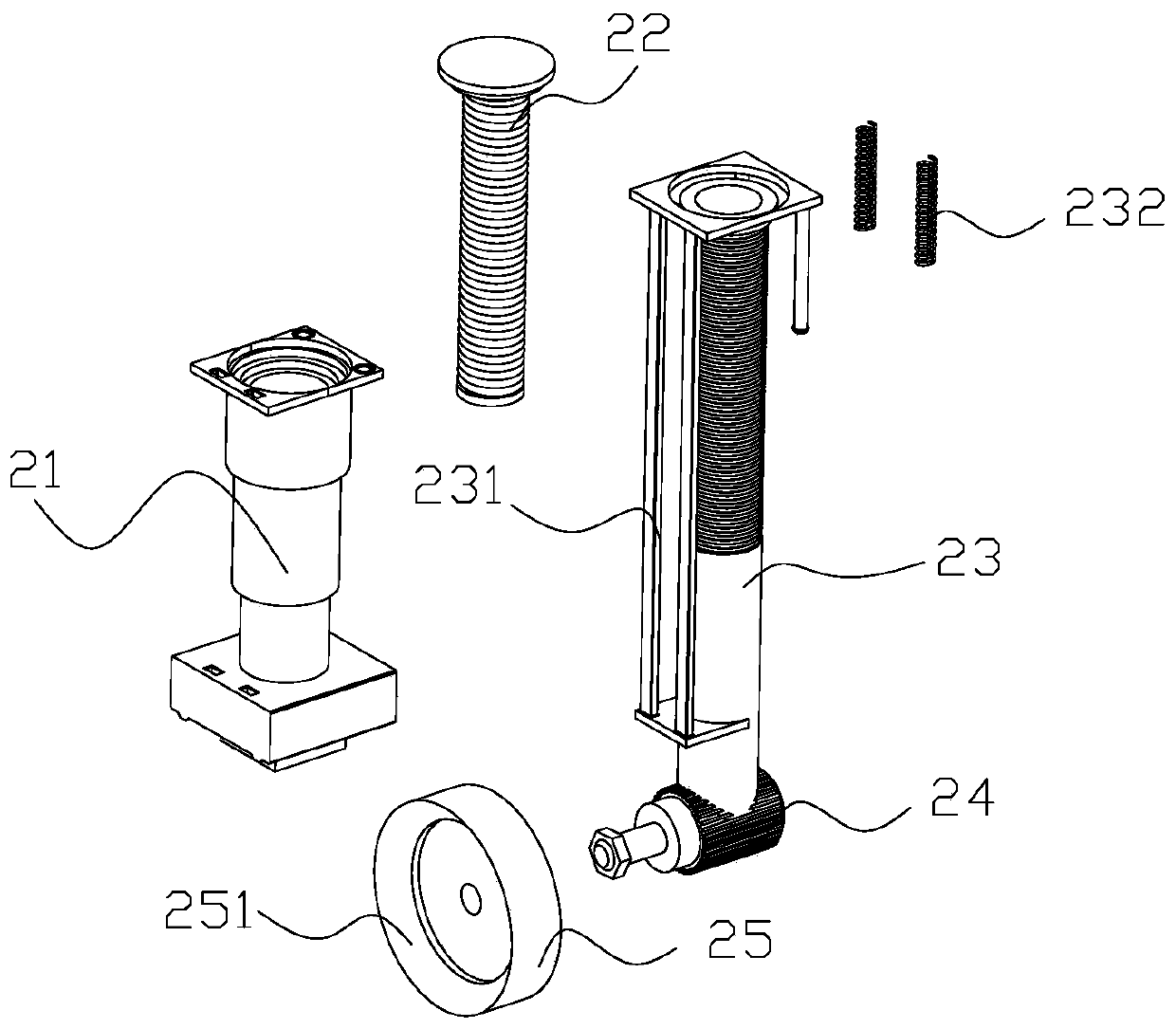

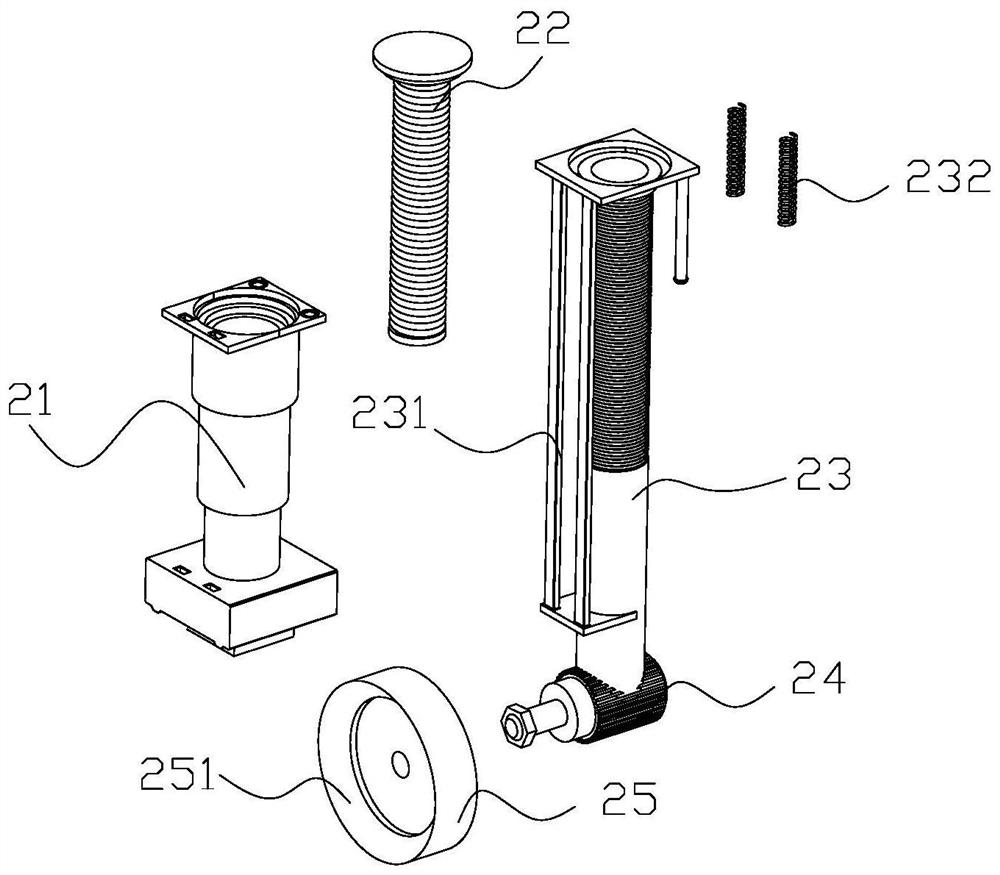

Elastic rolling floating support for centerless grinding of outer circle of annular part

PendingCN108655845ASmall elastic deformationAddress bearing marks and even superficial burnsRevolution surface grinding machinesRolling resistanceMagnetic poles

The invention discloses an elastic rolling floating support for centerless grinding of an outer circle of an annular part. The elastic rolling floating support comprises elastic supporting bodies, supporting sleeves, compressed springs, transition blocks and a supporting seat; the elastic supporting bodies press the supporting sleeves through T-shaped bolts to be connected to the transition blocks, the transition blocks are connected and fixed on the supporting seat of a machine tool shell, one end of each elastic supporting body is provided with a plurality of pairs of supporting heads, alloyballs are correspondingly arranged at the end parts of the supporting heads, and the other ends of the elastic supporting bodies are fixed on the supporting seat; and a coil shell is arranged on theinner side of the supporting seat, a coil is arranged in the coil shell, a sealing body is arranged outside the coil, a magnetic pole is arranged on the outer side of the coil shell, and the magneticpole is fixed on a workpiece shaft. According to the elastic rolling floating support, non-supporting mark grinding is achieved through rolling friction between supporting points and the surface of the workpiece, and follow-up treating matters caused by support marks and even burn are greatly reduced, the influence of the elastic deformation of the workpiece on the grinding efficiency and the quality is reduced, the stress of the elastic supporting points tends to be consistent, and all the points are always in effective supporting states.

Owner:ANHUI SYNCHRONOUS AUTOMATION TECH

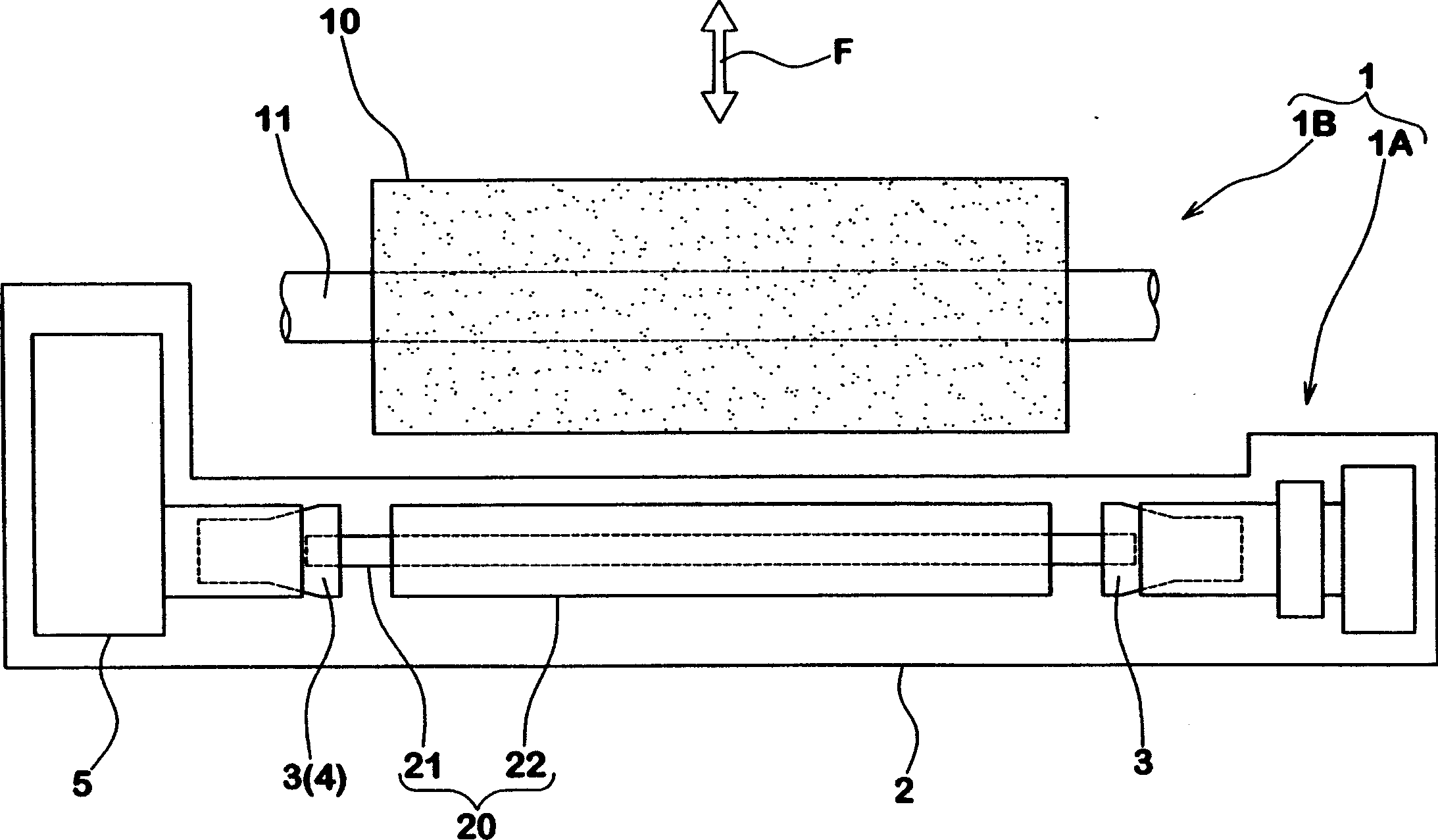

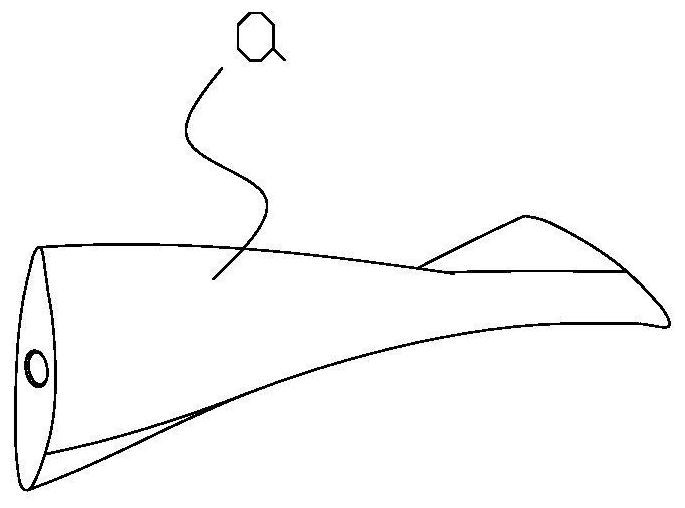

Method for producing rubber drum

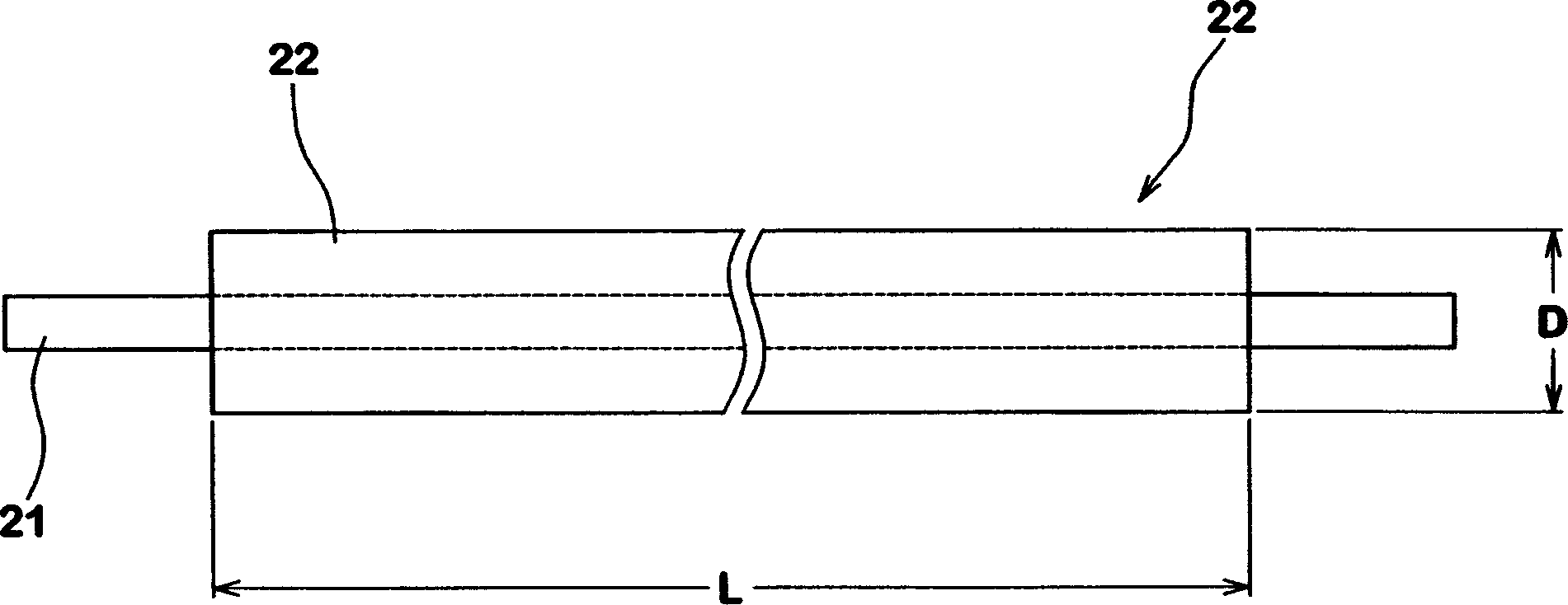

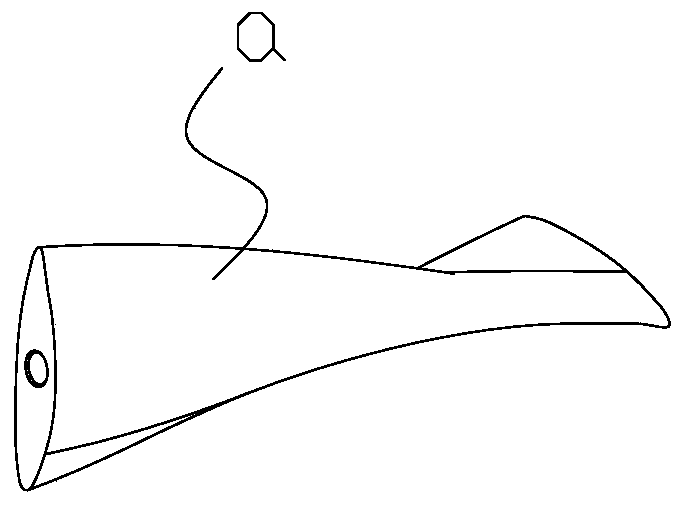

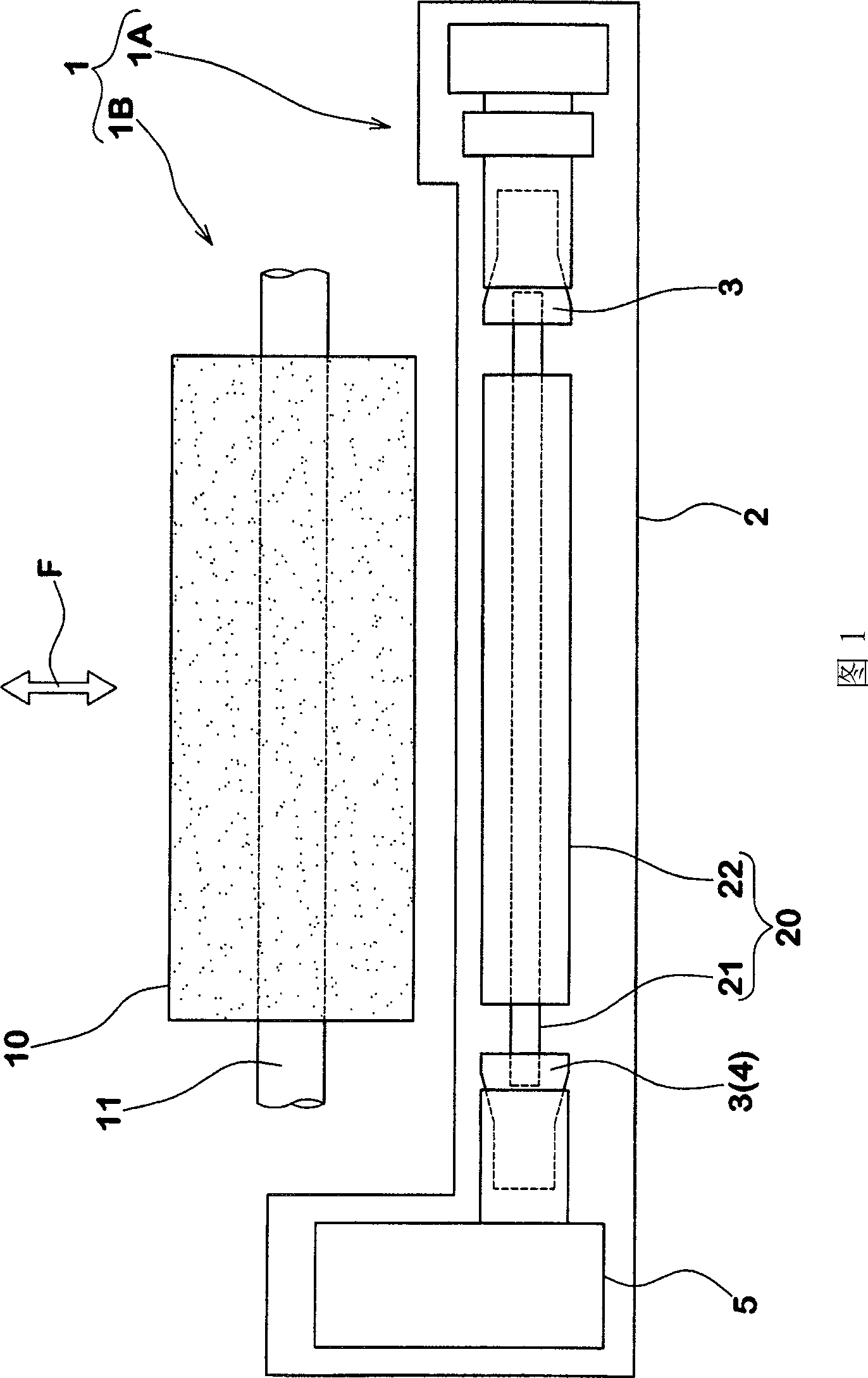

InactiveCN1507981AGood grinding precisionShorten grinding timeRevolution surface grinding machinesBonded abrasive wheelsEngineeringGrinding wheel

To shorten grinding time while exhibiting superior grinding accuracy. A rubber part 22 of a rubber roller is ground by the following grinding steps S of using a grinding wheel 10 wider than the length. The grinding steps S include a preliminary grinding step S1 for grinding by pushing the grinding wheel 10 at a first advance speed V1 of 15 to 25 mm / min toward the axis of the rubber roller 20, an intermediate grinding step S2 for grinding by pushing the grinding wheel at a second advance speed V2 lower than that speed, a finishing grinding step S3 for grinding by pushing the grinding wheel at a third advance speed V3 further lower than that speed and a sparkless grinding step S4 for holding the advance movement in a state of stopping in the final position P of the finishing grinding step S3. (C)2004,JPO&NCIPI.

Owner:SUMITOMO RUBBER IND LTD

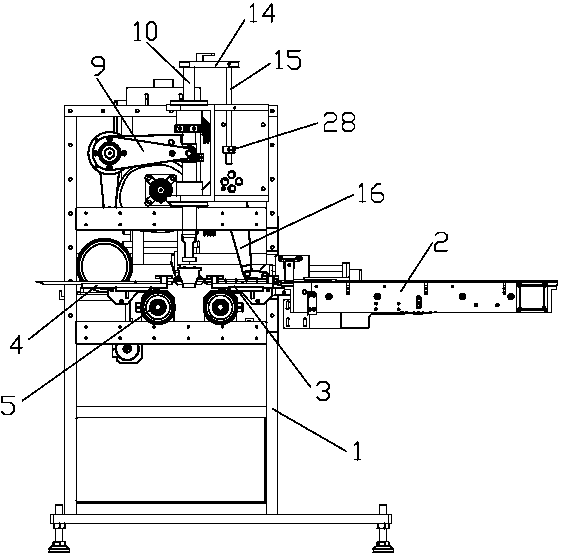

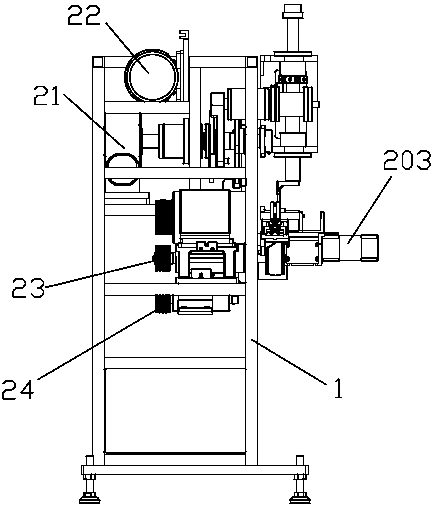

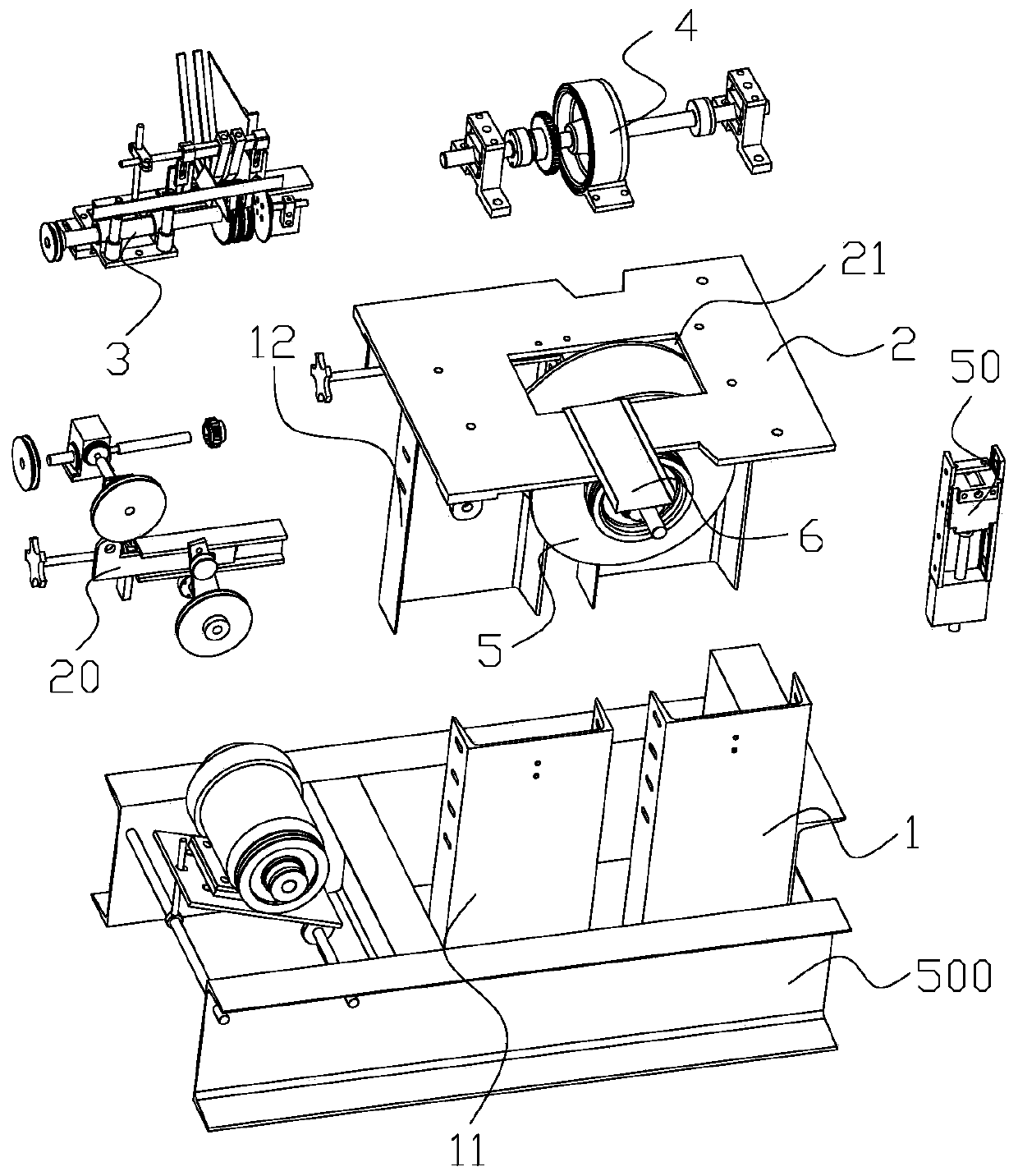

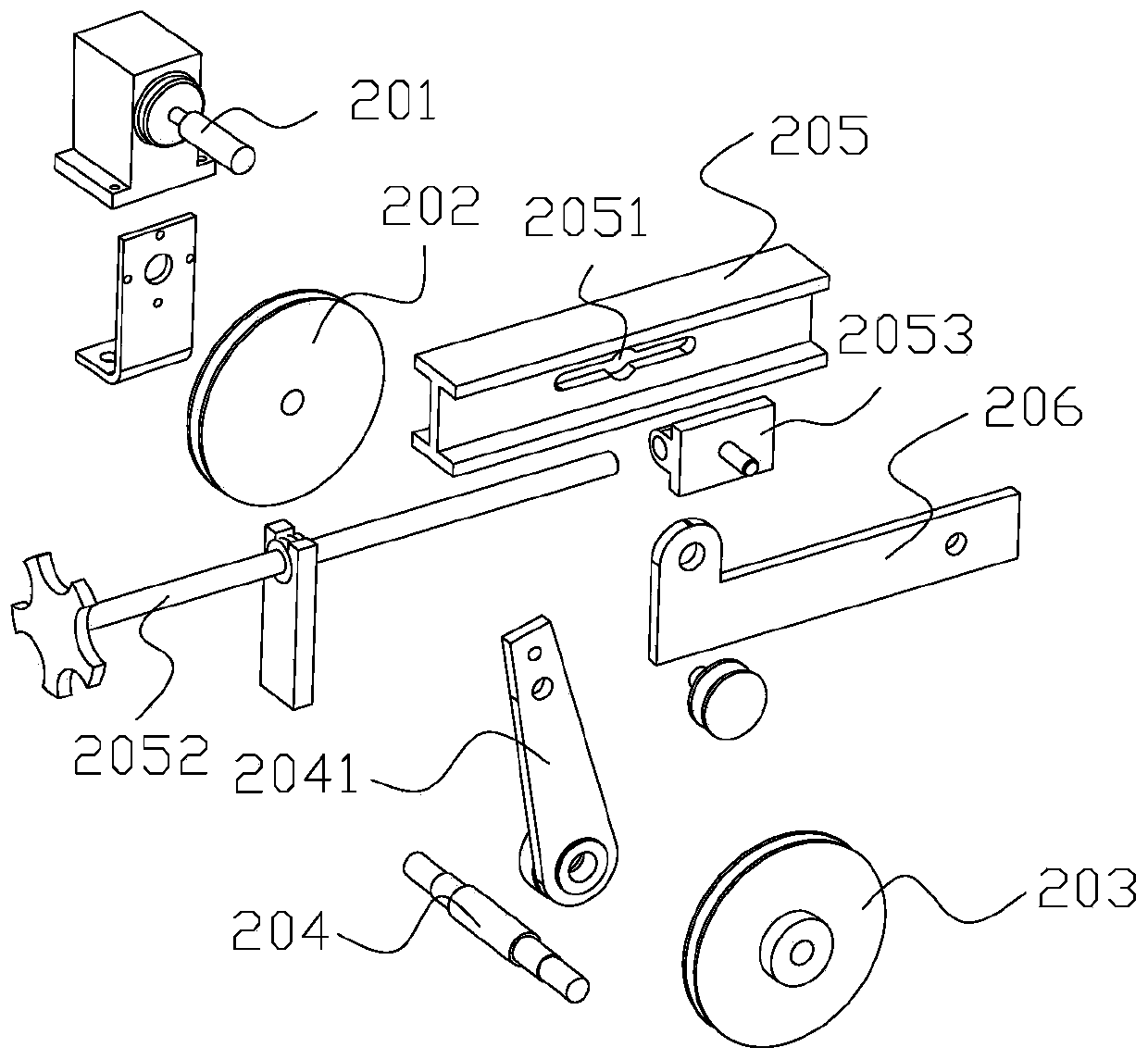

Single-station automatic chamfering machine

ActiveCN108098499AImprove grinding efficiencyGood grinding precisionEdge grinding machinesGrinding feedersWorking environmentEngineering

The invention discloses a single-station automatic chamfering machine, which comprises a support, an electrical equipment control box, a first conveying mechanism, a second conveying mechanism, a third conveying mechanism, a feeding mechanism, a driving mechanism and a grinding mechanism. The feeding mechanism pushes a magnetic shoe on the first conveying mechanism onto a second conveying mechanism so as to push a magnetic shoe on the second conveying mechanism to convey forwards; the grinding mechanism comprises a front grinding wheel and a rear grinding wheel located on the same horizontal line and driven by a motor; the driving mechanism is driven by a first motor to move up and down on a perpendicular bisector of a connecting line of the two grinding wheels; the front grinding wheel and the rear grinding wheel are located under the front end of the second conveying mechanism and under the rear end of the third conveying mechanism; the lower end of the driving mechanism moves between the second conveying mechanism and the third conveying mechanism; and a magnetic shoe channel for the magnetic shoes to pass through is arranged on the lower part of the driving mechanism. The single-station automatic chamfering machine has the beneficial effects of high grinding efficiency on magnetic shoe chamfers, good grinding accuracy and good working environment, and has the advantages ofsimple structure and convenience in operation.

Owner:德昌电机(南京)有限公司

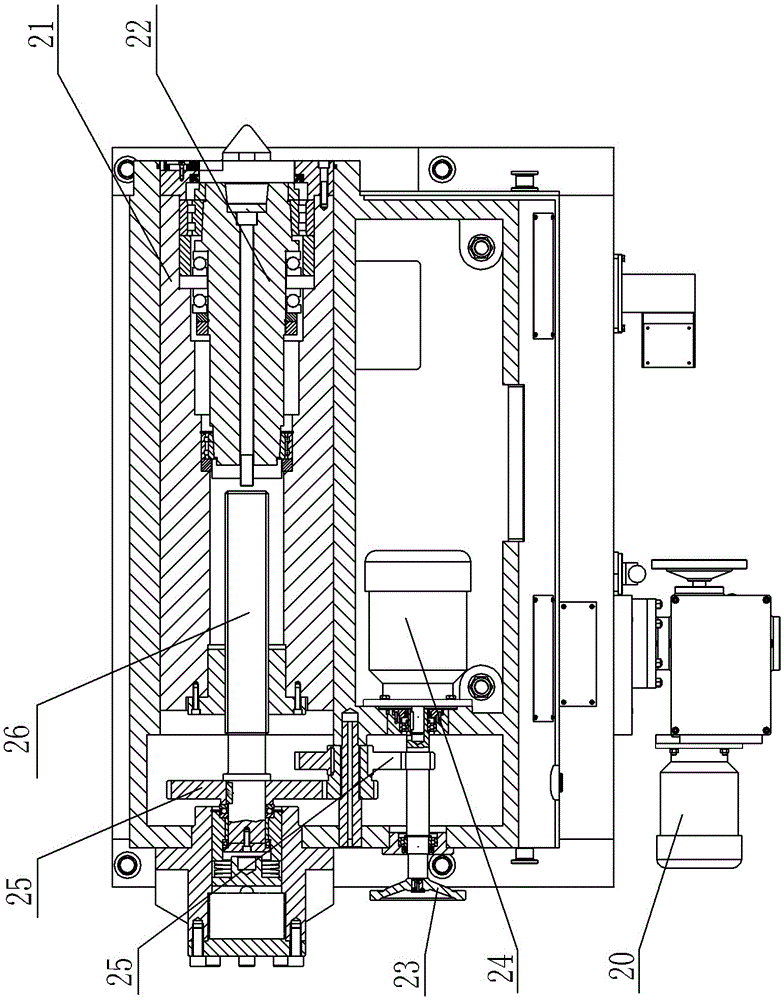

Cutting and grinding device convenient to use

InactiveCN107617941AEasy to installEasy to disassembleEdge grinding machinesGrinding drivesReciprocating motionGear wheel

The invention discloses a cutting and grinding device convenient to use. The cutting and grinding device convenient to use comprises a shell, wherein a first separation chamber, a second separation chamber and a separation plate are arranged in the shell; a reciprocating support, racks, a half tooth gear, a first motor and first fixing shafts are arranged in the first separation chamber, the racksare correspondingly arranged on the two sides of the inner wall of the reciprocating support, the half tooth gear connected with the first motor is arranged in the internal center of the reciprocating support, the half tooth gear is correspondingly meshed with the racks, and the first fixing shafts are arranged at the two ends of the reciprocating support; and a hydraulic device, a hydraulic rod,a first bearing, driving devices, driving mechanisms, driving rotating shafts, polishing brushes, a second motor, a rotating shaft, a rotating sleeve, a fixed base and a receiving plate are arrangedin the second separation chamber, and the hydraulic device is arranged in the center of the top end inside the second separation chamber. The cutting and grinding device convenient to use has the advantages that by arranging the driving mechanisms and the reciprocating support, the polishing brushes swing while rotating, so that the polishing brushes are driven to carry out left-and-right reciprocating motion to polish parts, the grinding and cutting effects of the parts are better, and the working efficiency is improved.

Owner:包晟

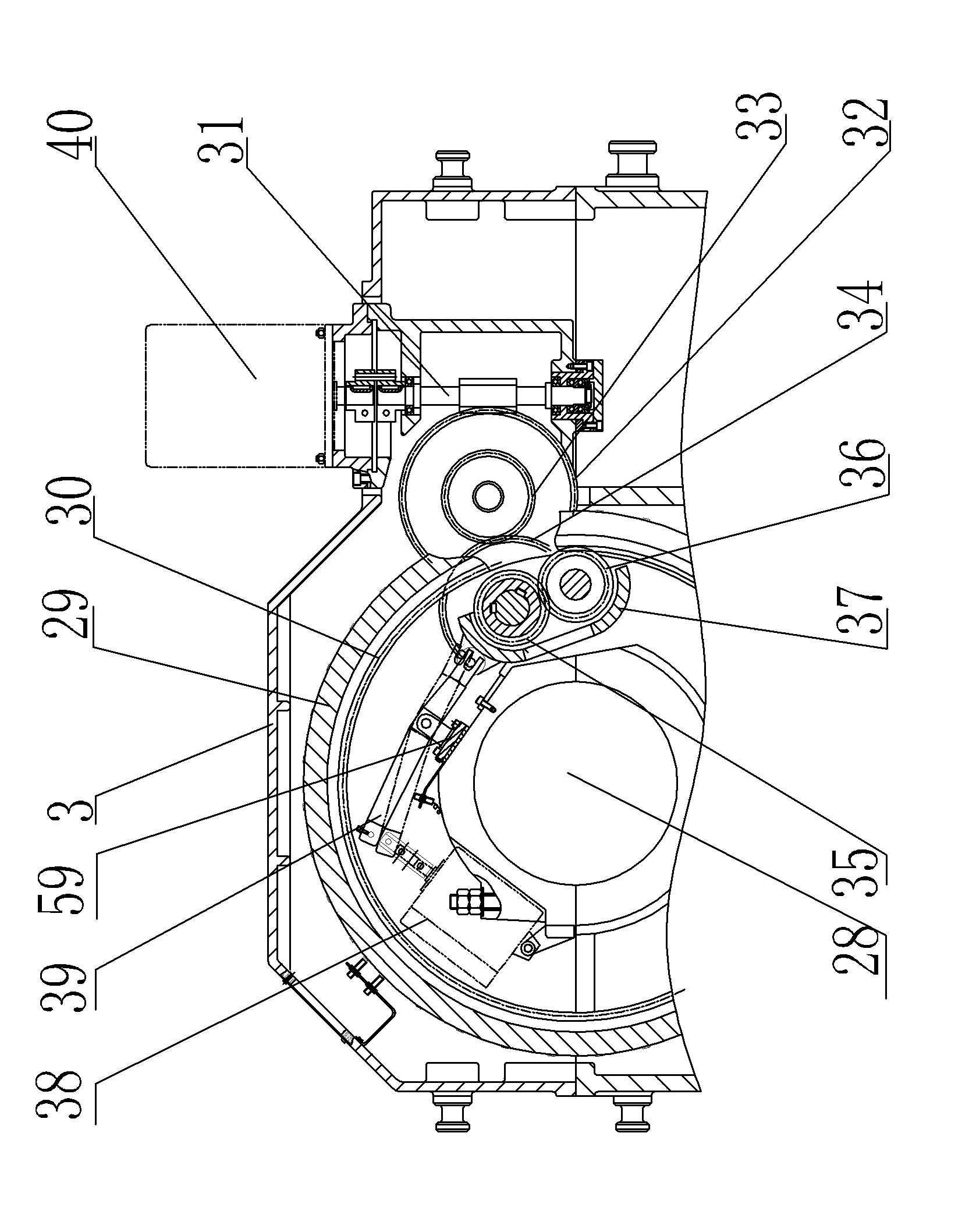

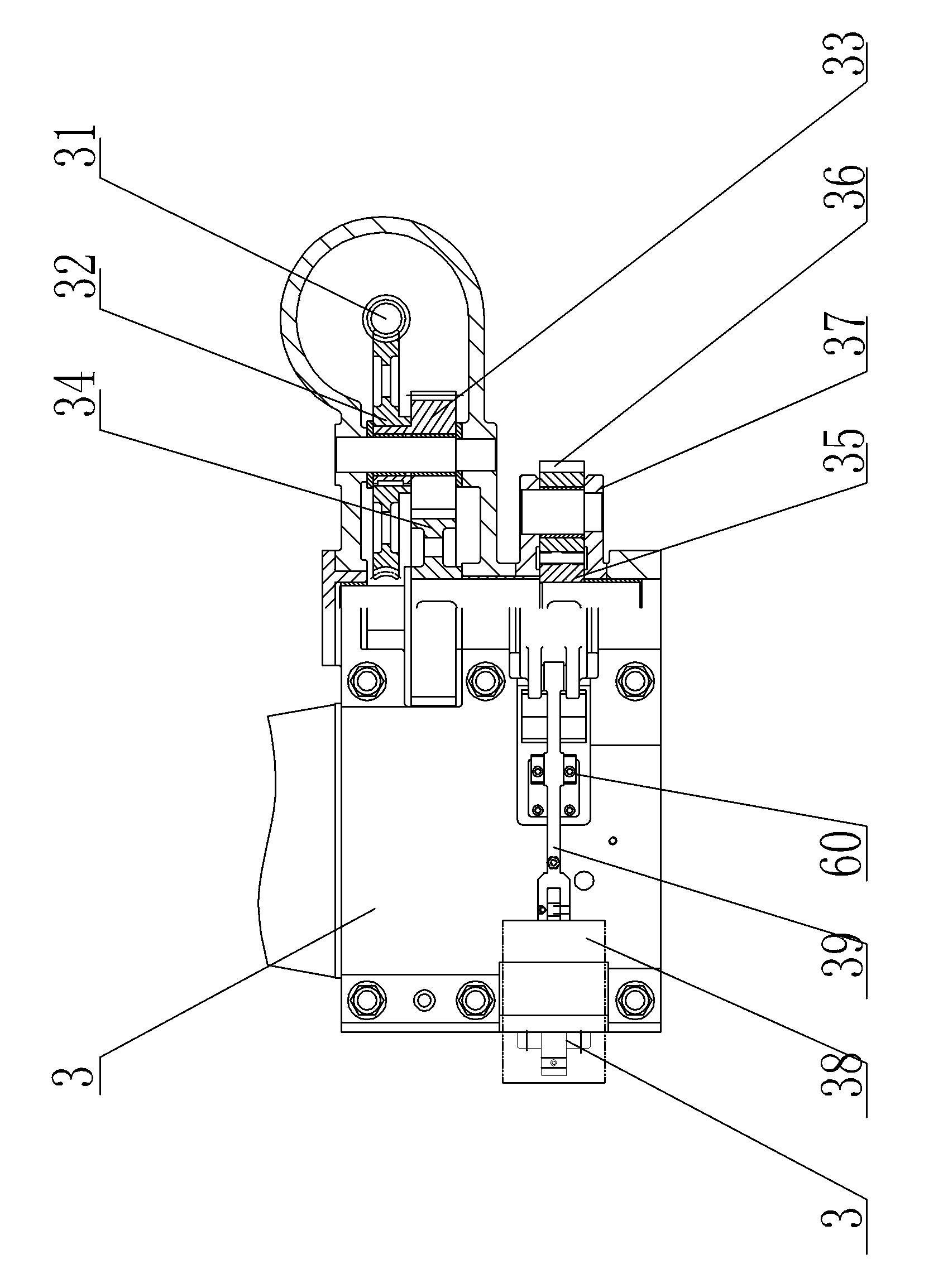

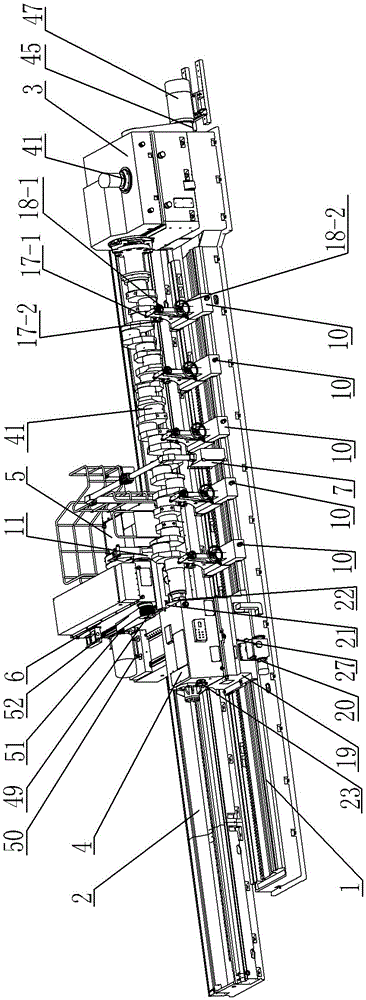

Large-sized numerical control cylindrical grinding machine for crankshaft main journal

ActiveCN103949947AReduce unbalanced centrifugal inertia forceReduce torqueRevolution surface grinding machinesGrinding drivesNumerical controlBall screw

The invention provides a large-sized numerical control cylindrical grinding machine for a crankshaft main journal, which can reduce imbalanced centrifugal inertia force of the revolving crankshaft during grinding, so as to reduce torsion and bending deflection of the crankshaft, meet the roundness processing requirement of the main journal, and realize grinding of a common outer circle of the large-sized crankshaft. The large-sized numerical control cylindrical grinding machine comprises a workpiece lathe bed and a grinding wheel lathe bed, wherein the workpiece lathe body is provided with a headstock and a tailstock; a grinding carriage is arranged on the grinding wheel lathe bed and correspond to the workpiece lathe body; the large-sized numerical control cylindrical grinding machine is characterized by that the grinding carriage is connected with the grinding wheel lathe body through a carriage; the carriage is connected with the grinding wheel lathe body through a guide rail; the grinding carriage is connected with the carriage through a servo motor and a ball screw; a narrow central frame is arranged on the workpiece lathe body; the headstock is fixed at one end of the workpiece lathe body; the tailstock is connected with the workpiece lathe body through the guide rail.

Owner:WUXI SHANGJI AUTOMATION

Grinding machine for electronic part production and using method

InactiveCN112207686AGood grinding effectSolve the inconvenience of grinding precision adjustmentGrinding drivesGrinding machinesElectric machineryGrinding

The invention discloses a grinding machine for electronic part production and a using method thereof. The grinding machine comprises a base, a power device is arranged in the middle of the base, firstgrinding devices and a second grinding device are arranged at one end of the power device, first transmission devices and a second transmission device are fixedly arranged on one side of the base, the first grinding devices are rotatably connected with the first transmission devices, the second grinding device is rotatably connected with the second transmission device, the power device comprisesa motor, bevel gears, a rotating shaft and a limiting hole, the motor is fixedly arranged above the base, the rotating shaft is rotatably connected above the base, and the two bevel gears are fixedlyconnected to the side face of the rotating shaft and the output end of the motor. According to the machine and the method, the problems that a traditional grinding machine is inconvenient in grindingprecision adjustment, has limitation and is narrow in application range are solved; and the problems that when the traditional grinding machine grinds an electronic part with high surface roughness, the grinding efficiency is low, and the grinding effect is poor are solved.

Owner:南京阿兹曼电子科技有限公司

High-performance ceramic combination grinding wheel

InactiveCN105538178AImprove grinding efficiencySmall grinding forceAbrasion apparatusPotassiumSilicon dioxide

The invention discloses a high-performance ceramic combination grinding wheel which is prepared by mixing a ceramic binder and modified diamond, wherein the ceramic binder is prepared from the following raw materials in parts by weight: 10 to 15 parts of silicon dioxide, 2 to 5 parts of aluminum oxide, 1 to 4 parts of anhydrous sodium carbonate, 0.5 to 5 parts of boric acid, 2 to 6 parts of potassium oxide, 5 to 10 parts of calcium carbonate, 4 to 8 parts of anhydrous lithium carbonate, 1 to 4 parts of oxidized polyethylene wax and 2 to 6 parts of titanium oxide; the modified diamond is prepared from the following raw materials in parts by weight: 30 to 45 parts of a common diamond abrasive material, 5 to 10 parts of a black corundum abrasive material, 1 to 3 parts of chisel tool steel powder, 3 to 6 parts of borax, 2 to 6 parts of nano-copper powder, 4 to 8 parts of absolute ethyl alcohol, 6 to 9 parts of hydrochloric acid and 1 to 3 parts of butyl titanate. Due to the mode, the high-performance ceramic combination grinding wheel disclosed by the invention has the advantages of low grinding power, high grinding efficiency, good grinding precision, long service life and easiness in modification, and can be widely applied to molding grinding of engineering materials.

Owner:CHANGSHU SHANG GAO MACHINERY

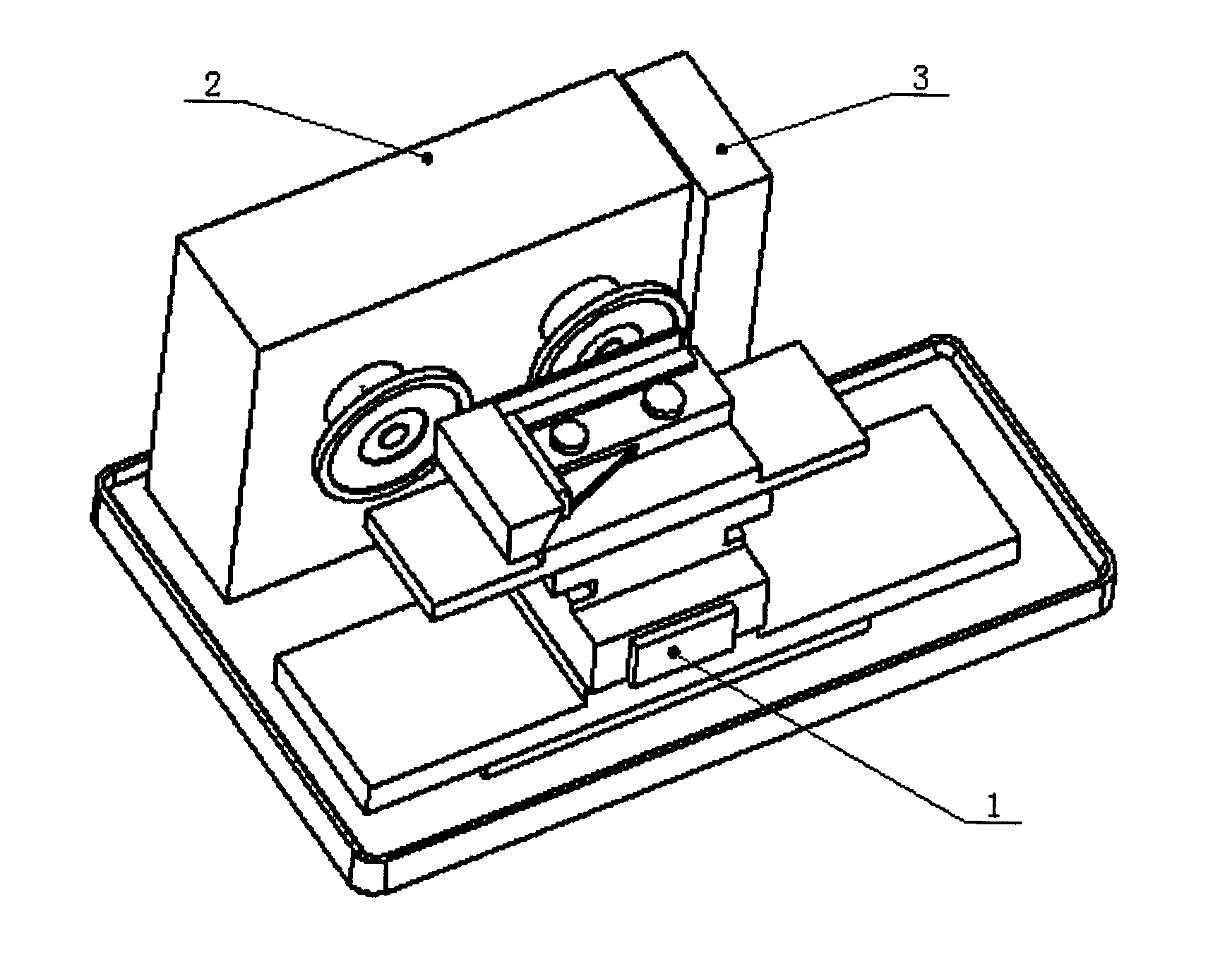

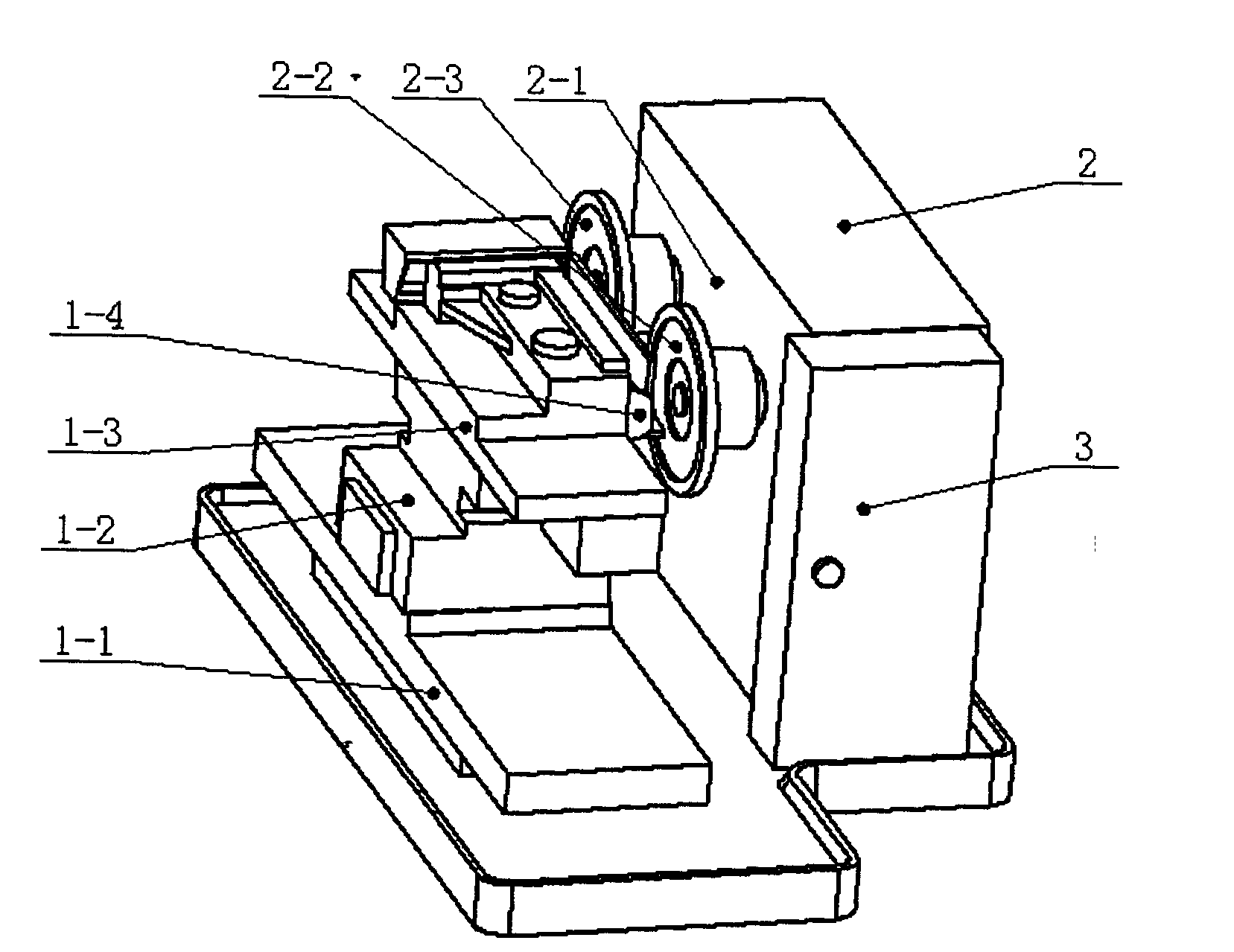

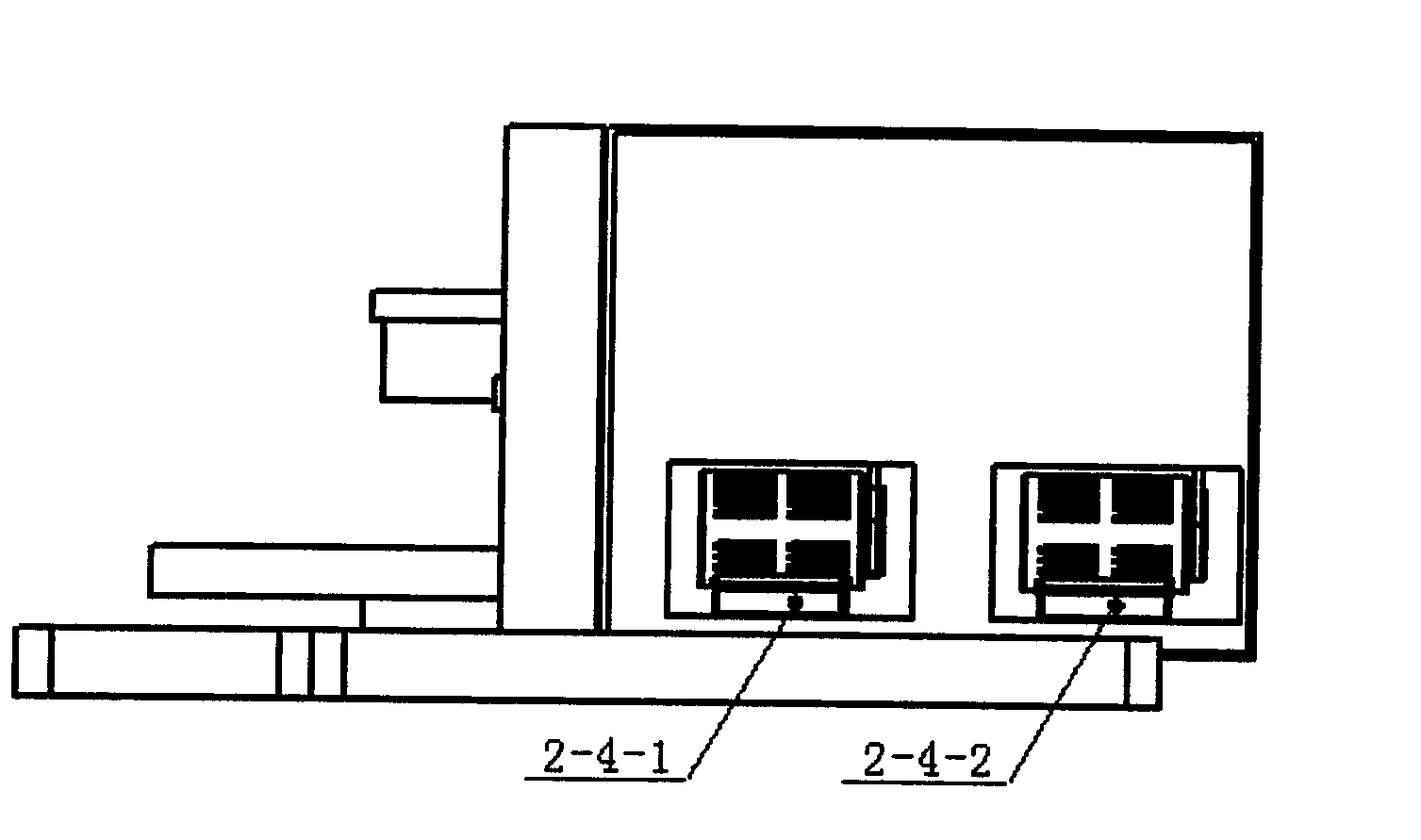

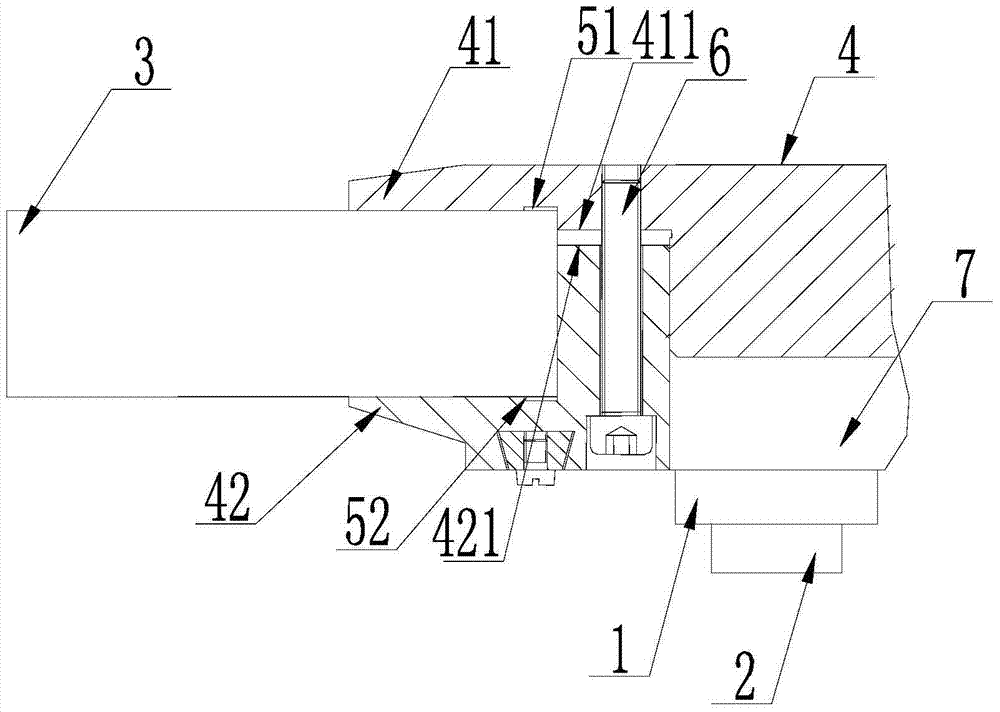

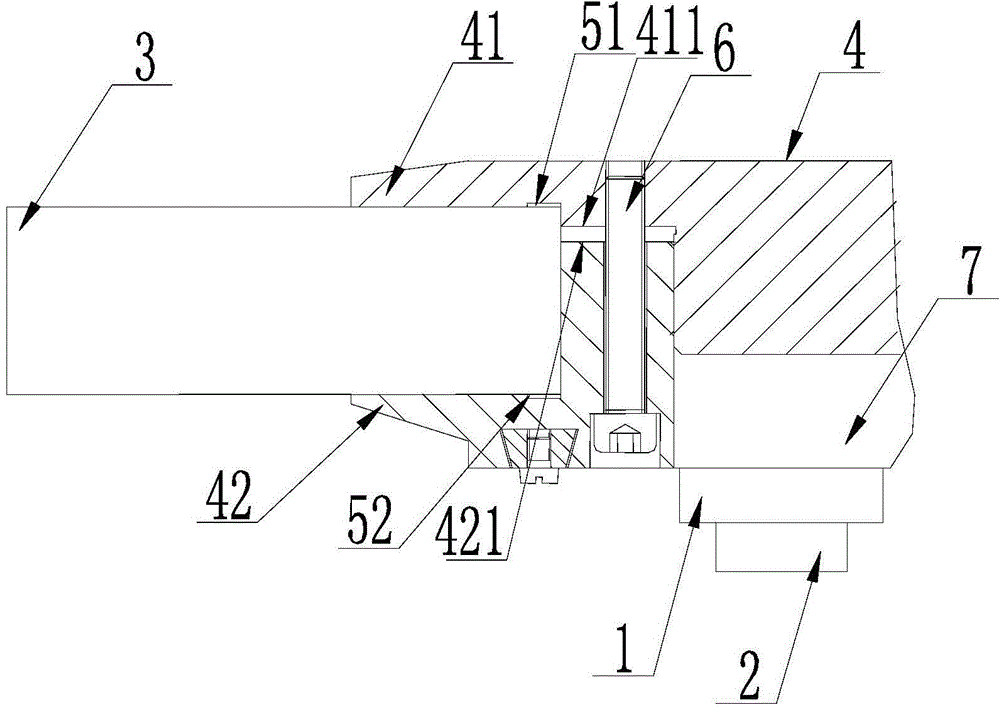

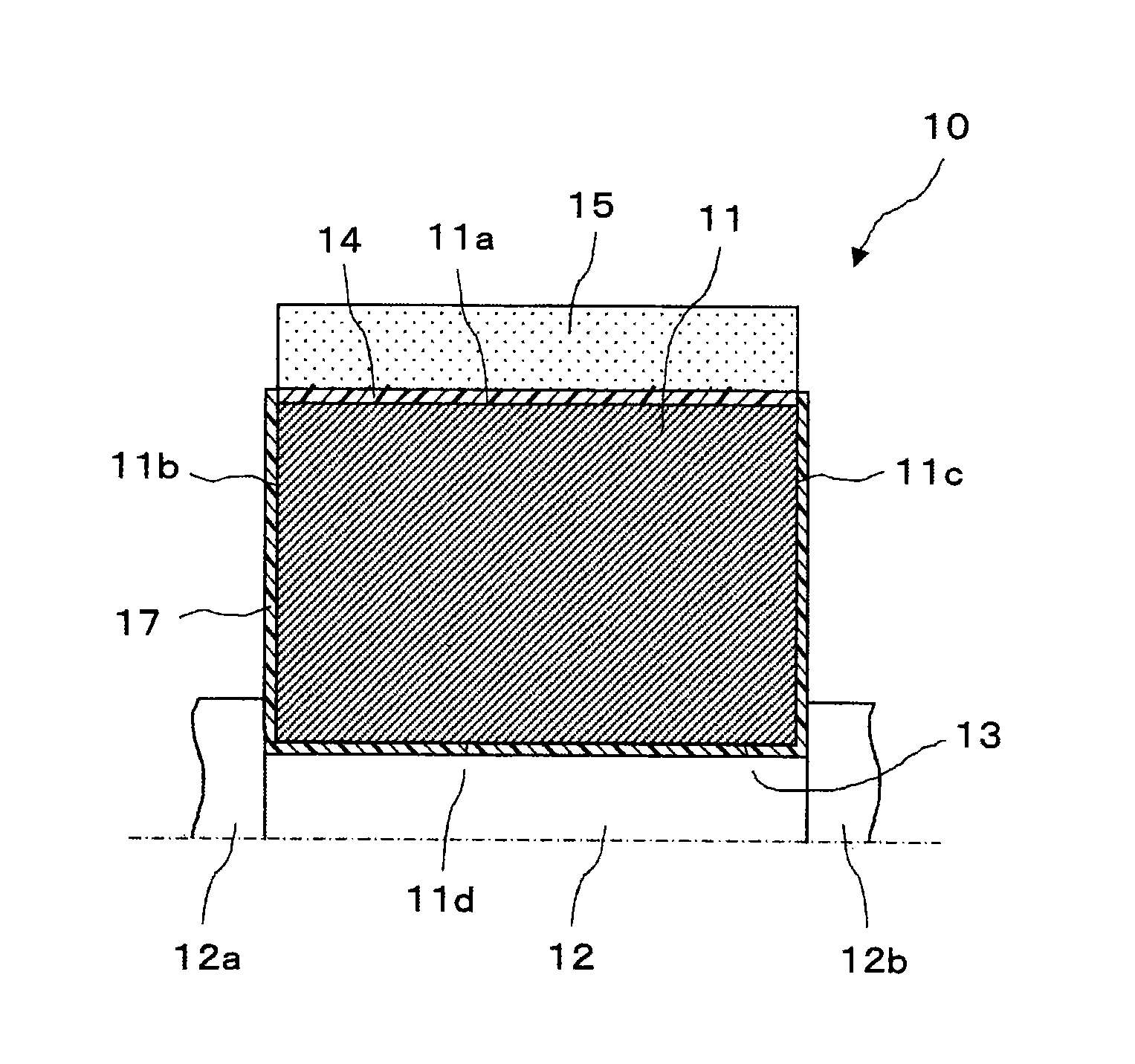

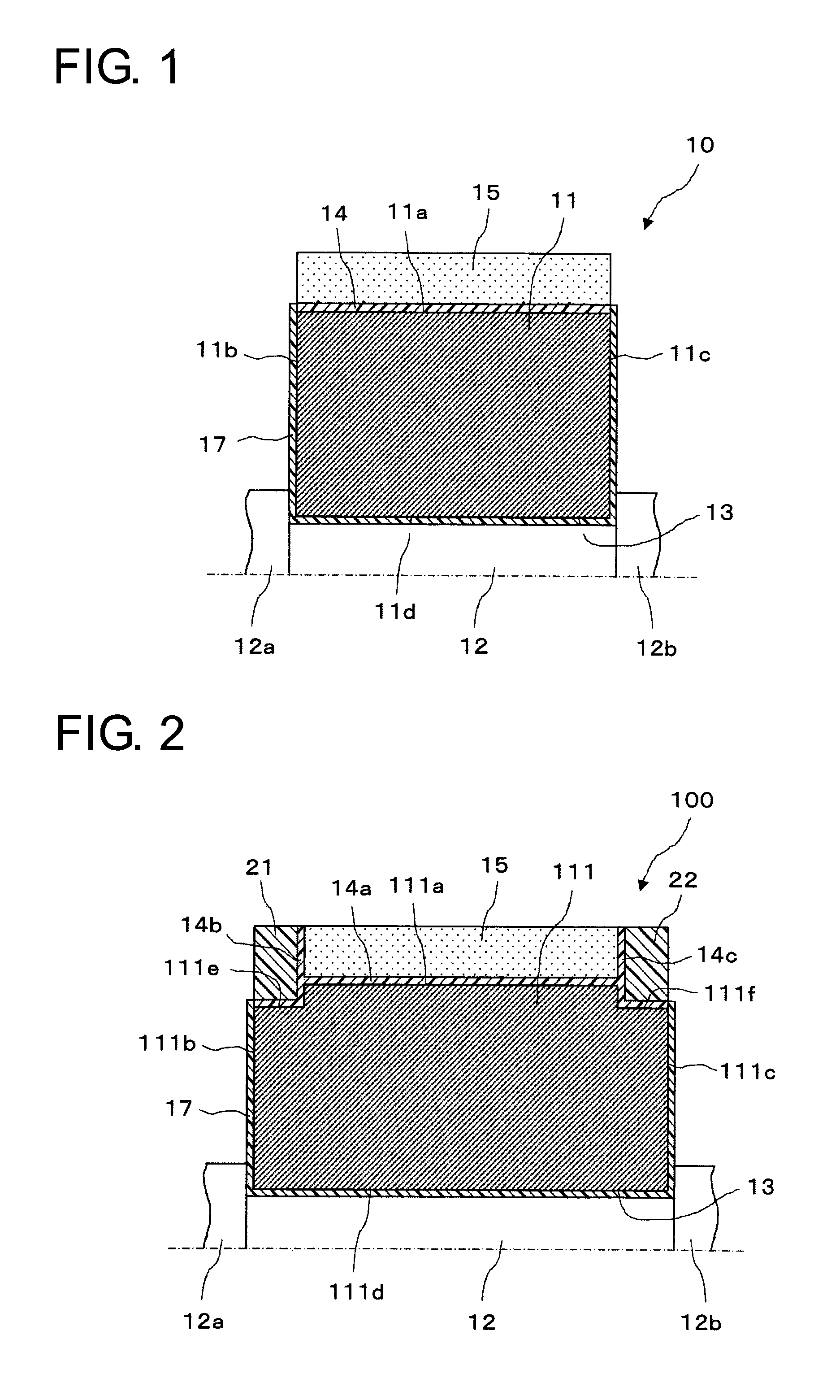

Numerical control grinder with double grinding wheels

InactiveCN102848291AGood grinding precisionImprove machining accuracyGrinding machinesGrinding work supportsNumerical controlElectric machinery

The invention relates to a numerical control grinder with double grinding wheels. The numerical control grinder comprises a grinder body foundation, a grinding wheel mechanism and a numerical control device, and is characterized in that a motor and a main grinding wheel device as well as a motor and an auxiliary grinding wheel device are respectively arranged in a fixed seat of the grinding wheel mechanism, a control circuit of the grinding wheel mechanism is connected with the numerical control device, the grinder body foundation is sequentially provided with an A-axis total range, a Z-axis total range, an X-axis total range and a Y-axis total range, and the control circuits of servo motors of an A axis, a Z axis and an X axis and a moment servo motor of a Y axis are all connected with the numerical control device. Compared with the prior art, the numerical control grinder has the advantages and the beneficial effects that the grinding of a plurality of slopes or concave cambered surfaces can be completed through the technology of one time of clamping and two times or many times of grinding, the same standard is used for two times or many times of grinding, the optimum grinding precision is achieved, the processing precision and the work efficiency are improved, and the processing cost is reduced.

Owner:梁刚

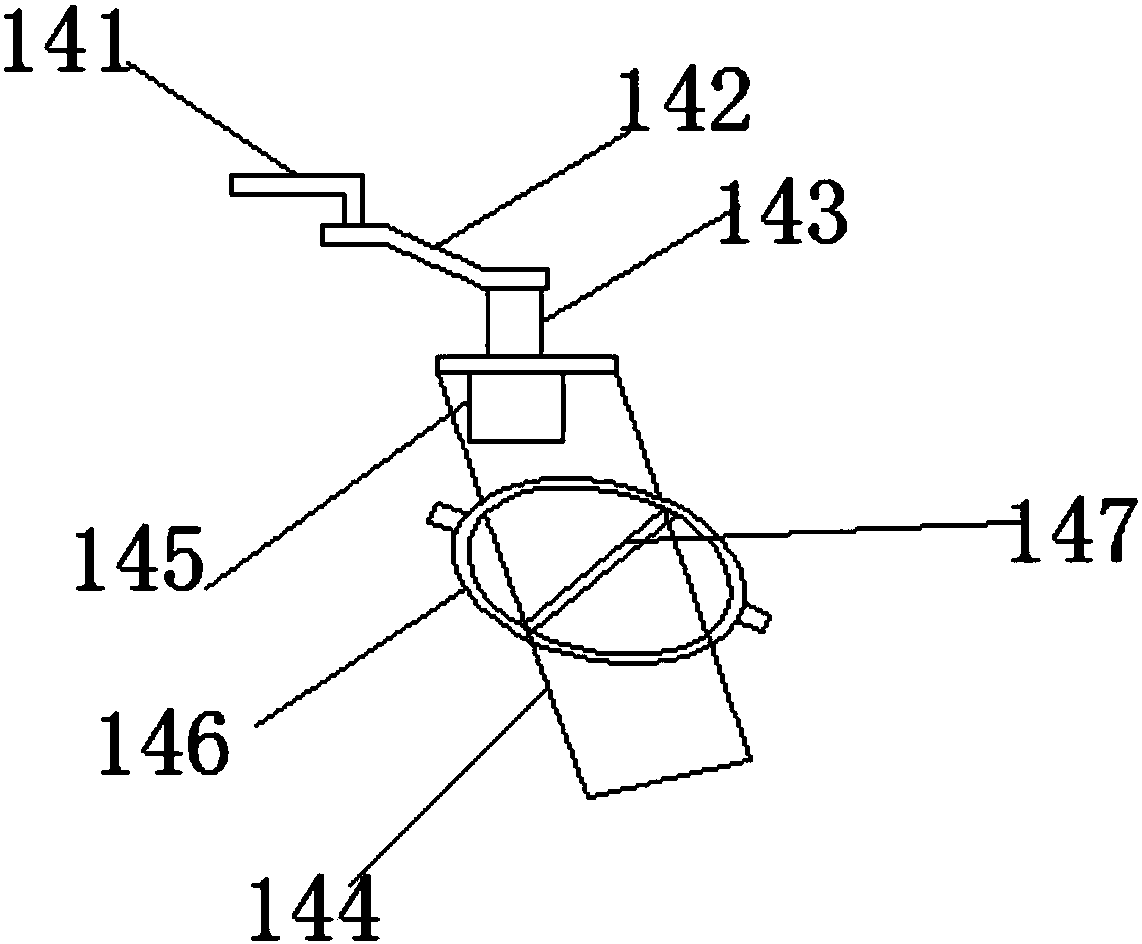

A chamfering tool for research and development of optical parts

ActiveCN110539226BAvoid the trouble of returning to the factory for chamferingControl grinding speedEdge grinding machinesGrinding drivesCouplingElectric machinery

The invention discloses a chamfering tool for research and development of optical parts, which comprises a main frame body, a motor, a support rod, a lower tray, a lens, an upper tray, a final shaft, a threaded flange, a grinding device and a shaft coupling. There are two sets of bottom grooves on the horizontal part of the lower end of the frame body, frame holes, motor holes and motor shaft holes are opened on the horizontal part of the middle part of the main frame body, and two groups of horizontal grooves bent on the side wall of the main frame body There are eccentric shaft holes on some parts, frame holes, flange holes and flange threaded holes are opened on the horizontal surface of the upper end of the main frame body, and the motor passes through the motor hole through the screw to enter the inside of the threaded hole above it and The main frame body is fixed, the output shaft of the motor passes through the motor shaft hole of the main frame body, a coupling is fixed on the output shaft of the motor through screws, and the upper end of the coupling is sleeved on the lower side of the lower tray on the axial structure. The chamfering cutter used for research and development of optical parts can quickly chamfer optical lenses and is suitable for general promotion and use.

Owner:江苏聚冠新材料科技有限公司

High concentration silica slurry

InactiveCN1711216AReduce viscosityGrinding speed is fastPigmenting treatmentOther chemical processesHigh concentrationPotassium

A kind of high-concentration silica mud, it is characterized in that: the silica concentration that forms by dispersing silica powder in the solvent is more than 50wt%, and viscosity is below 1000mPa·s, wherein said silica powder obtains the average particle diameter ( The ratio (DL / DT) of DL) to the average particle diameter (DT) obtained by TEM imaging is 1.3 or less, and the average primary particle diameter is 0.08 μm to 0.8 μm. It is preferable to use high-concentration silica mud with a silica concentration of 70 wt% to 80 wt% and a viscosity of 800mPa·s or less during mud preparation. The silica mud uses silica powder with a specific impurity content. The impurities of sodium and potassium in the silica powder The concentrations are all 1.0 ppm or less, the aluminum content is 1.0 ppm or less, and the respective contents of sulfur, nickel, chromium and iron are all 0.5 ppm or less.

Owner:NIPPON AEROSIL

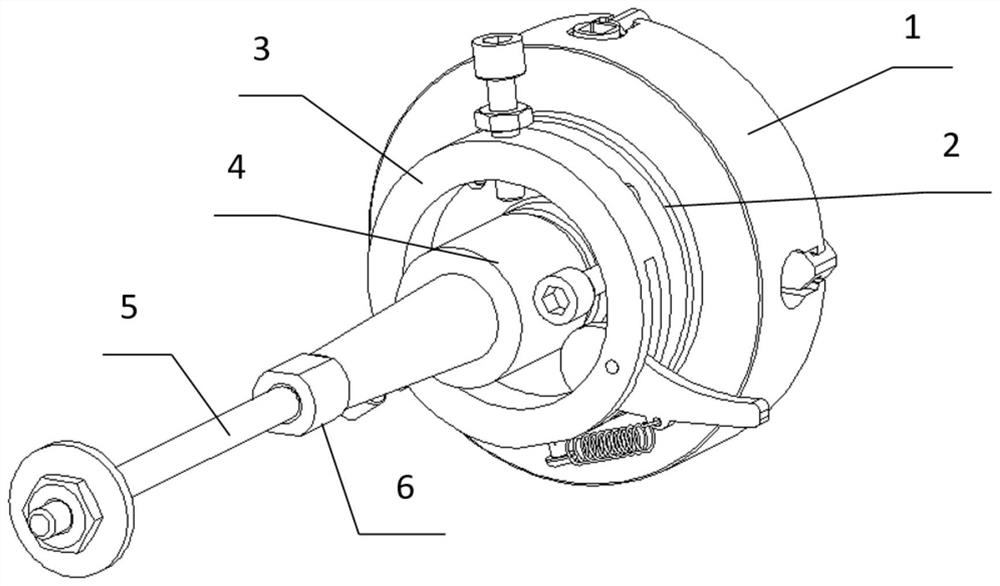

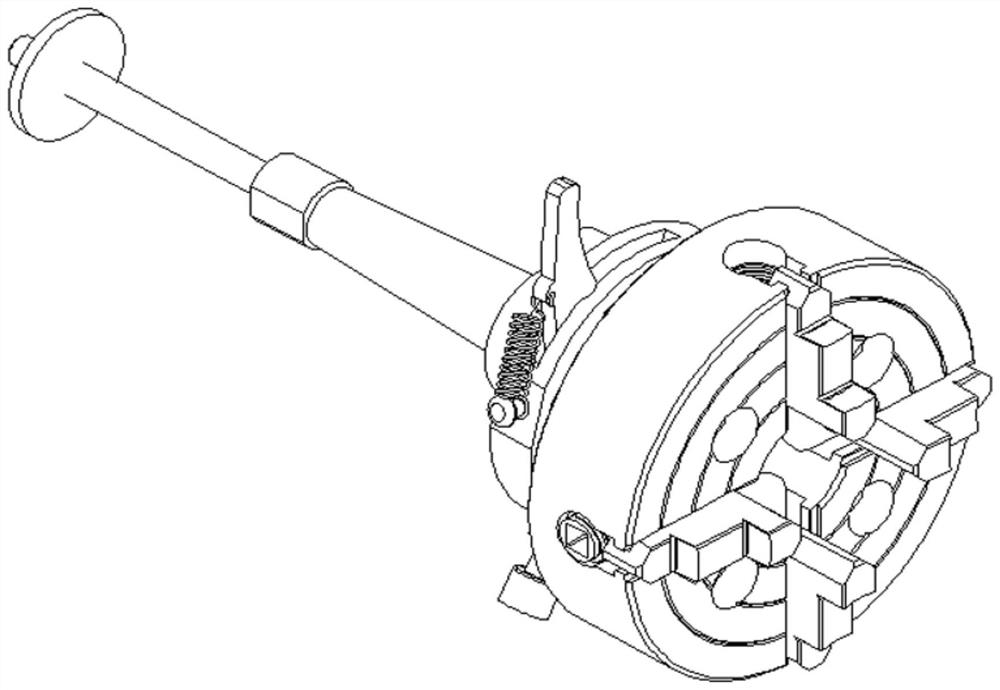

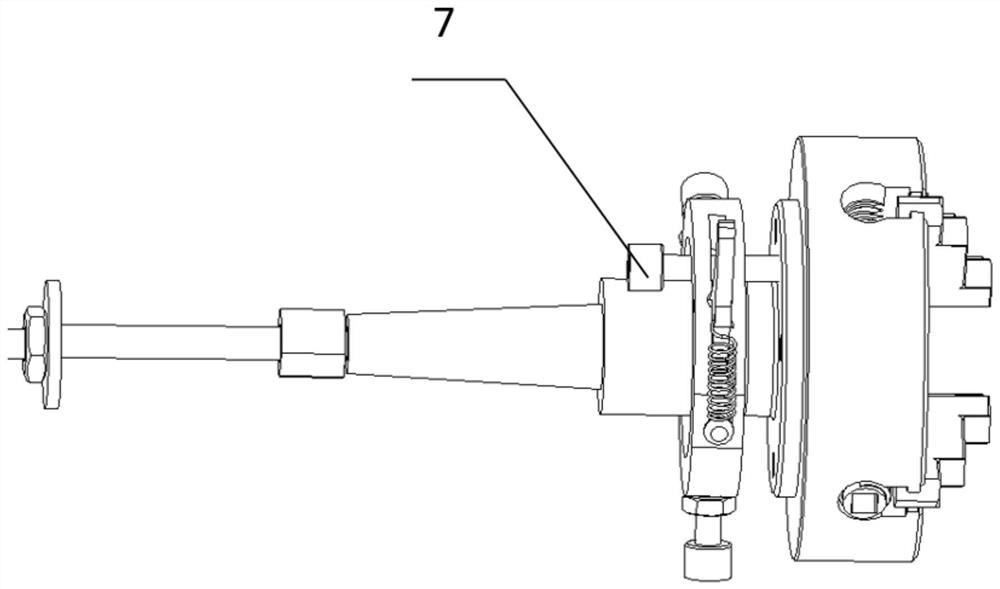

Clamping device capable of being used for improving grinding precision of shaft parts

PendingCN112589674AImprove grinding accuracyRealize clampingGrinding work supportsAviationMechanical engineering

The invention belongs to the technical field of aviation equipment manufacturing, and particularly relates to a clamping device capable of being used for improving the grinding precision of shaft parts. The clamping device comprises a four-jaw chuck, a flange plate, a locking device, a live center, a tensioning pull rod, an adapter and a locking screw. According to the clamping device capable of being used for improving the grinding precision of the shaft parts, an operator can very easily clamp, align and repair the shaft parts, the grinding precision of the shaft parts is greatly improved, and the rejection rate of the parts is obviously reduced.

Owner:大连长丰实业总公司

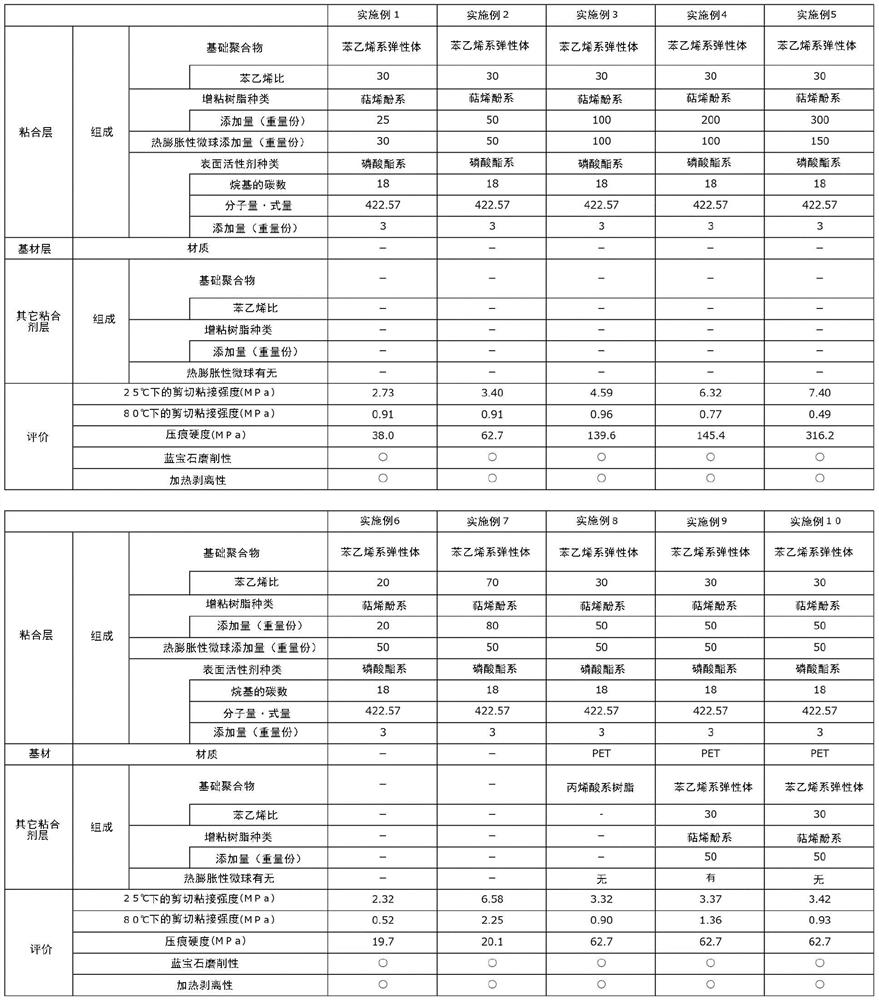

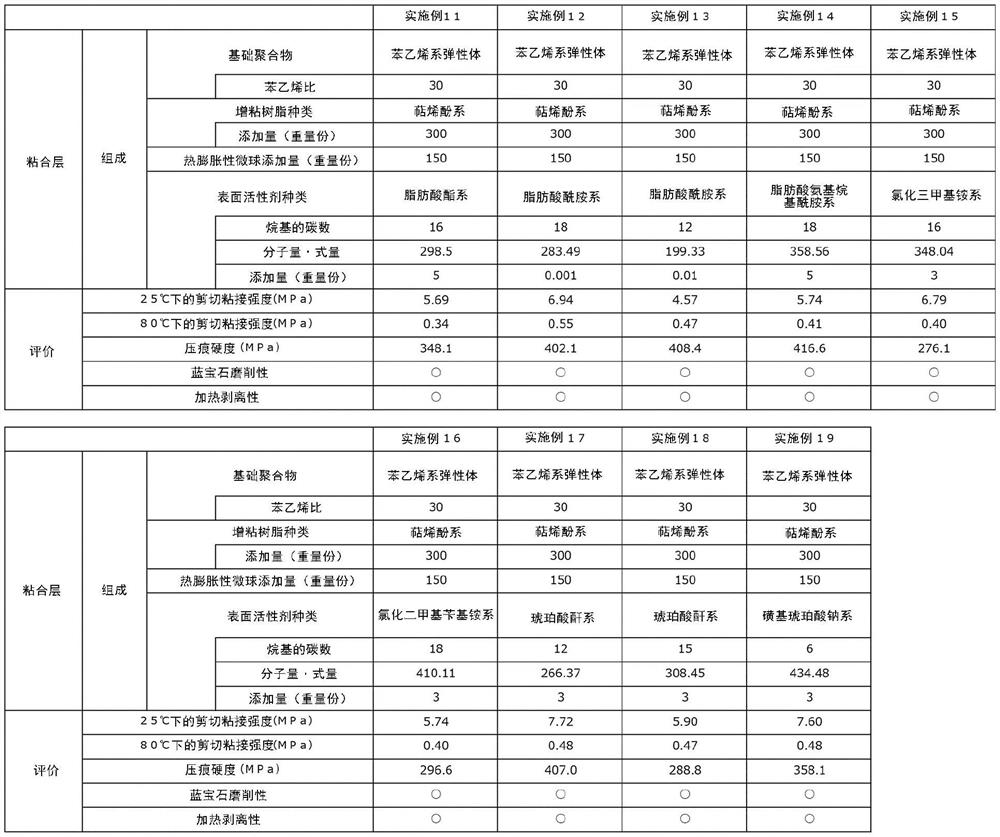

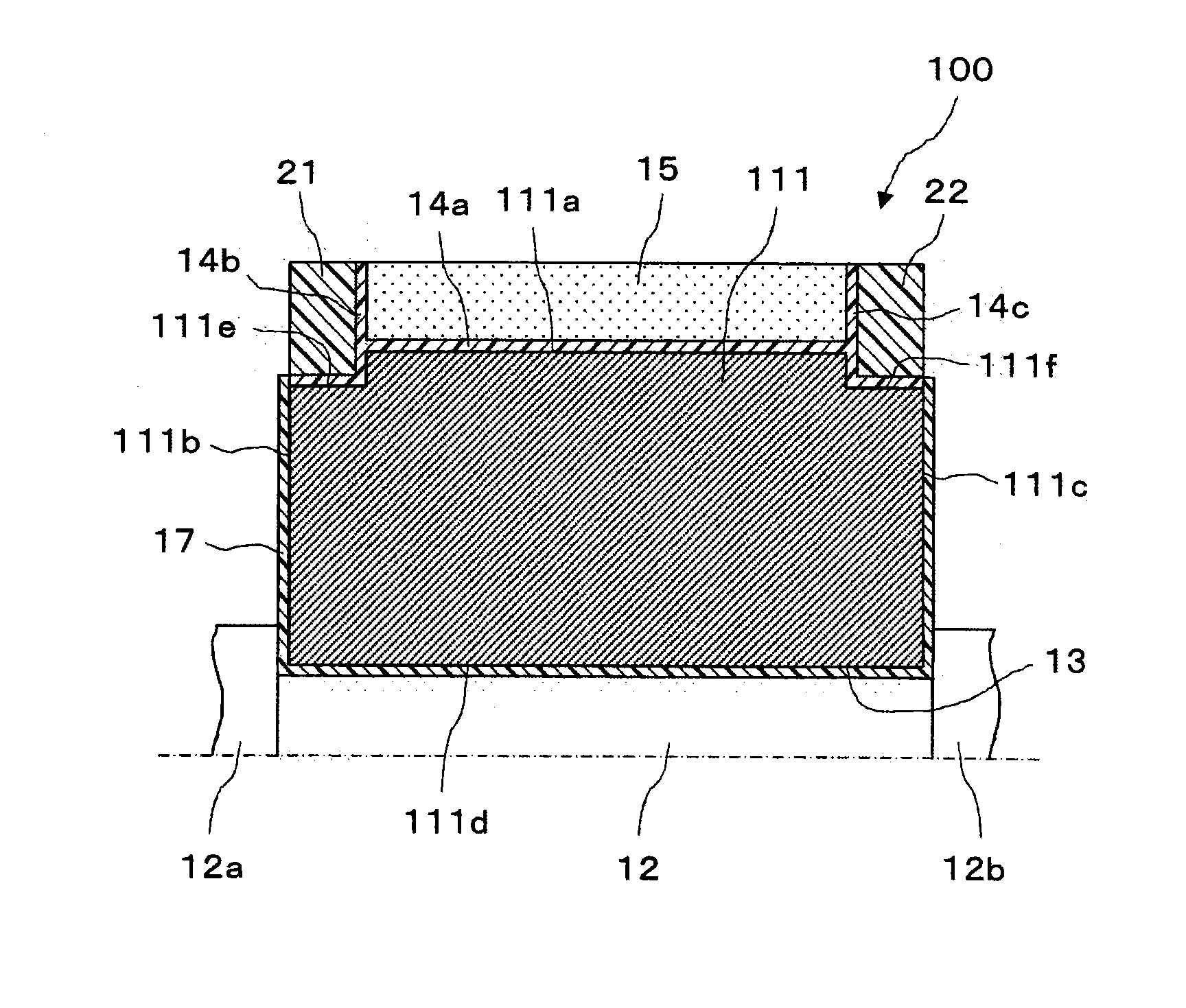

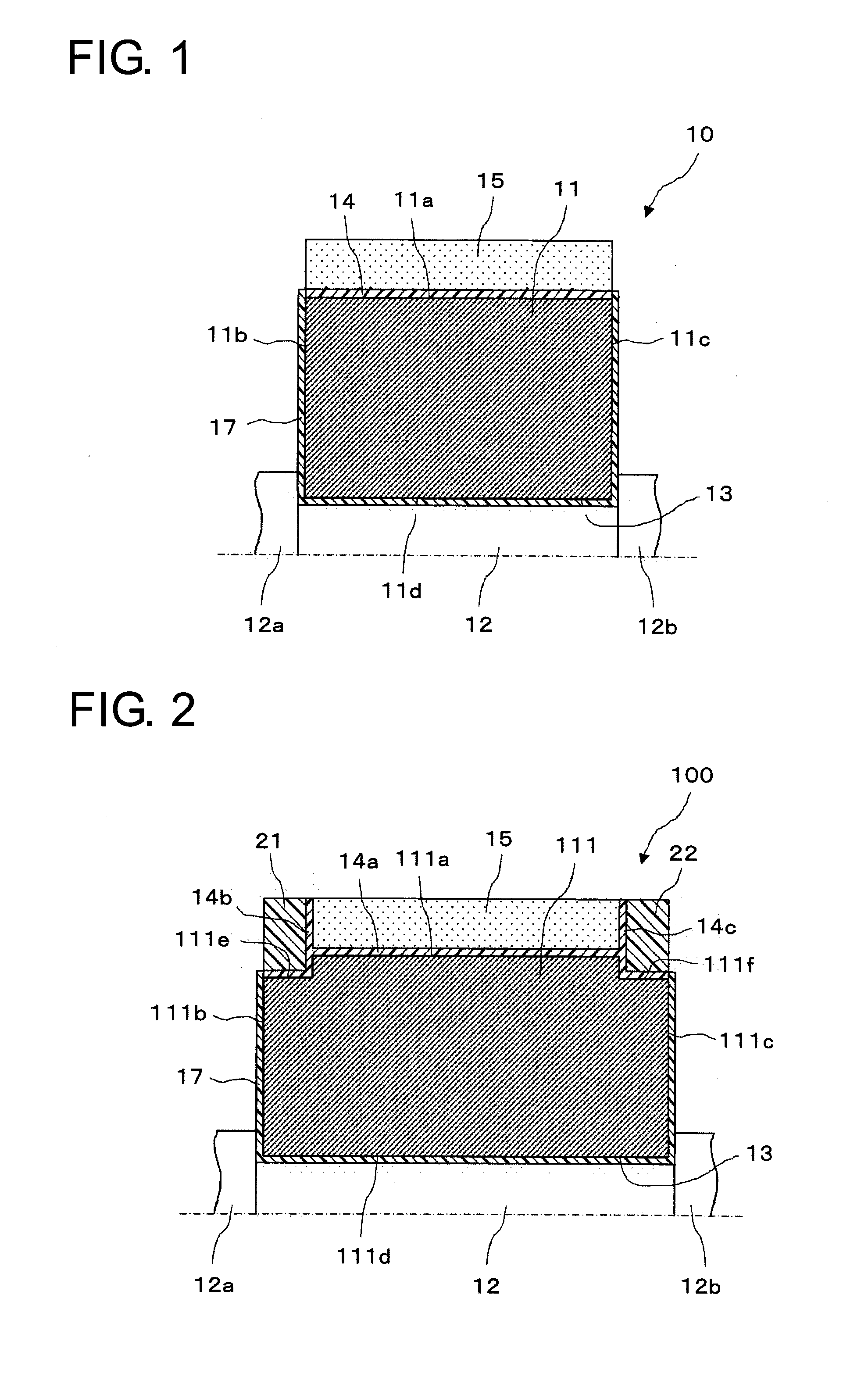

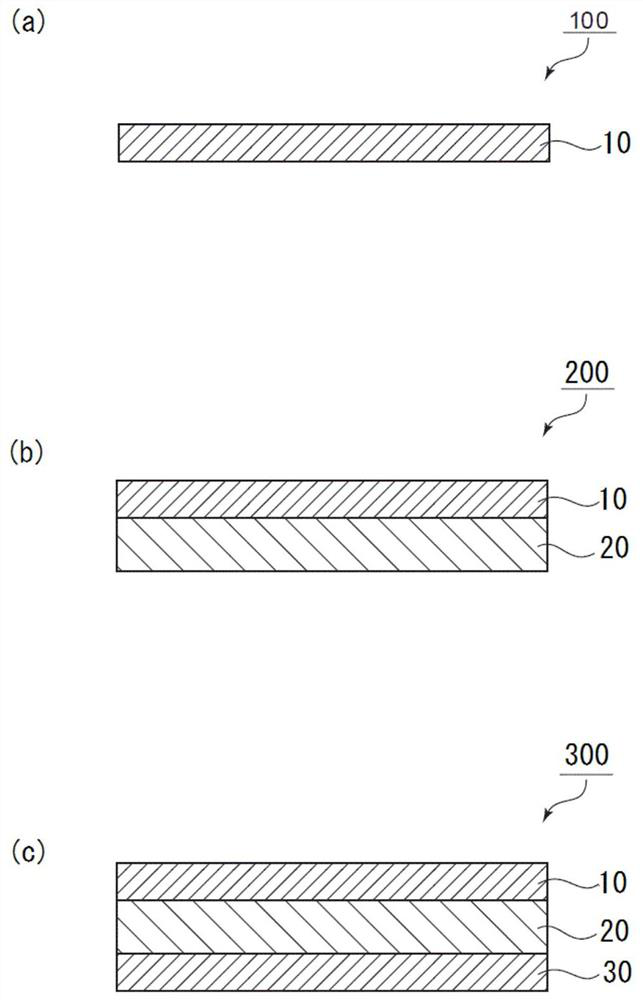

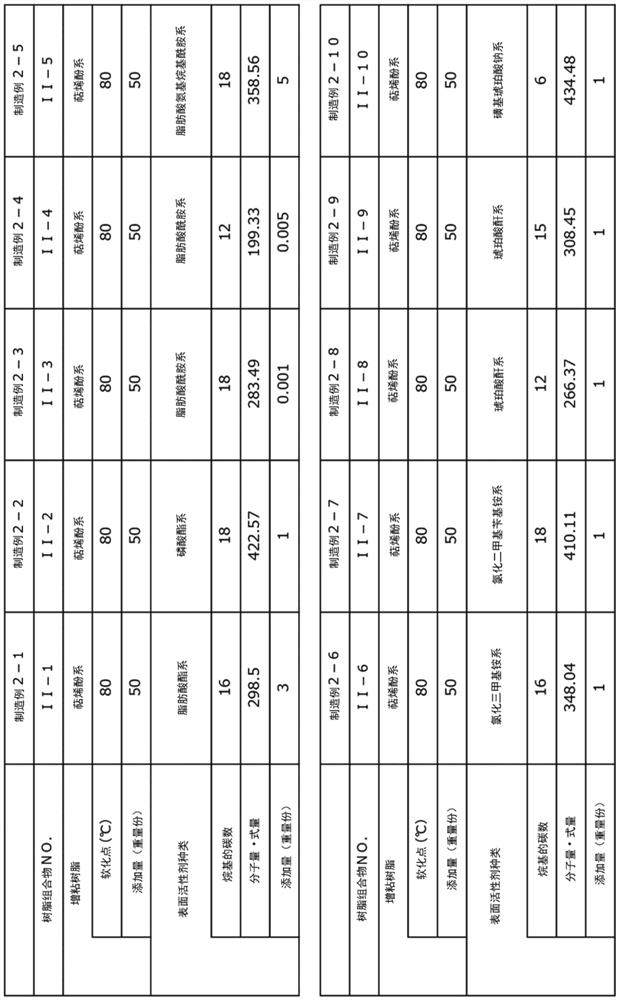

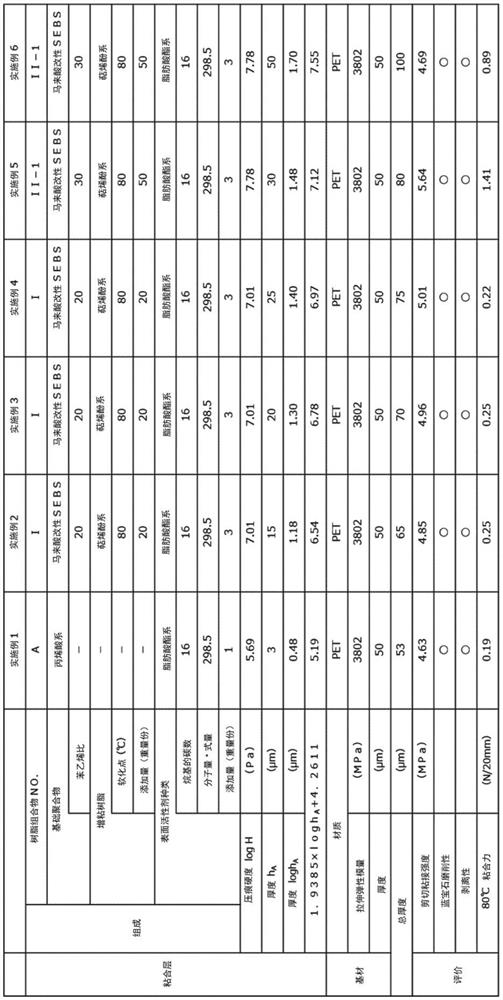

Adhesive sheet

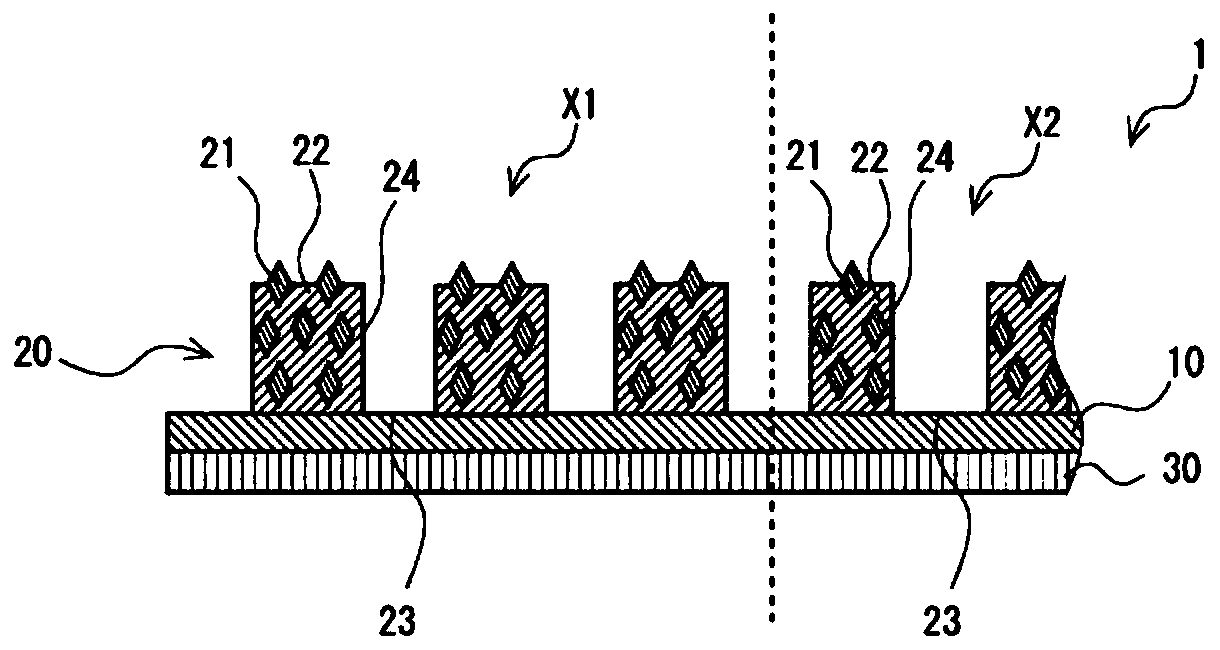

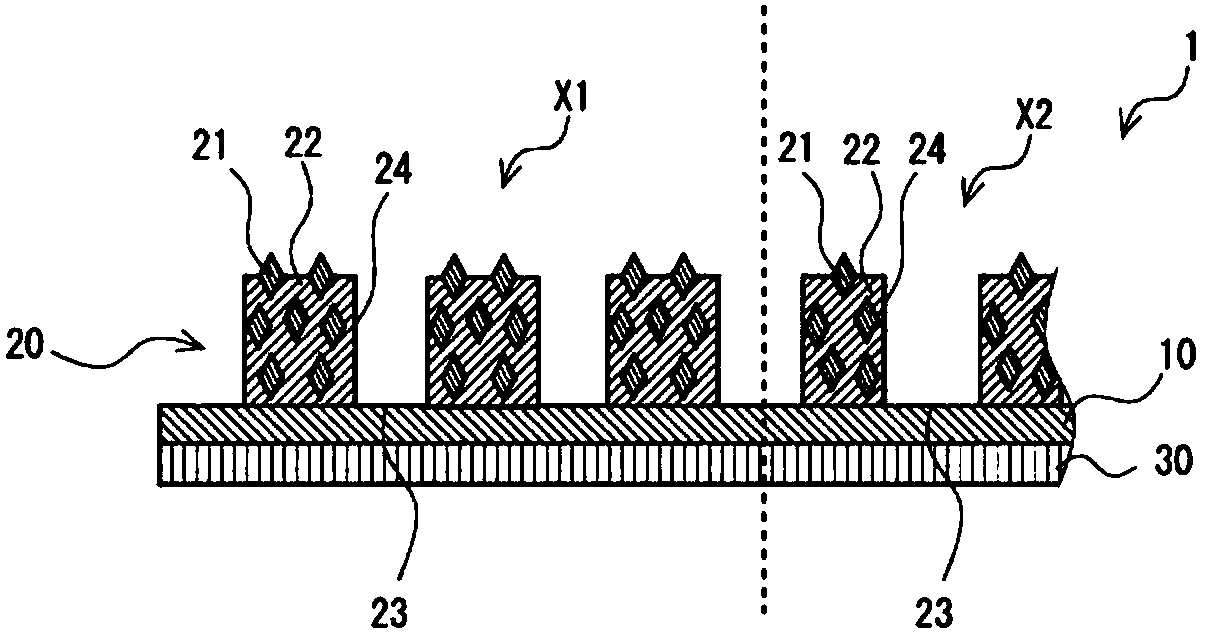

ActiveCN112639040AReduce pollutionGood grinding precisionNon-macromolecular adhesive additivesSolid-state devicesPolymer scienceFoaming agent

Provided is an adhesive sheet that can be used to grind a hard and brittle substrate during back-grinding of the hard and brittle substrate and that makes it possible to reduce pollution and achieve excellent grinding precision, productivity, and fixation. This adhesive sheet comprises an adhesive layer. The adhesive layer includes: an adhesive that includes a base polymer; and a foaming agent that has a foaming temperature of at least 90 DEG C. The shear adhesive strength of the adhesive sheet when a silicon chip has been stuck to an adhesive surface thereof is at least 1.0 MPa at 25 DEG C and at least 0.2 MPa at 80 DEG C.

Owner:NITTO DENKO CORP

Abrasive grinding wheel

ActiveUS20150258661A1Improve balanceGood grinding precisionRevolution surface grinding machinesBonded abrasive wheelsCylindrical grindingMaterials science

The abrasive grinding wheel includes an annular abrasive grain layer formed by a diamond abrasive grain or CBN abrasive grain and fixed to an outer peripheral surface of a cylindrical grinding wheel core by an adhesive agent. The abrasive grinding wheel further includes a waterproof agent applied on both side end surfaces and an inner peripheral surface of the cylindrical grinding wheel core in order to prevent any water ingress into the inside of the core.

Owner:TOYODA VAN MOPPES

One-time grinding device and method for double-flange sides of short cylindrical inner ring

InactiveCN104625910BImprove grinding efficiencyGrinding accuracy is easy to guaranteeEdge grinding machinesGrinding wheel securing apparatusGrinding wheelMechanical engineering

The invention discloses a one-time grinding device and method of double blocking sides of an inner ring of a short cylinder. The grinding device comprises a vertical driving device, a left-right driving device, a grinding wheel and a grinding wheel mounting seat. The vertical driving device is located on the grinding wheel mounting seat, and used for driving the grinding wheel mounting seat to move upwards or downwards; the left-right driving device is located on the grinding wheel mounting seat and used for driving the grinding wheel mounting seat to move leftwards or rightwards; the grinding wheel is mounted on the grinding wheel mounting seat, and the length of the grinding end of the grinding wheel is smaller than the width of the inner ring of the short cylinder. According to the one-time grinding device and method of the double blocking sides of the inner ring of the short cylinder, grinding of the double blocking sides of the short cylinder can be completed simply by locating the short cylinder once, and the grinding precision of the blocking sides is easy to ensure. In addition, the large grinding wheel can be adopted, and the utilization rate of the grinding wheel is obviously improved. The one-time grinding device and method of the double blocking sides of the inner ring of the short cylinder have the advantages of being high in grinding efficiency and good in grinding precision.

Owner:NINGBO MINGRUN MACHINERY MFG

One-time grinding device and method of double blocking sides of inner ring of short cylinder

InactiveCN104625910AImprove grinding efficiencyGrinding accuracy is easy to guaranteeEdge grinding machinesGrinding wheel securing apparatusEngineeringGrinding wheel

The invention discloses a one-time grinding device and method of double blocking sides of an inner ring of a short cylinder. The grinding device comprises a vertical driving device, a left-right driving device, a grinding wheel and a grinding wheel mounting seat. The vertical driving device is located on the grinding wheel mounting seat, and used for driving the grinding wheel mounting seat to move upwards or downwards; the left-right driving device is located on the grinding wheel mounting seat and used for driving the grinding wheel mounting seat to move leftwards or rightwards; the grinding wheel is mounted on the grinding wheel mounting seat, and the length of the grinding end of the grinding wheel is smaller than the width of the inner ring of the short cylinder. According to the one-time grinding device and method of the double blocking sides of the inner ring of the short cylinder, grinding of the double blocking sides of the short cylinder can be completed simply by locating the short cylinder once, and the grinding precision of the blocking sides is easy to ensure. In addition, the large grinding wheel can be adopted, and the utilization rate of the grinding wheel is obviously improved. The one-time grinding device and method of the double blocking sides of the inner ring of the short cylinder have the advantages of being high in grinding efficiency and good in grinding precision.

Owner:NINGBO MINGRUN MACHINERY MFG

Large CNC Crankshaft Main Journal Cylindrical Grinding Machine

ActiveCN103949947BReduce unbalanced centrifugal inertia forceReduce torqueRevolution surface grinding machinesGrinding drivesNumerical controlBall screw

The invention provides a large-sized numerical control cylindrical grinding machine for a crankshaft main journal, which can reduce imbalanced centrifugal inertia force of the revolving crankshaft during grinding, so as to reduce torsion and bending deflection of the crankshaft, meet the roundness processing requirement of the main journal, and realize grinding of a common outer circle of the large-sized crankshaft. The large-sized numerical control cylindrical grinding machine comprises a workpiece lathe bed and a grinding wheel lathe bed, wherein the workpiece lathe body is provided with a headstock and a tailstock; a grinding carriage is arranged on the grinding wheel lathe bed and correspond to the workpiece lathe body; the large-sized numerical control cylindrical grinding machine is characterized by that the grinding carriage is connected with the grinding wheel lathe body through a carriage; the carriage is connected with the grinding wheel lathe body through a guide rail; the grinding carriage is connected with the carriage through a servo motor and a ball screw; a narrow central frame is arranged on the workpiece lathe body; the headstock is fixed at one end of the workpiece lathe body; the tailstock is connected with the workpiece lathe body through the guide rail.

Owner:WUXI SHANGJI AUTOMATION

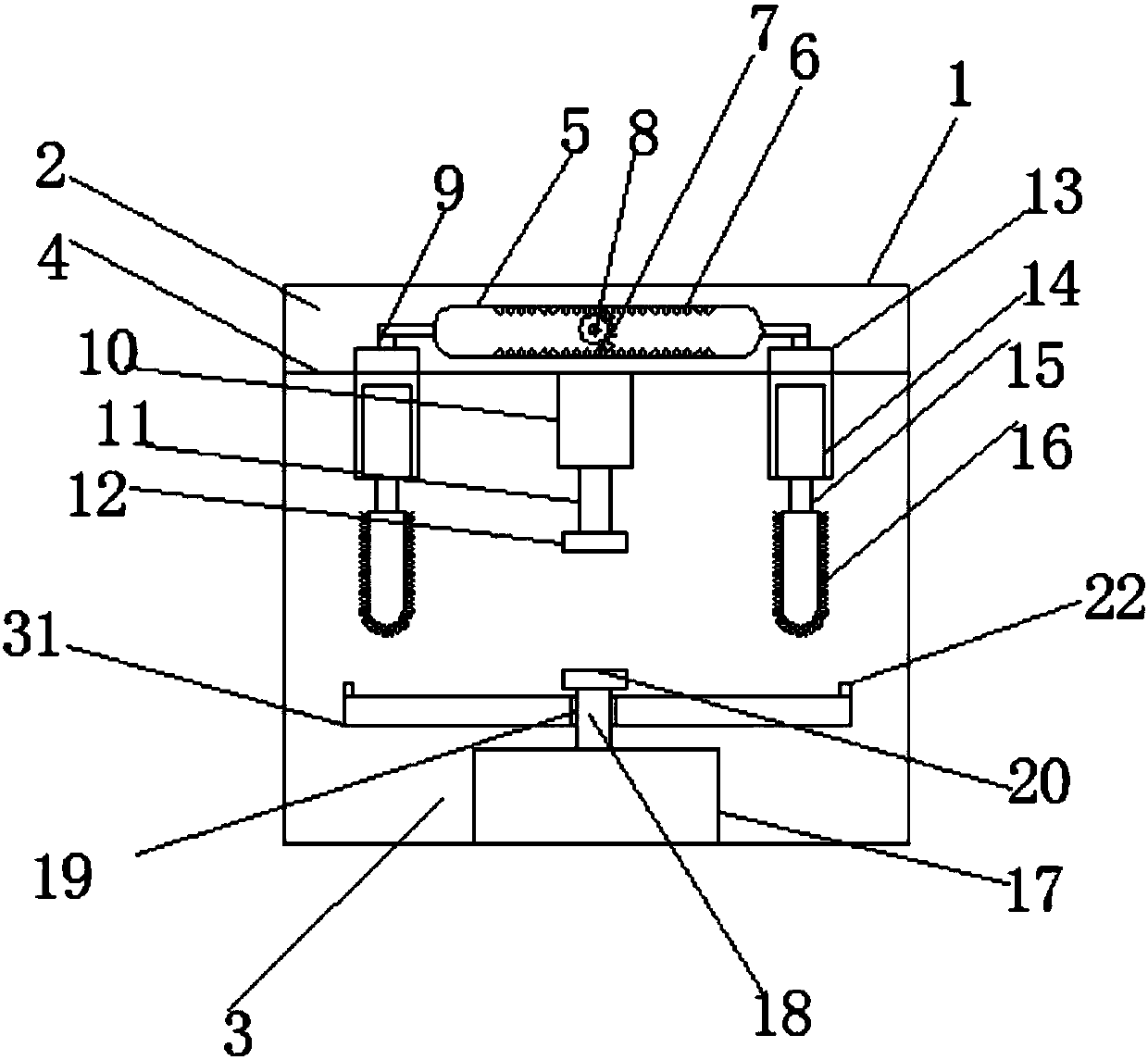

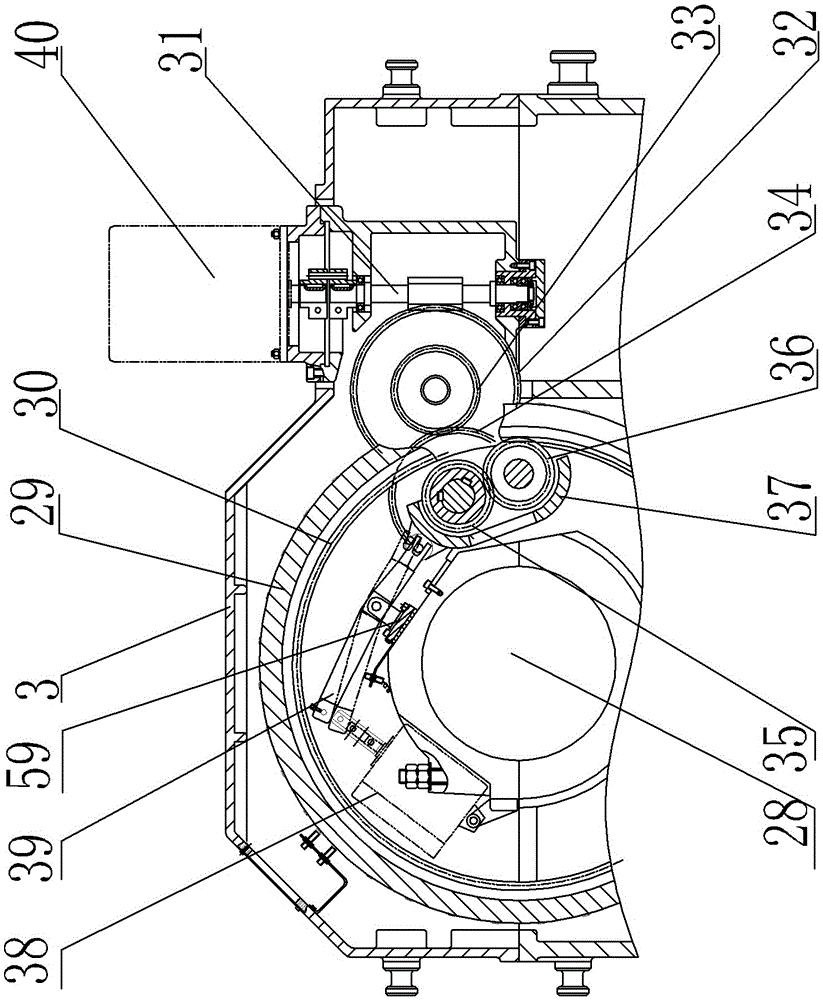

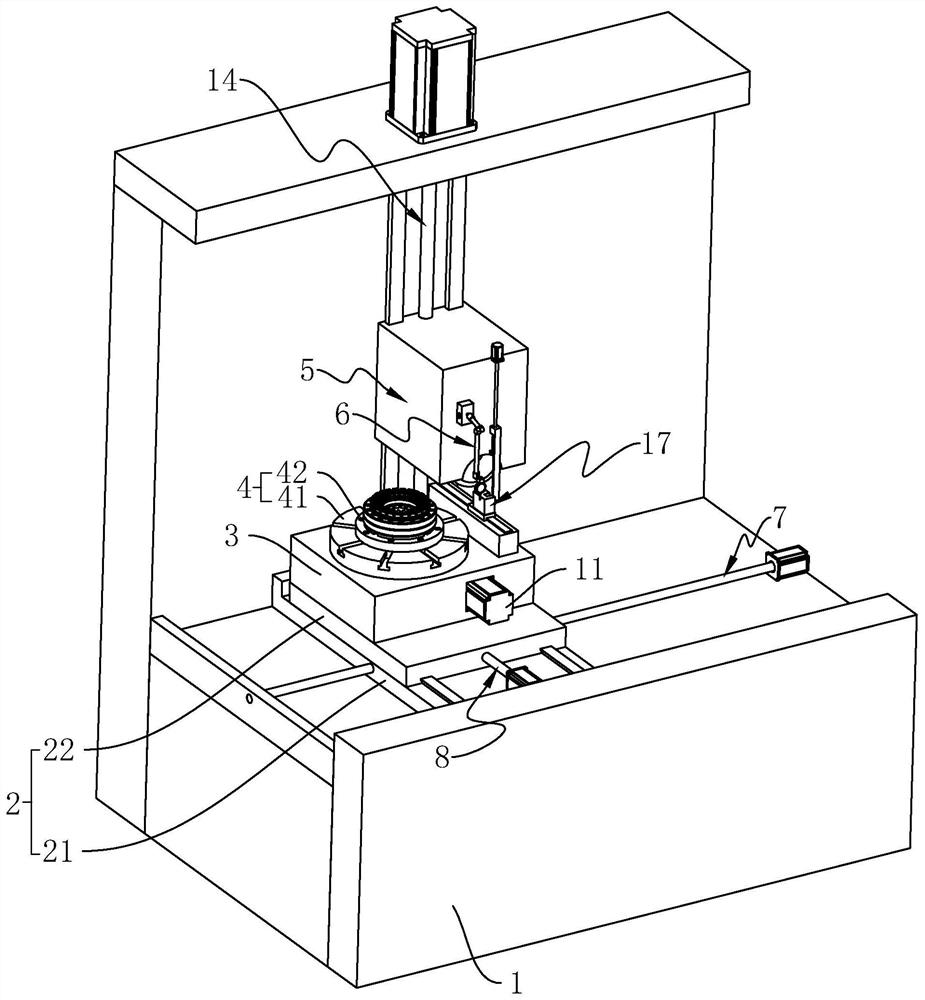

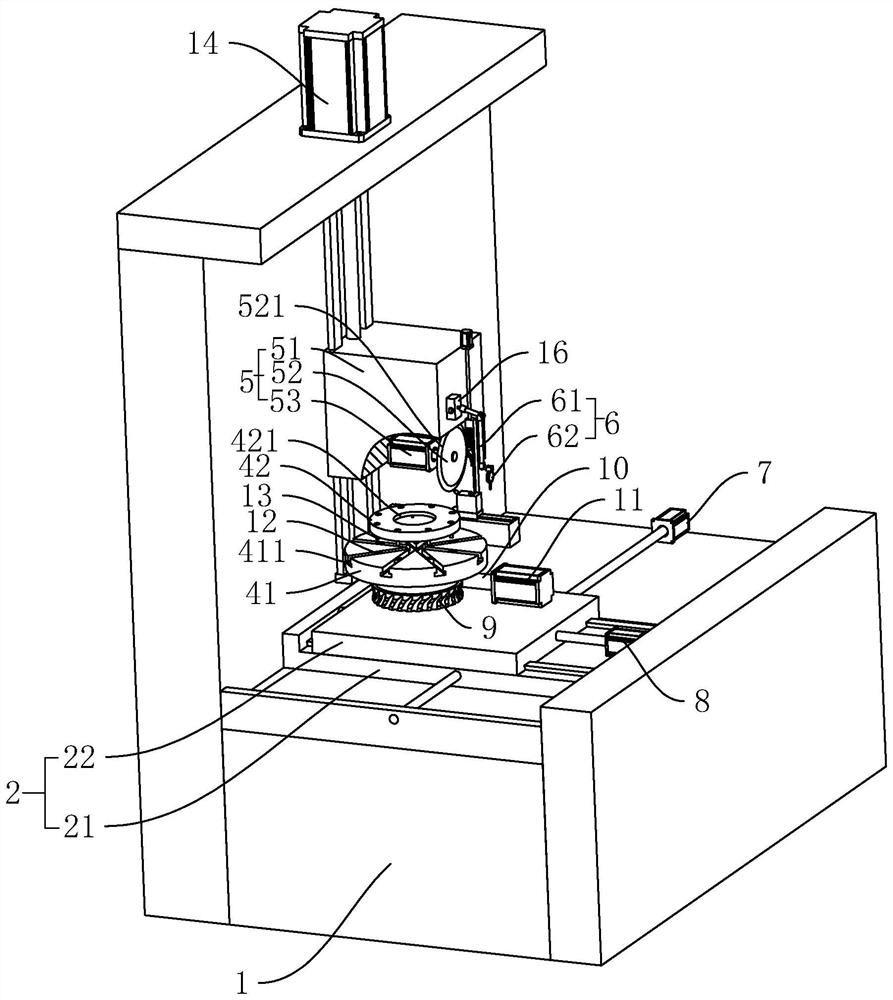

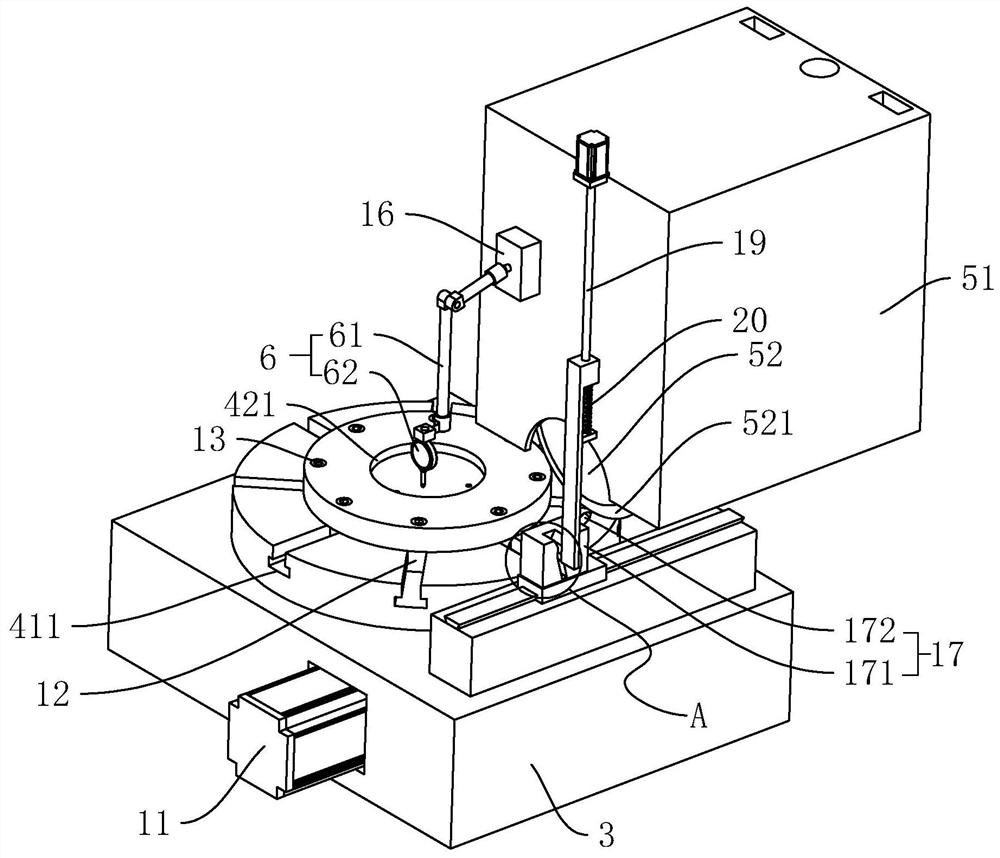

Grinding equipment and grinding method for end face gears for turrets

ActiveCN112894545BGood precisionGood grinding precisionGrinding carriagesGrinding drivesSurface toothElectric machinery

The application discloses a grinding device for end teeth for turrets, which relates to the technical field of turret processing. grinding device, the grinding device includes a grinding seat arranged on the frame, a grinding disc rotatably connected to the grinding seat, and a drive motor arranged on the grinding seat to drive the grinding disc to rotate; the rotation axis of the grinding disc is arranged perpendicular to the rotation axis of the mounting seat, The outer peripheral wall of the grinding disc is provided with an inclined surface, which corresponds to the inclined surface of the teeth of the workpiece for grinding the workpiece; the worktable slides relative to the grinding device, and the relative sliding direction of the worktable and the grinding device is perpendicular to the grinding disc The axis of rotation and perpendicular to the axis of rotation of the mount. The installation seat and the grinding device are arranged, and the grinding device performs precise grinding on the side wall of the tooth part of the workpiece, so that the precision of the end face teeth of the fixed gear ring and the positioning gear ring is better.

Owner:温岭市文昌数控机床设备有限公司

Abrasive grinding wheel

ActiveUS9539702B2Improve balanceGood grinding precisionBonded abrasive wheelsGrinding devicesCylindrical grindingA diamond

The abrasive grinding wheel includes an annular abrasive grain layer formed by a diamond abrasive grain or CBN abrasive grain and fixed to an outer peripheral surface of a cylindrical grinding wheel core by an adhesive agent. The abrasive grinding wheel further includes a waterproof agent applied on both side end surfaces and an inner peripheral surface of the cylindrical grinding wheel core in order to prevent any water ingress into the inside of the core.

Owner:TOYODA VAN MOPPES

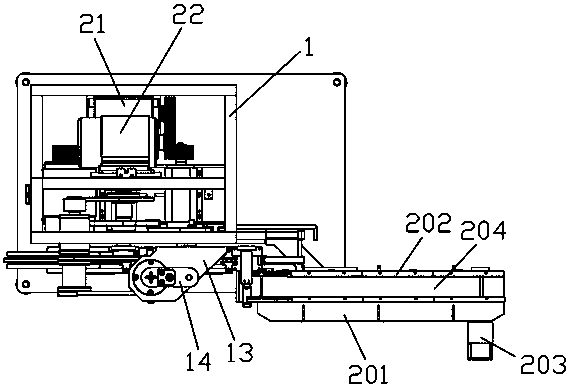

A kind of NdFeB bar grinding equipment and grinding method

ActiveCN110480455BEasy to polishEffective sandingRevolution surface grinding machinesGrinding drivesProcess engineeringIndustrial engineering

The invention relates to the field of processing NdFeB rods. A kind of NdFeB rod grinding equipment, including a support frame, a support platform, a feeding and conveying module, and a grinding assembly; the support platform is set on the support frame through a horizontal adjustment module; the feeding and conveying module includes a feeding module and delivery module; the feeding module is set at the rear of the support platform; the delivery module is set on the support platform; the delivery module is used to transport the NdFeB rods and make the NdFeB rods in The grinding component is polished; the grinding component is set in the middle of the support frame through the lifting adjustment module; the grinding component is used for grinding and forming the NdFeB rod on the conveying module. The technical effect of this patent is that a large number of NdFeB rods can be put in at the same time, and the materials can be loaded one by one in an orderly manner, so as to improve the stability of feeding, improve the conveying efficiency, and improve the grinding quality and grinding efficiency at the same time.

Owner:JIANGSU PULONG MAGNETIC ELECTRICITY CO LTD

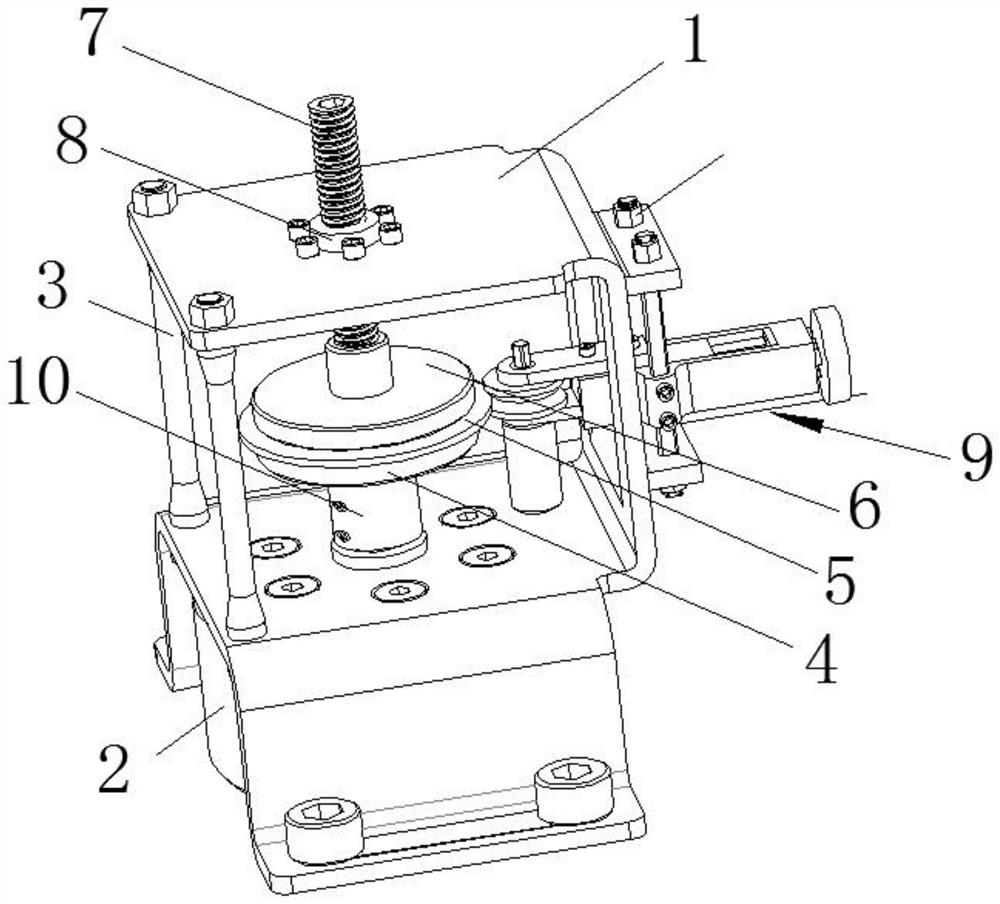

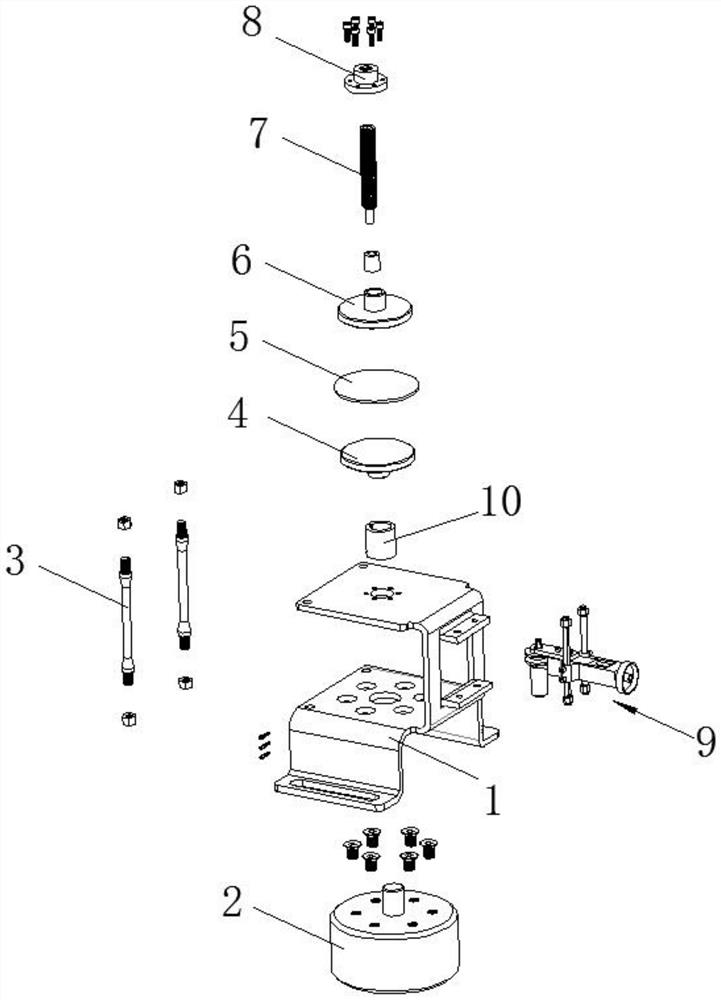

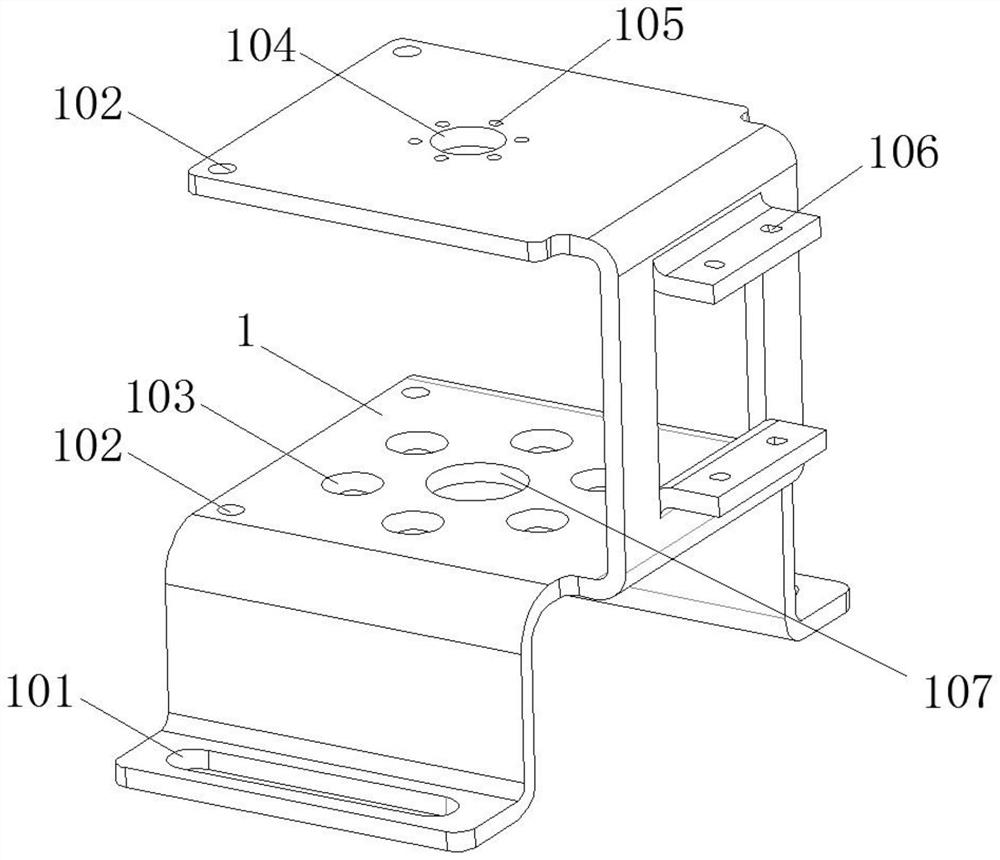

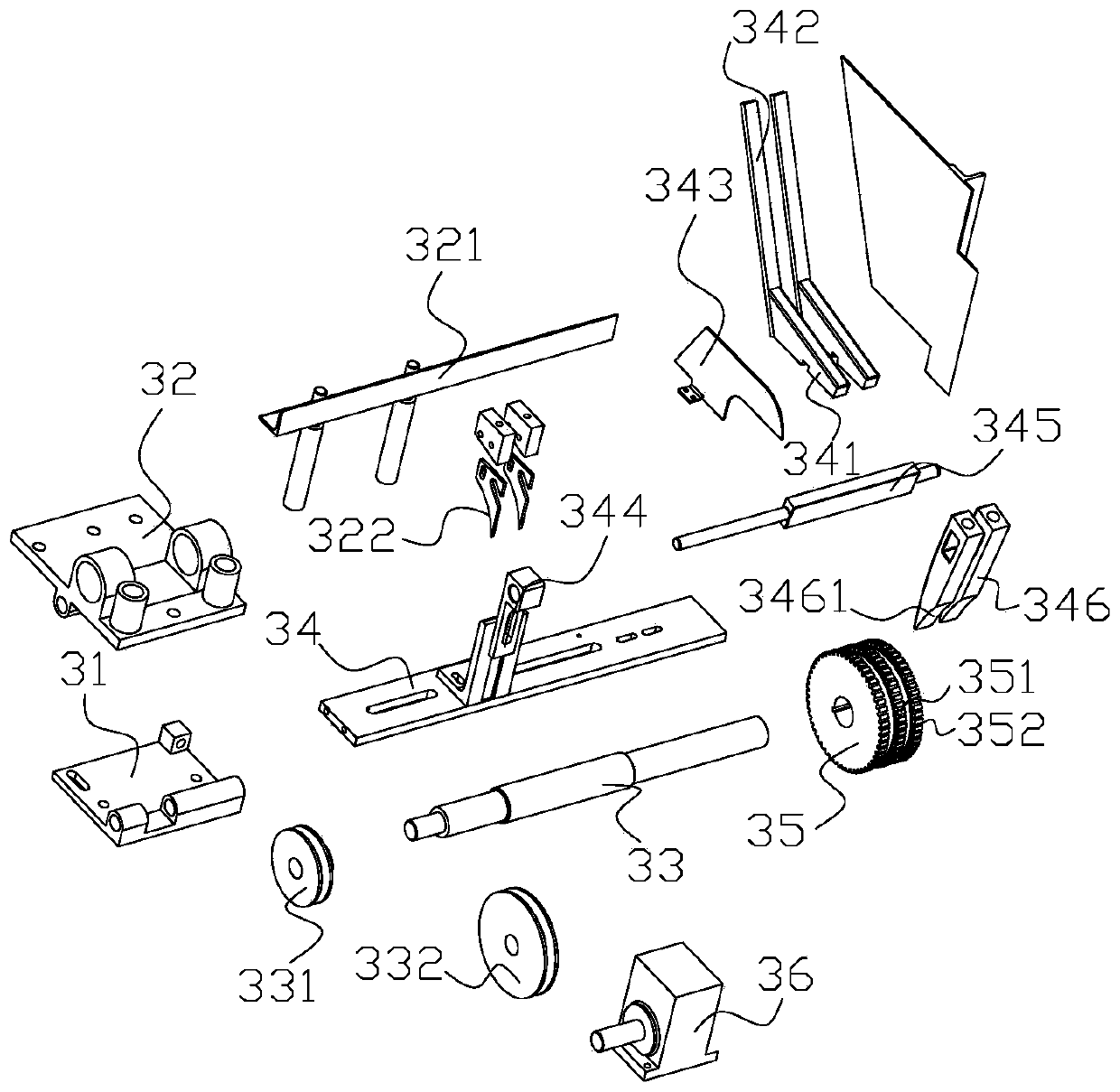

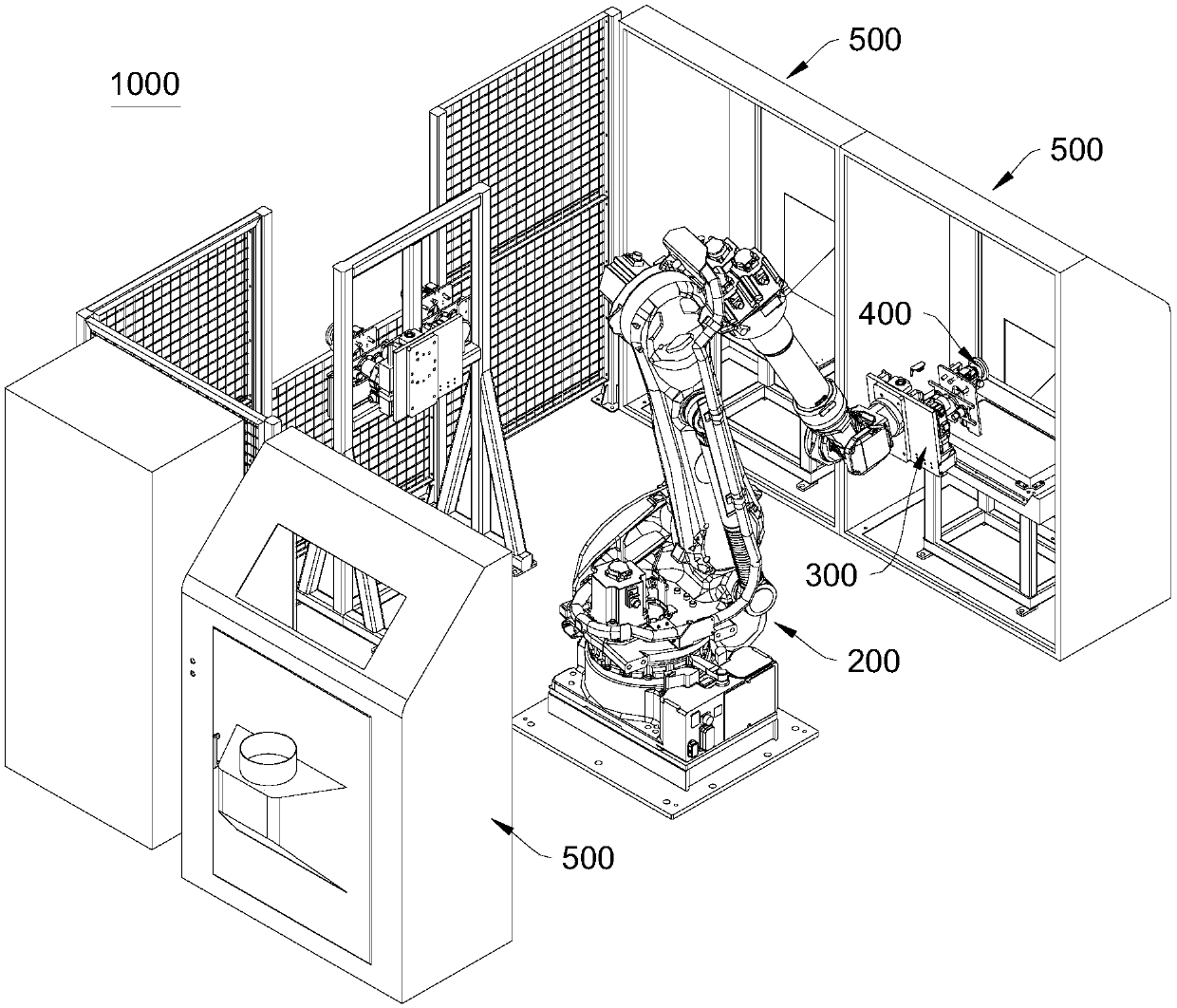

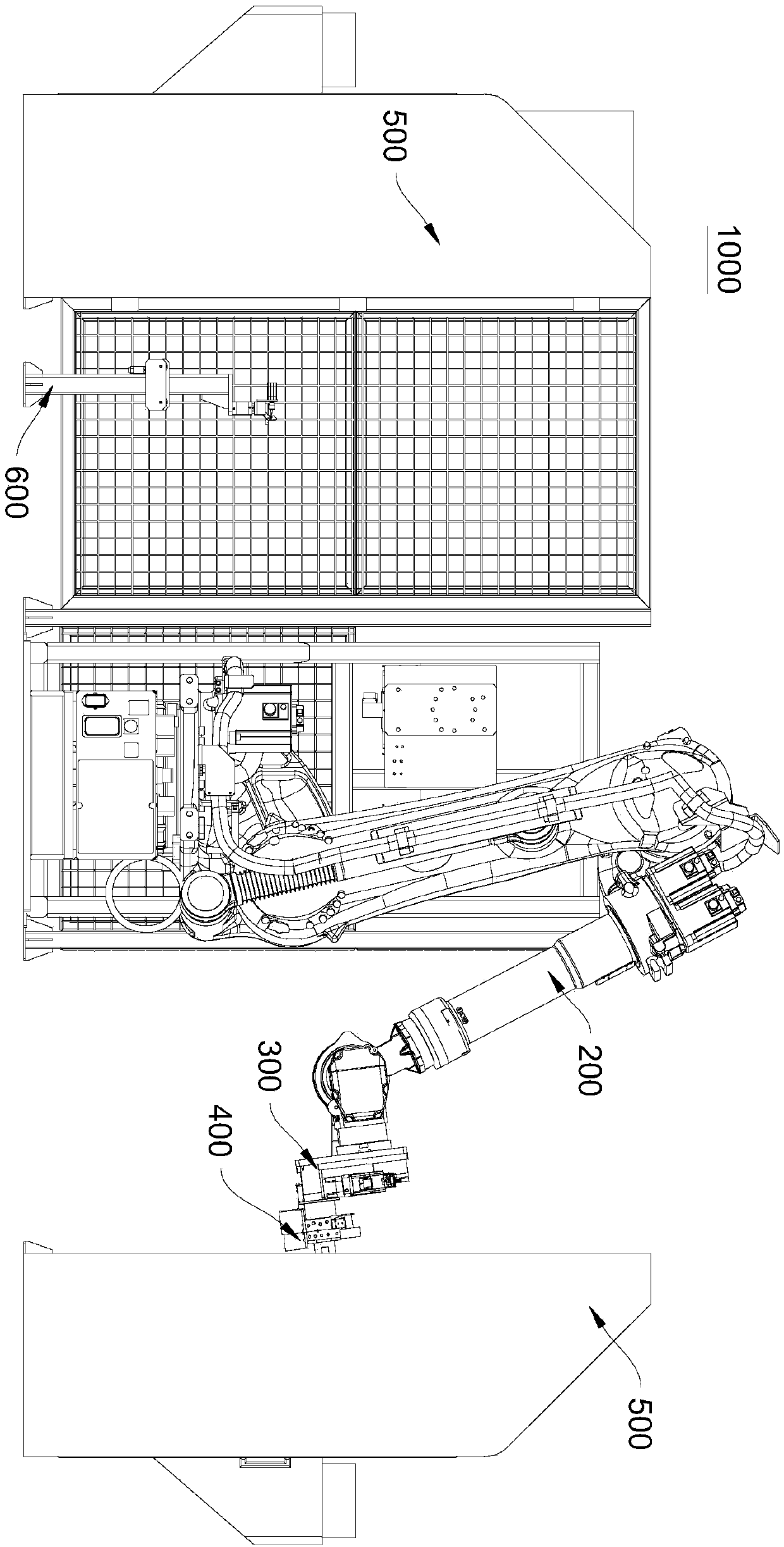

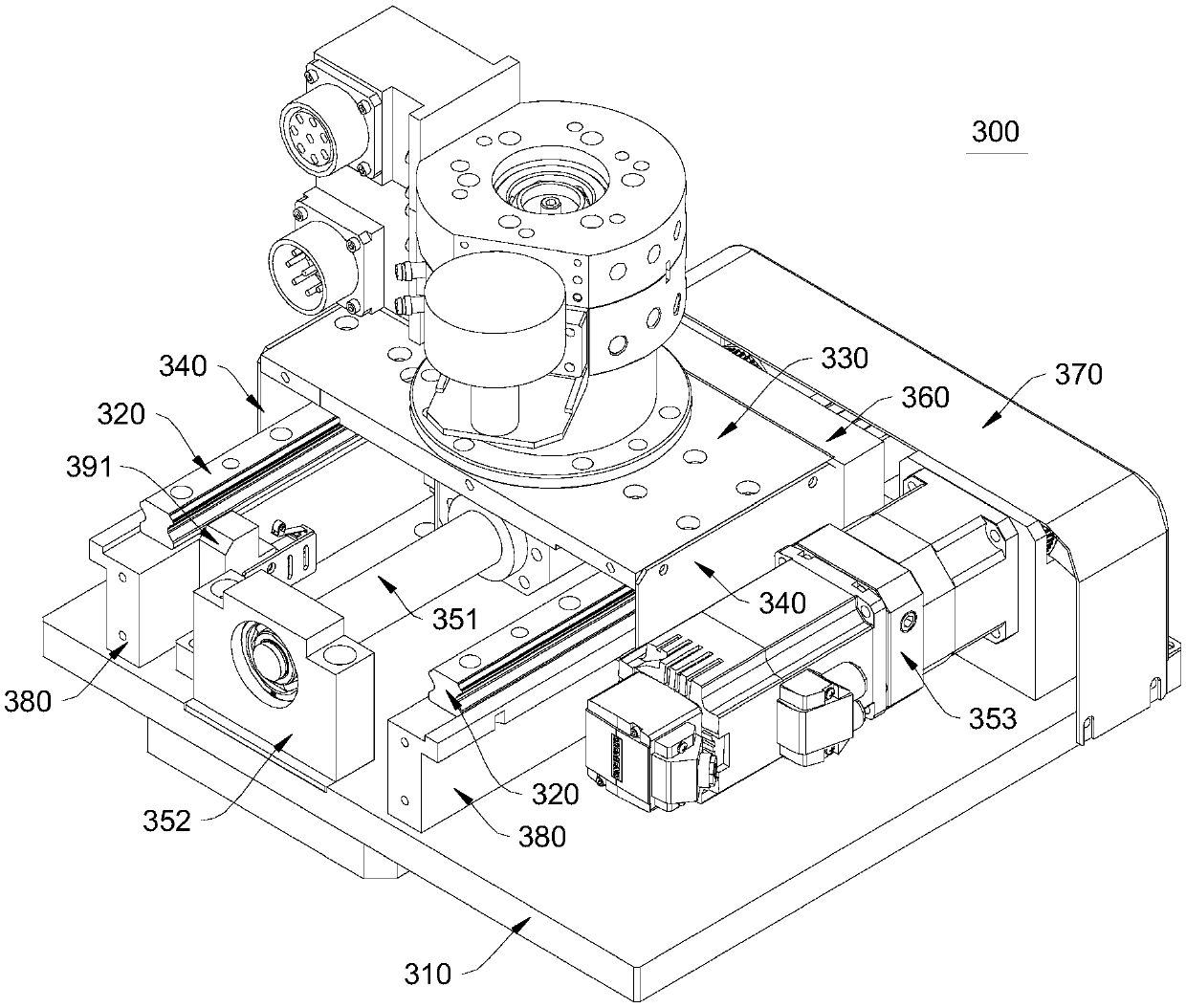

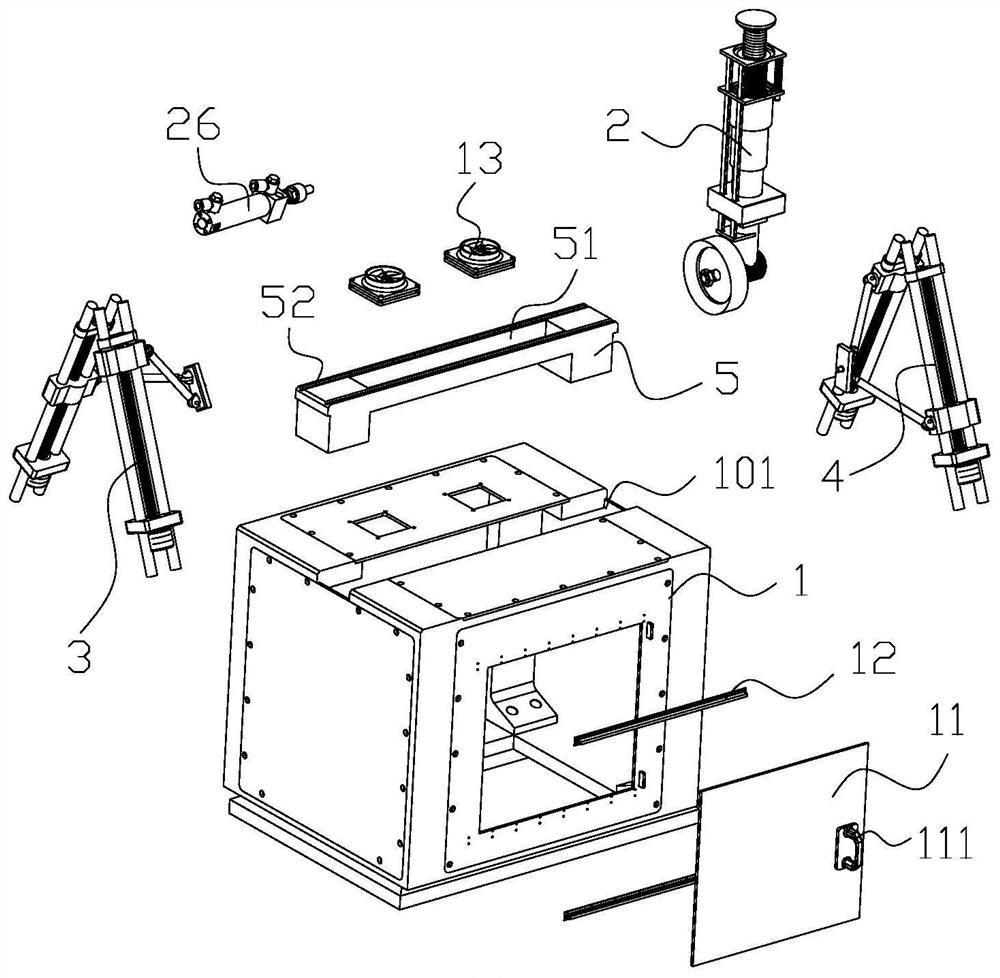

Human-simulated tool testing station

PendingCN109605213AImprove stabilityImproved sanding quality and sanding accuracyGrinding carriagesGrinding drivesEngineeringAngle grinder

The invention discloses a human-simulated tool testing station. A levelling polishing platform comprises a polishing platform, fixing blocks and beam-type switches. A cutter feeding device comprises abase seat, a moving platform, a power assembly and an organ protecting cover. The moving platform is slidably matched with a sliding rail and driven by a power device. The organ protecting cover is arranged at two ends of the moving platform correspondingly and connected between an end and an end plate of the moving platform. A mechanical arm is connected with the side, away from the moving platform, of the base seat. An angle grinder flexible attaching device comprises a base plate, a buffering plate, an angle grinder body and a buffering assembly. The base plate and the buffering plate arearranged at an interval. The buffering assembly comprises linear bearings and elastic pieces, the linear bearings are connected between the base plate and the buffering plate, and the elastic pieces are connected between the base plate and the buffering plate in an abutting mode. The angle grinder body is arranged on the side, away from the buffering assembly, of the buffering plate. The side, away from the buffering plate, of the base plate is connected to the side, away from the base plate, of the moving plate through a quick changing device. According to the human-simulated tool testing station, the machining precision is high, and the quality of products is good.

Owner:四川纽赛特工业机器人制造有限公司

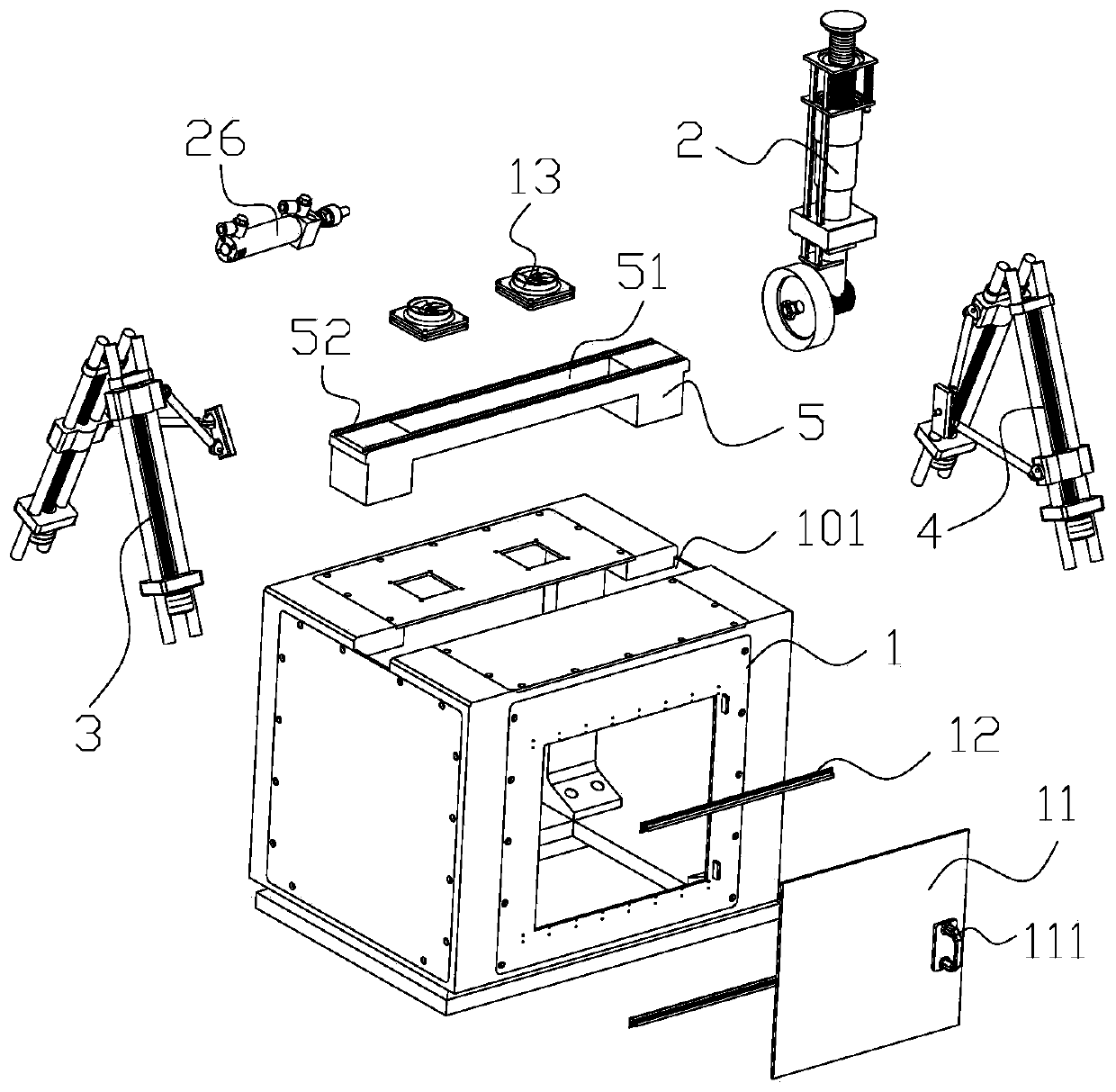

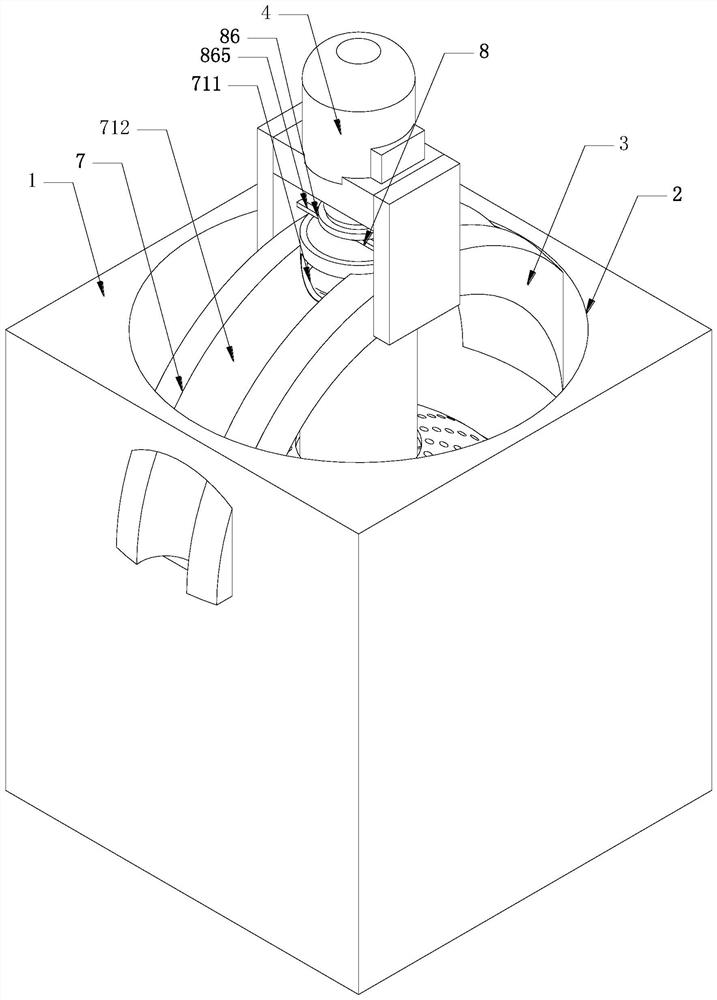

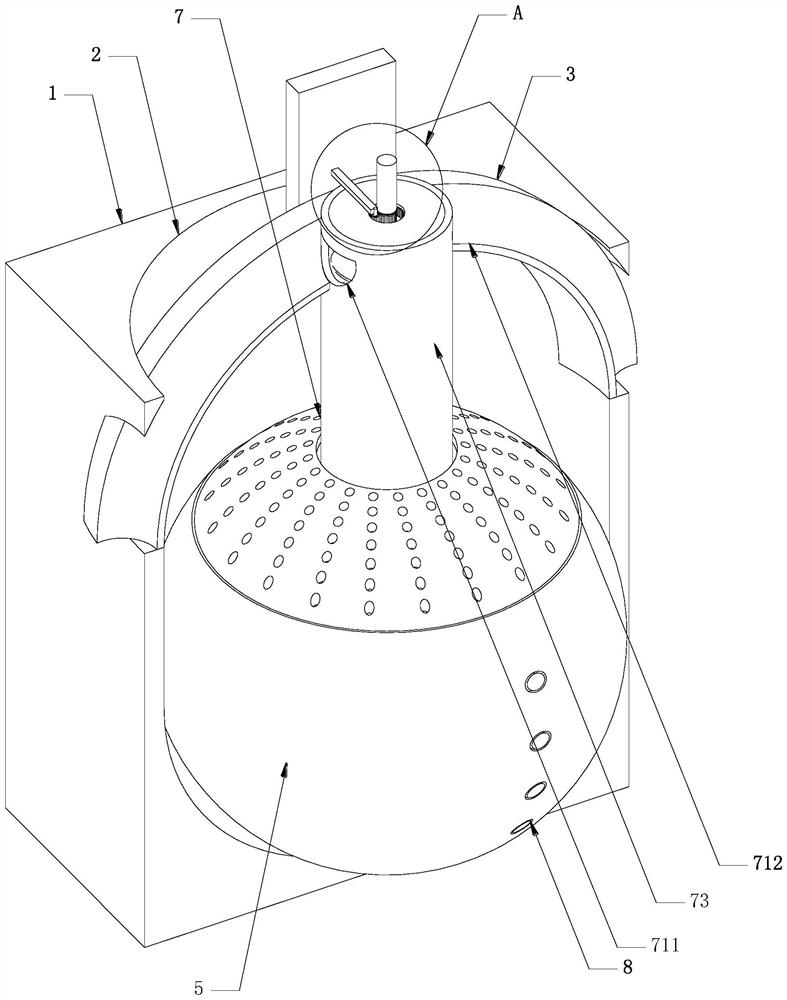

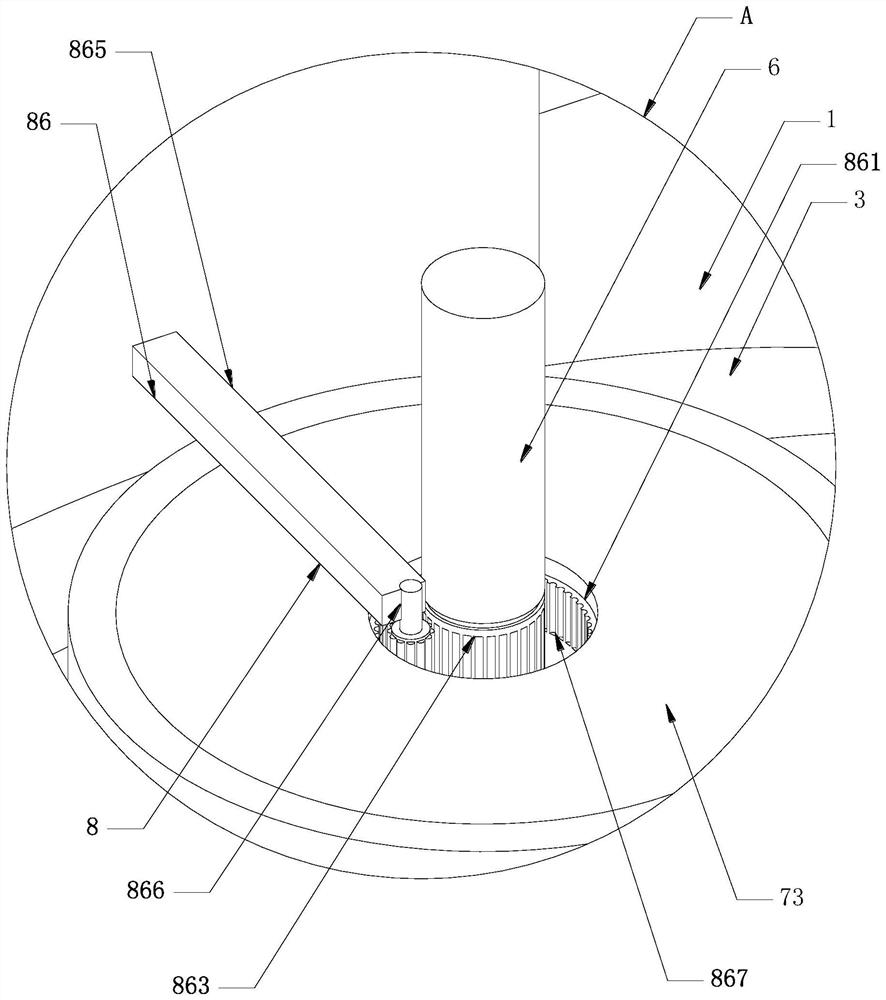

Grinding device and grinding method for spiral blade for machining pump

ActiveCN110405583ARealize automatic processingEasy to controlGrinding drivesGrinding machinesSpiral bladeEngineering

The invention relates to the technical field of machining. The invention discloses a grinding device for a spiral blade for a machining pump. The grinding device for the spiral blade for the machiningpump comprises a case, a grinding assembly, a first rotary drive assembly and a second rotary drive assembly, a neutral gear is arranged in the middle of the top surface of the case, and a slide railis arranged on the neutral gear; a slide rail neutral gear is arranged the middle of the slide rail, the grinding assembly is matched with the slide rail, the first rotary drive assembly and the second rotary drive assembly are arranged on the left side and the right side of the case, the lower end of the first rotary drive assembly is arranged on the case, the upper end of the first rotary driveassembly is arranged on the slide rail, a part is fixed between the first rotary drive assembly and the second rotary drive assembly, and the part is polished into a spiral shape through the grindingassembly matched with the first rotary drive assembly and the second rotary drive assembly. The grinding device and grinding method have the technical effects that the cost of the device is low, thestructure is ingenious, the operation is convenient and rapid, the machining efficiency is high, and the automatic machining of the spiral blade is realized.

Owner:肇庆全球泵业有限公司

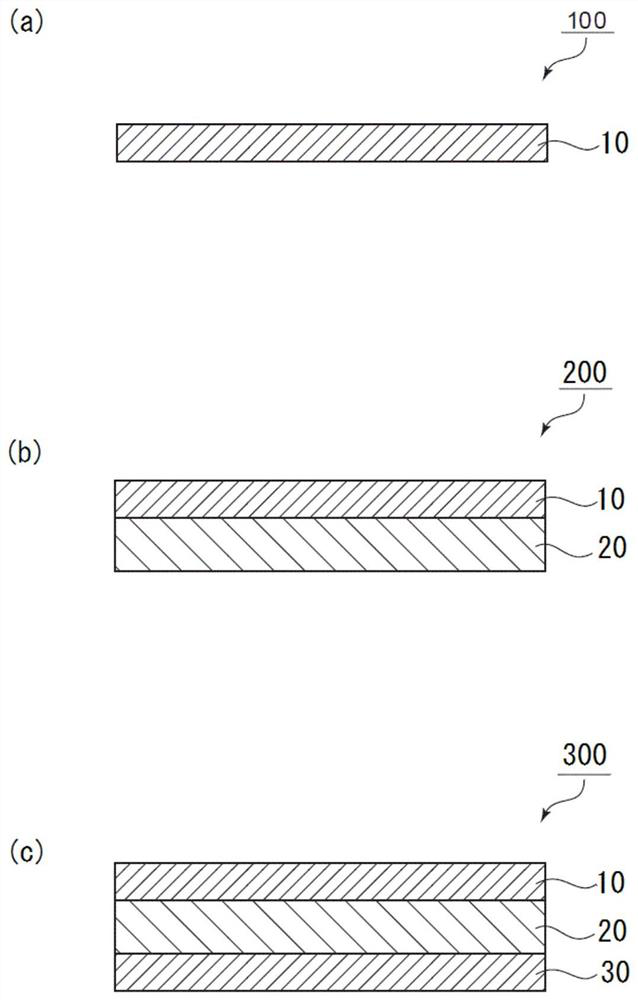

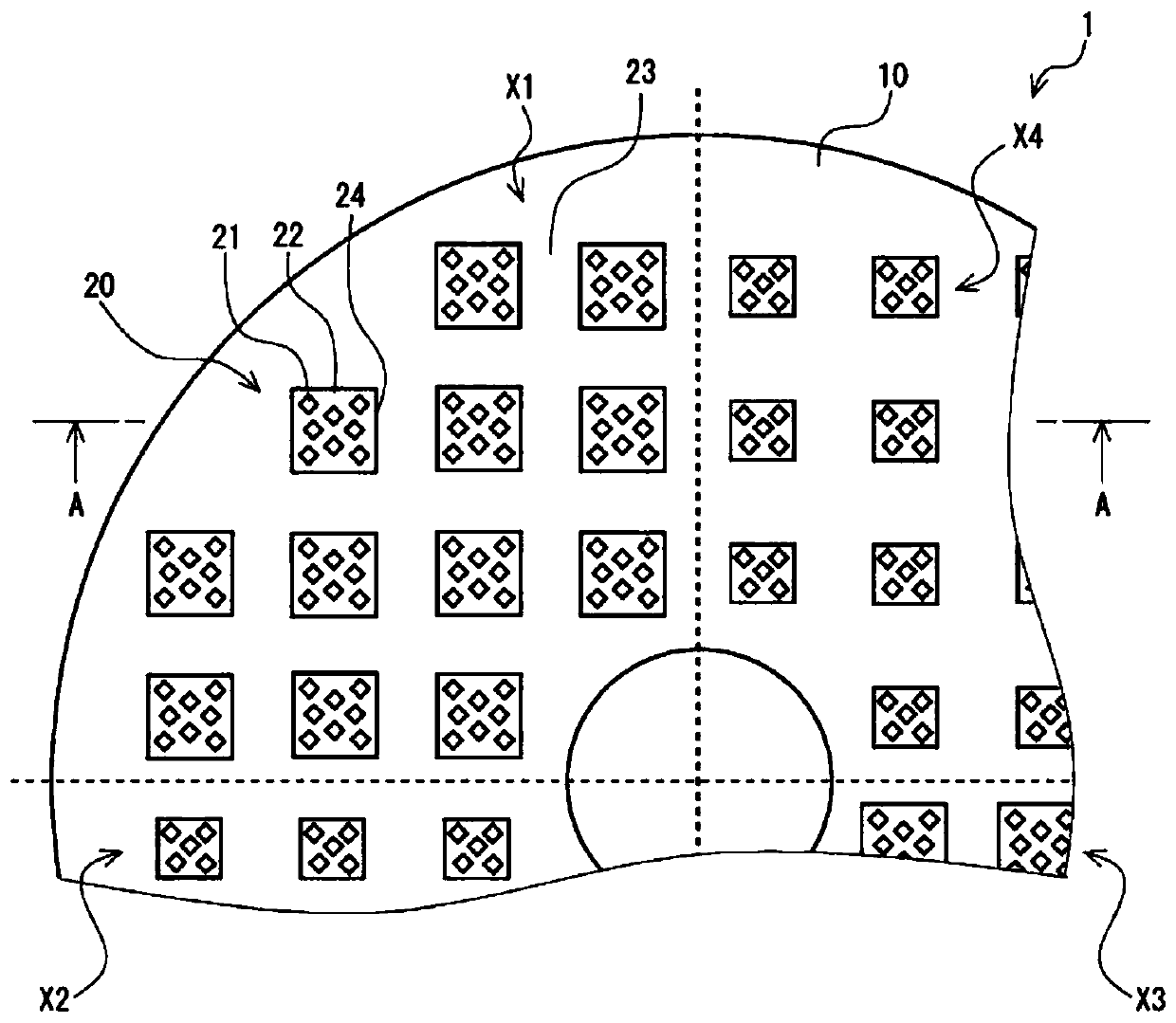

Abrasives

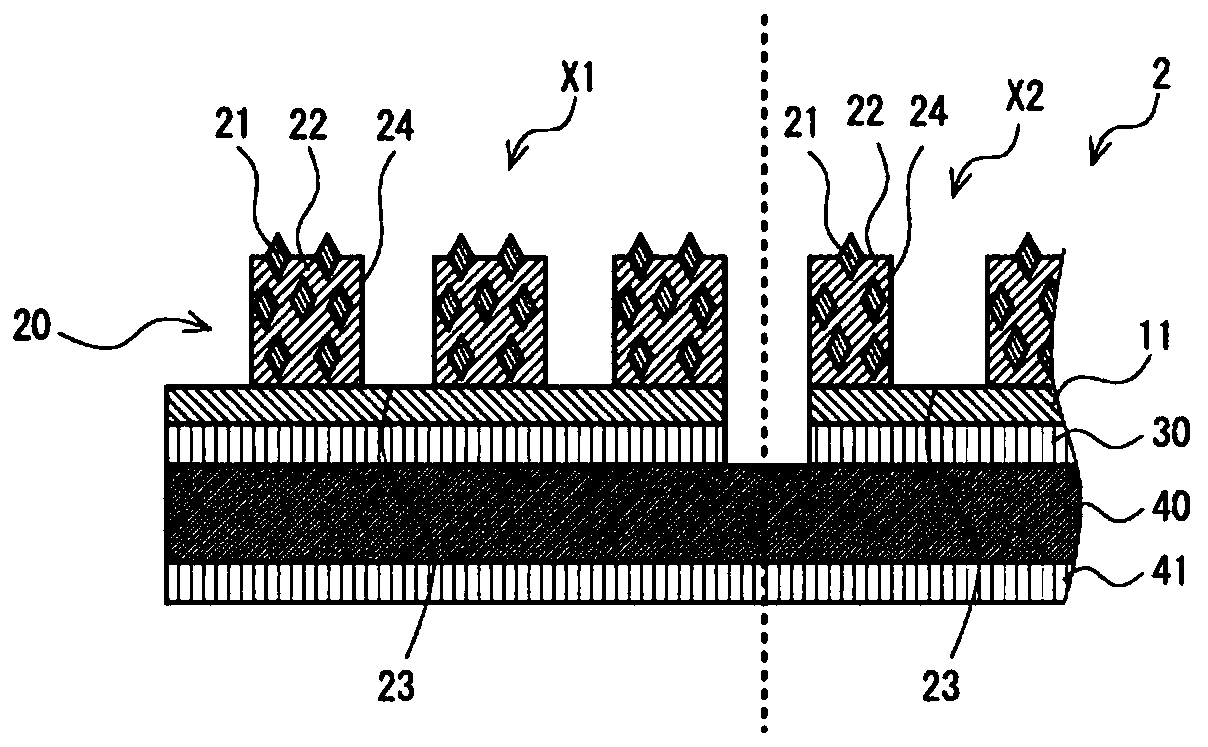

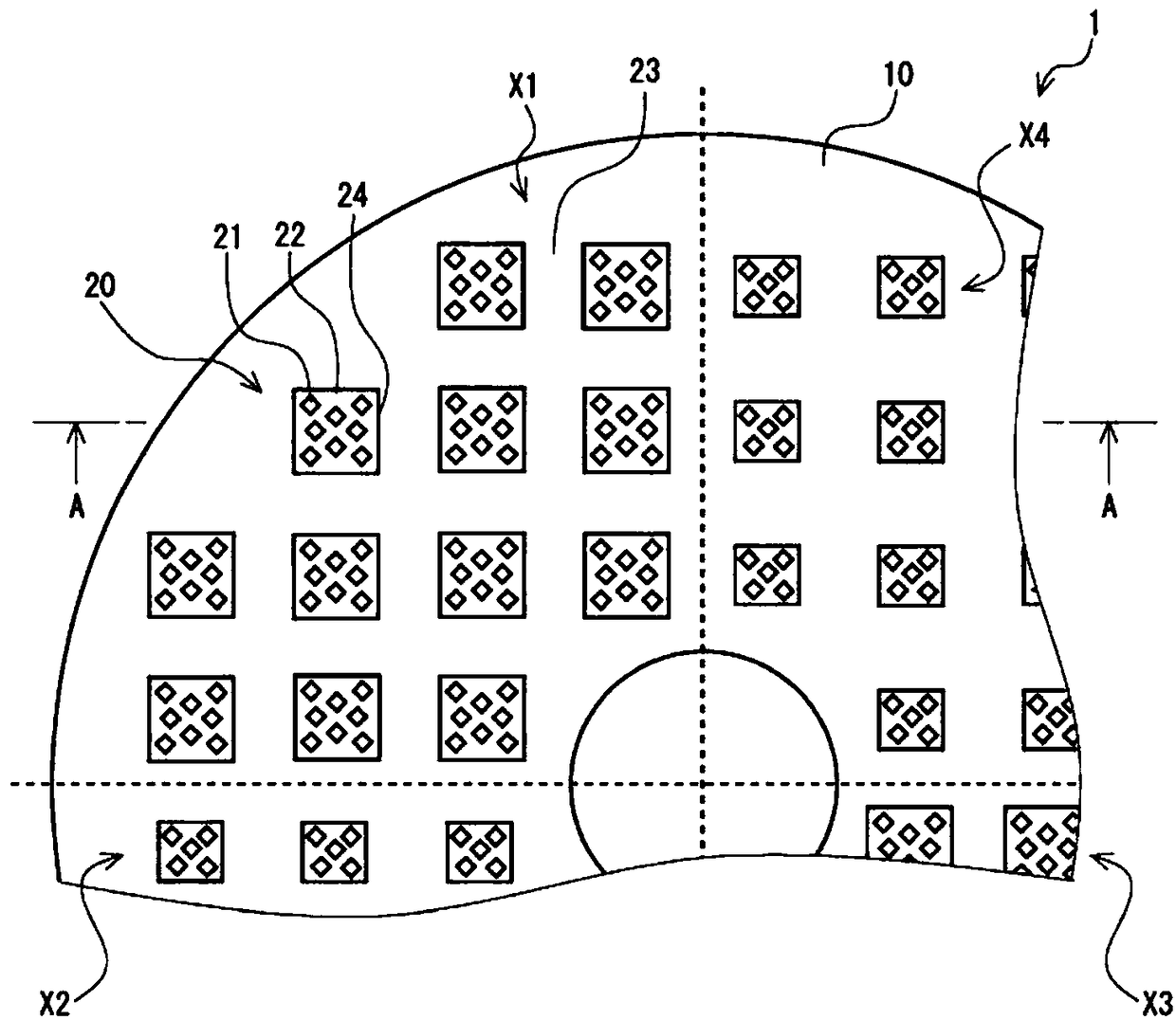

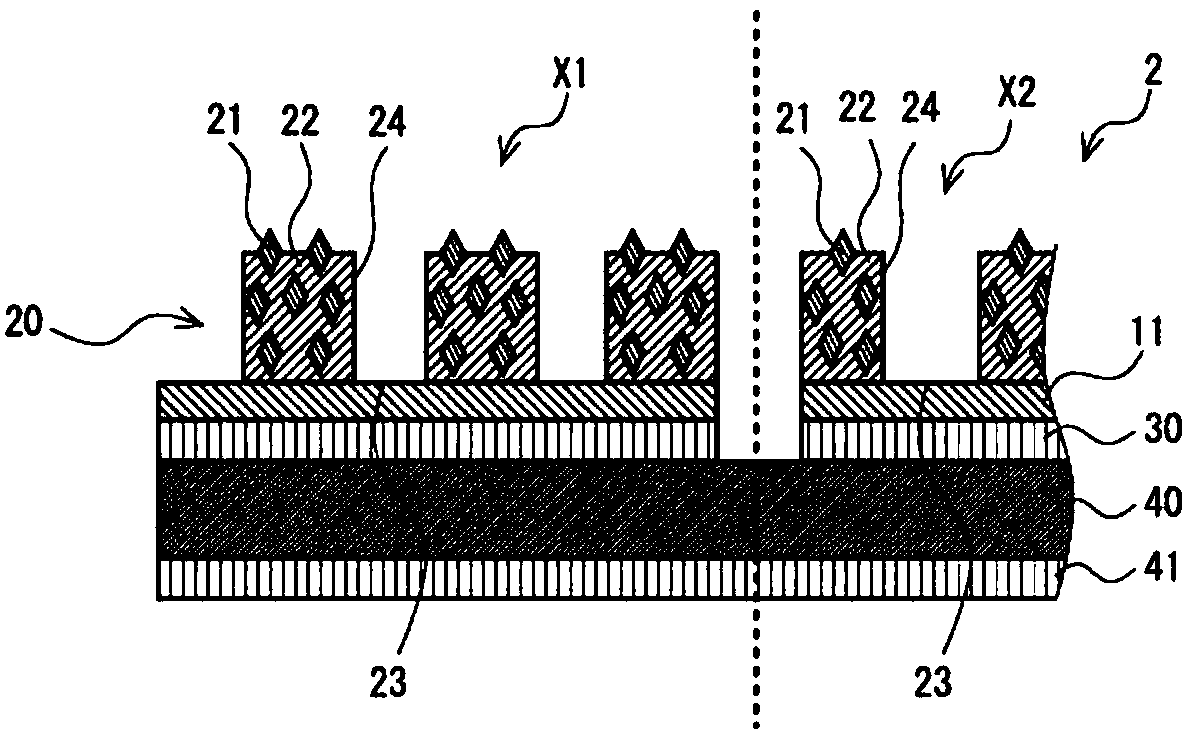

ActiveCN108472789BGood grinding precisionReduce grinding efficiencySemiconductor/solid-state device manufacturingBonded abrasive wheelsPolishingMaterials science

The object of the present invention is to provide a grinding material with low grinding efficiency and relatively low grinding cost. The abrasive material has a base material, and a grinding layer laminated on the surface side of the base material and containing abrasive grains and a binder thereof, and the grinding layer has a plurality of grinding parts divided by grooves on its surface, And there are multiple kinds of regions having different occupied area ratios of a plurality of polished parts along the polishing direction, and the difference in the occupied area ratios of the plurality of polished parts of a pair of said regions adjacent along the polishing direction is 3% or more and 21% the following. The regions may have a size that may comprise a circle having a diameter of 5 cm in plan view. In a pair of adjacent regions along the polishing direction, the occupied area ratio of the plurality of polished portions in one region is preferably 4.5% to 9%, and the occupied area ratio of the plurality of polished portions in the other region is preferably 9%. % or more and 16% or less.

Owner:BANDO CHEM IND LTD

Abrasive material

ActiveCN108472789AGood grinding precisionReduce grinding efficiencySemiconductor/solid-state device manufacturingBonded abrasive wheelsMetallurgyArea ratio

The purpose of the present invention is to provide an abrasive material in which the polishing efficiency does not readily decrease and in which the polishing cost is relatively low. This abrasive material is provided with a substrate and a polishing layer which is laminated on the obverse-surface side of the substrate and which includes abrasive grains and a binder therefor, wherein: the polishing layer has, along the polishing direction, a plurality of types of regions which have provided on the surface thereof a plurality of polishing parts divided by grooves and in which the plurality of polishing parts have different occupancy area ratios; and the difference in occupancy area ratio of the plurality of polishing parts between a pair of the regions adjacent along the polishing directionis 3%-21%. Each of the regions may be of such size as to be capable of encompassing a circle having a diameter of 5 cm in plan view. With regard to a pair of regions adjacent along the polishing direction, the occupancy area ratio of the plurality of polishing parts in one of the pair of regions is preferably 4.5%-9% and the occupancy area ratio of the plurality of polishing parts in the other ofthe pair of regions is preferably 9%-16%.

Owner:BANDO CHEM IND LTD

Method for producing rubber roller

InactiveCN100471623CGood grinding precisionShorten grinding timeRevolution surface grinding machinesBonded abrasive wheelsEngineeringGrinding wheel

Owner:SUMITOMO RUBBER IND LTD

Adhesive sheet

ActiveCN112714786AReduce pollutionReduce productivityMonocarboxylic acid ester polymer adhesivesSolid-state devicesPolymer sciencePolymer chemistry

Provided is an adhesive sheet that can be used to grind a hard and brittle substrate during backgrinding of the hard and brittle substrate and that makes it possible to reduce pollution and achieve excellent productivity, grinding precision, and release. This adhesive sheet comprises an adhesive layer. The thickness of the adhesive layer is 1-300 [mu]m. The indentation hardness H (Pa) of the adhesive layer at 25 DEG C and the thickness hA ([mu]m) of the adhesive layer satisfy the relationship in expression (1): logH>=1.9385*loghA+4.2611.

Owner:NITTO DENKO CORP

Granularity shaping equipment for chrome corundum production and use method

PendingCN114851070AContact grinding effectClear in real timeEdge grinding machinesPolishing machinesMechanical fanGear wheel

The invention relates to the technical field of chrome corundum production, in particular to granularity shaping equipment for chrome corundum production and a using method, the granularity shaping equipment comprises a grinding box, and an open type injection opening is formed in the top of the grinding box. According to the granularity shaping equipment for chrome corundum production and the use method, a blade shaft and a gear of a mechanical fan climb along a gear ring on the surface of a sleeve and reversely drive the blade shaft and the mechanical fan to rotate, and the rotating mechanical fan carries out air suction and exhaust from bottom to top in an L-shaped air duct; dust in the grinding box penetrates through the large-aperture baffle to be sucked into the straight-through groove and the sleeve until the dust is filtered and covered on the dust filter screen, and the auger rotating forwards along with the main shaft can synchronously convey the dust in the sleeve upwards until the dust is discharged through the guide-out opening and the guide groove, so that the ground dust is cleared out in real time in the grinding process, and the grinding efficiency is improved. And the influence of dust on contact grinding of the grinding balls, the chrome corundum and the grinding box can be effectively avoided, and good grinding precision is guaranteed.

Owner:淄博市淄川金龙磨料磨具有限公司

Grinding device and grinding method for processing spiral blades for pumps

ActiveCN110405583BRealize automatic processingEasy to controlGrinding drivesGrinding machinesSpiral bladeEngineering

The invention relates to the technical field of machining. A grinding device for processing helical blades for pumps, comprising a case, a grinding assembly, a first rotating drive assembly, and a second rotating drive assembly; a neutral gear is provided in the middle of the top surface of the housing, and a slide rail is provided on the neutral gear; the middle part of the slide rail The neutral position of the slide rail is provided; the grinding assembly is matched with the slide rail; the first rotary drive assembly and the second rotary drive assembly are respectively arranged on the left and right sides of the chassis; the lower end of the first rotary drive assembly is arranged on the chassis, and the first rotary The upper end of the driving assembly is set on the slide rail; the parts are fixed between the first rotating driving assembly and the second rotating driving assembly, and the parts are ground into a spiral shape through the cooperation of the grinding assembly with the first rotating driving assembly and the second rotating driving assembly . The technical effect of the patent is that the cost of the device is low, the structure is ingenious, the operation is convenient and fast, the processing efficiency is high and the automatic processing of the spiral blade is realized.

Owner:肇庆全球泵业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com