Large CNC Crankshaft Main Journal Cylindrical Grinding Machine

A cylindrical grinding machine and main journal technology, which is applied in the field of large-scale CNC crankshaft main journal cylindrical grinding machines, can solve the problems of increasing crankshaft torsion and bending deformation, poor crankshaft bending degree and torsional stiffness, large unbalanced centrifugal inertial force, etc. Achieve the effect of reducing torsion and bending deformation, good grinding accuracy and reasonable grinding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

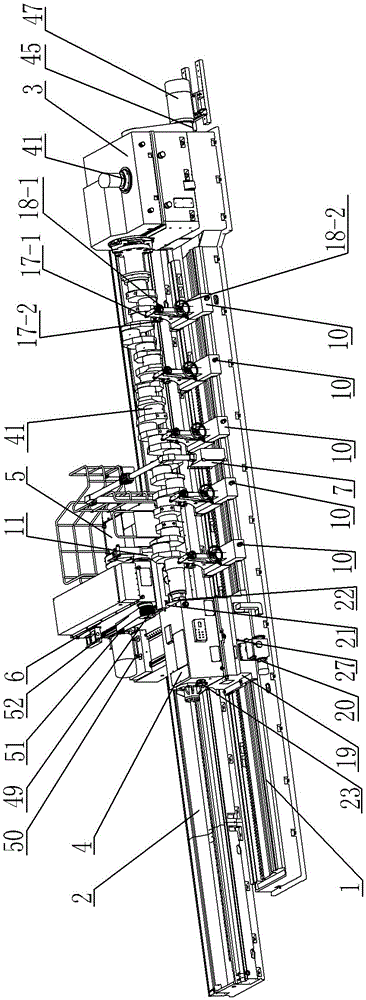

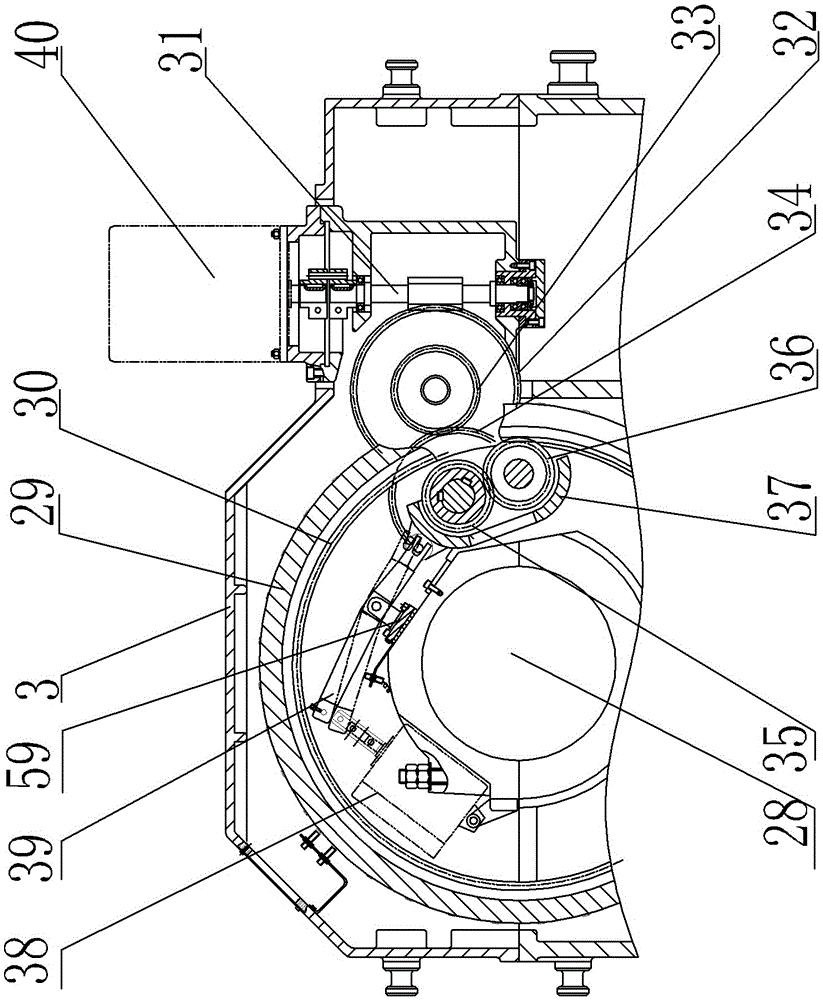

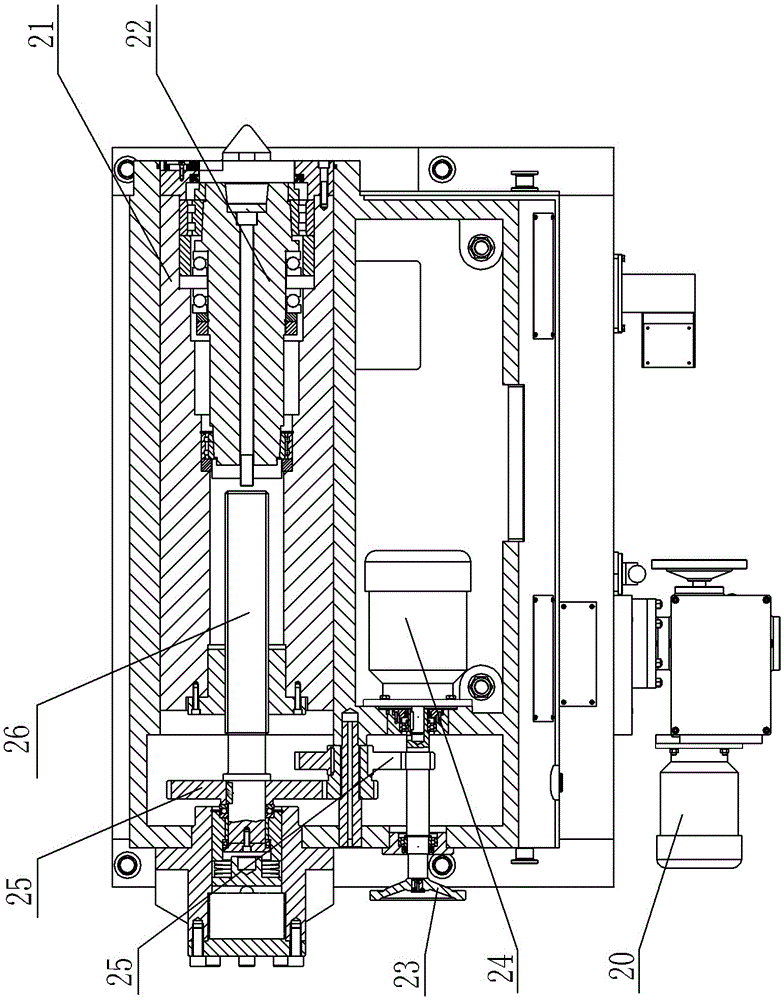

[0019] See figure 1 , figure 2 , a large-scale CNC crankshaft main journal cylindrical grinding machine, which includes a workpiece bed 1, a grinding wheel bed 2, a headstock 3 and a tailstock 4 are arranged on the workpiece bed 1, and a corresponding workpiece bed 1 is arranged on the grinding wheel bed 2 There is a grinding wheel frame 6, and the grinding wheel frame 6 is connected to the grinding wheel bed 2 through the carriage 5, and the carriage 5 is connected to the grinding wheel bed 2 through the guide rail. The carriage 5 is provided with a control box 7, and the grinding wheel frame 6 is connected to the servo motor 8 and the ball screw. 9 Connect the carriage 5, the workpiece bed 1 is provided with a plurality of narrow center frames 10, the head frame 3 is fixed on one end of the workpiece bed 1, the tailstock 4 is connected to the workpiece bed 1 through guide rails, and the grinding wheel is installed on the carriage Frame 6.

[0020] The carriage 5 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com