Human-simulated tool testing station

A technology of testing stations and tools, which is applied in the direction of manufacturing tools, metal processing equipment, and grinding machine parts, etc., can solve problems such as not being suitable for large-scale promotion and use, damage to processed objects, and affecting product quality, so as to improve the grinding quality And grinding accuracy, improve cleanliness, good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

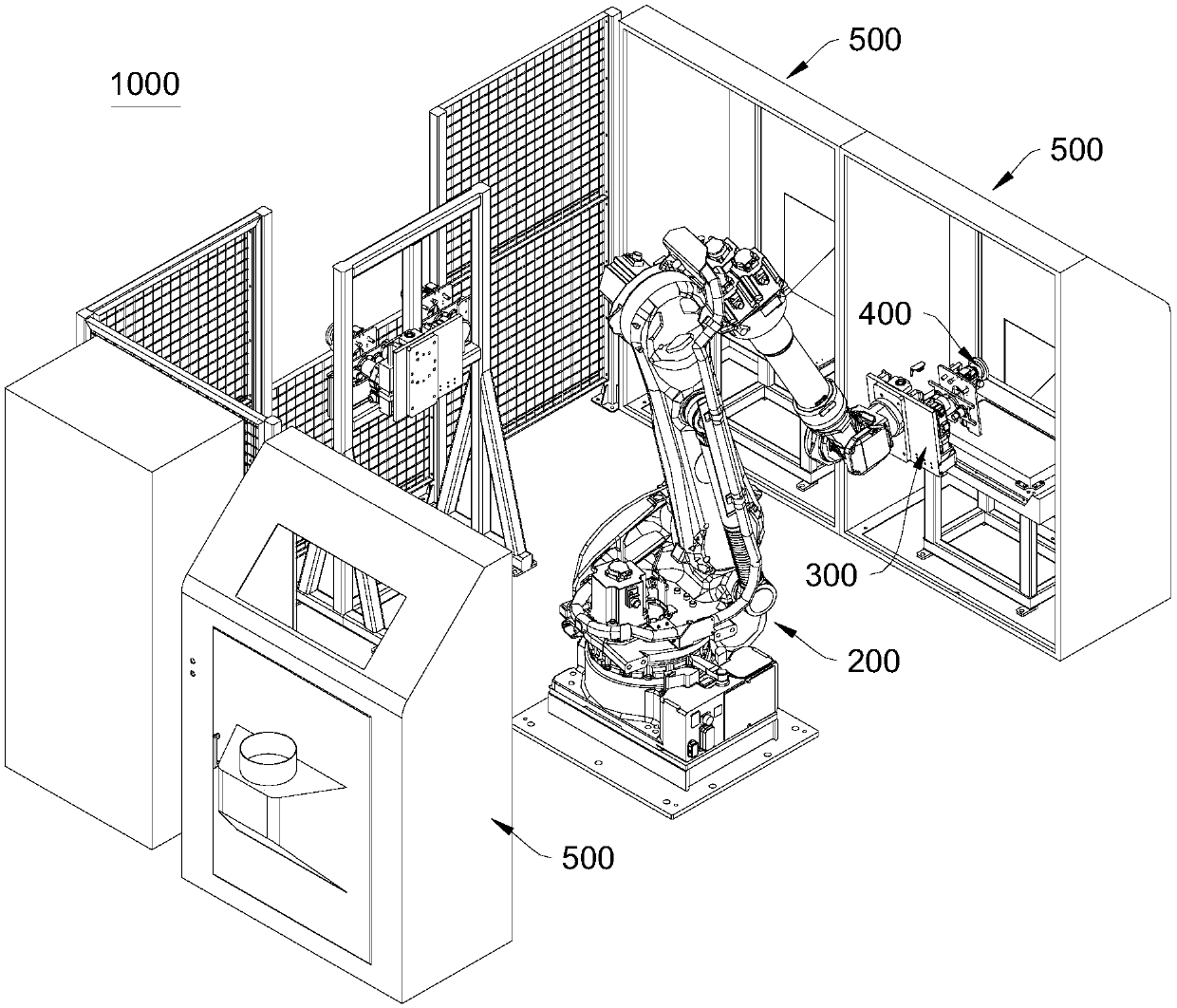

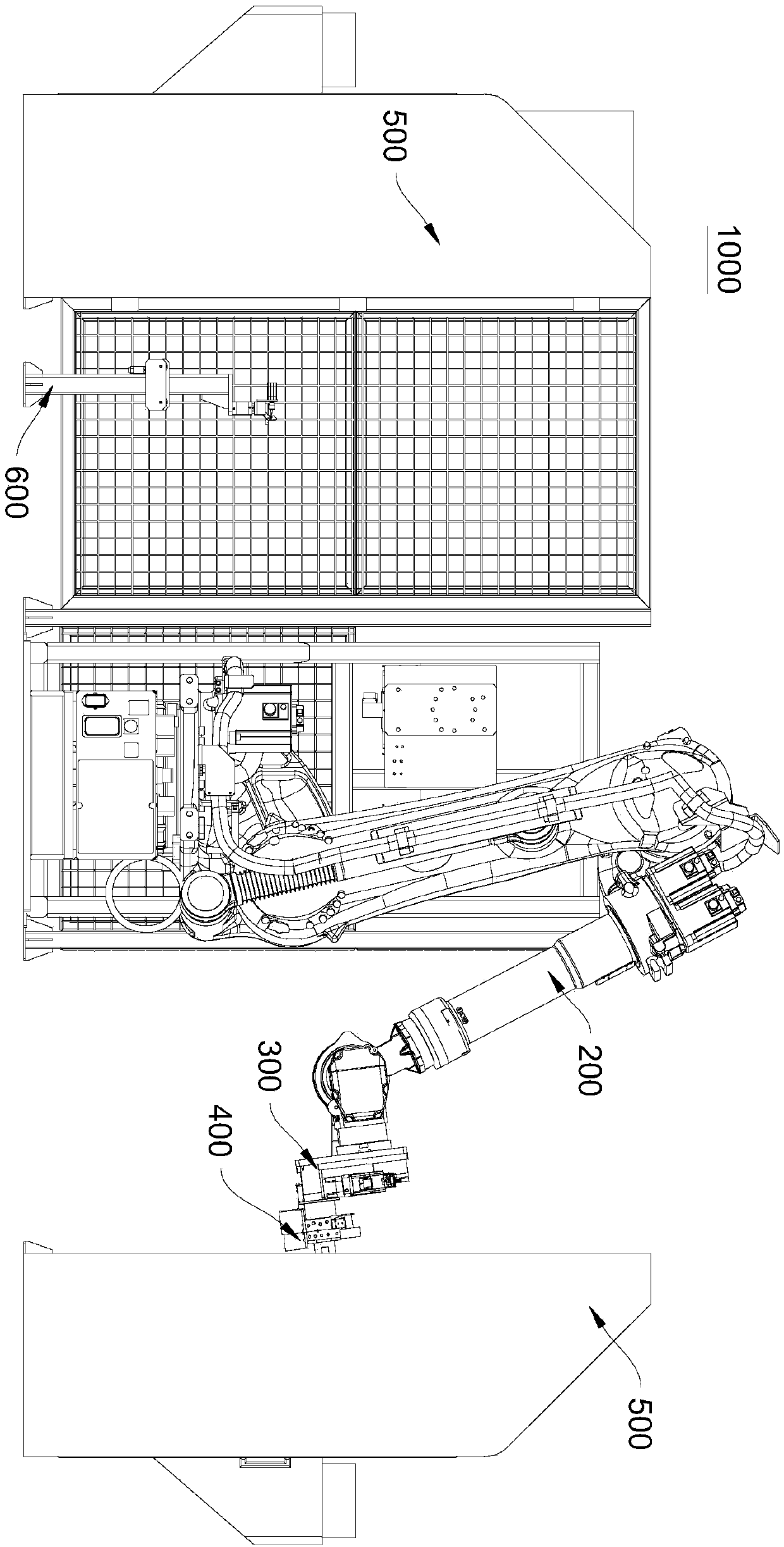

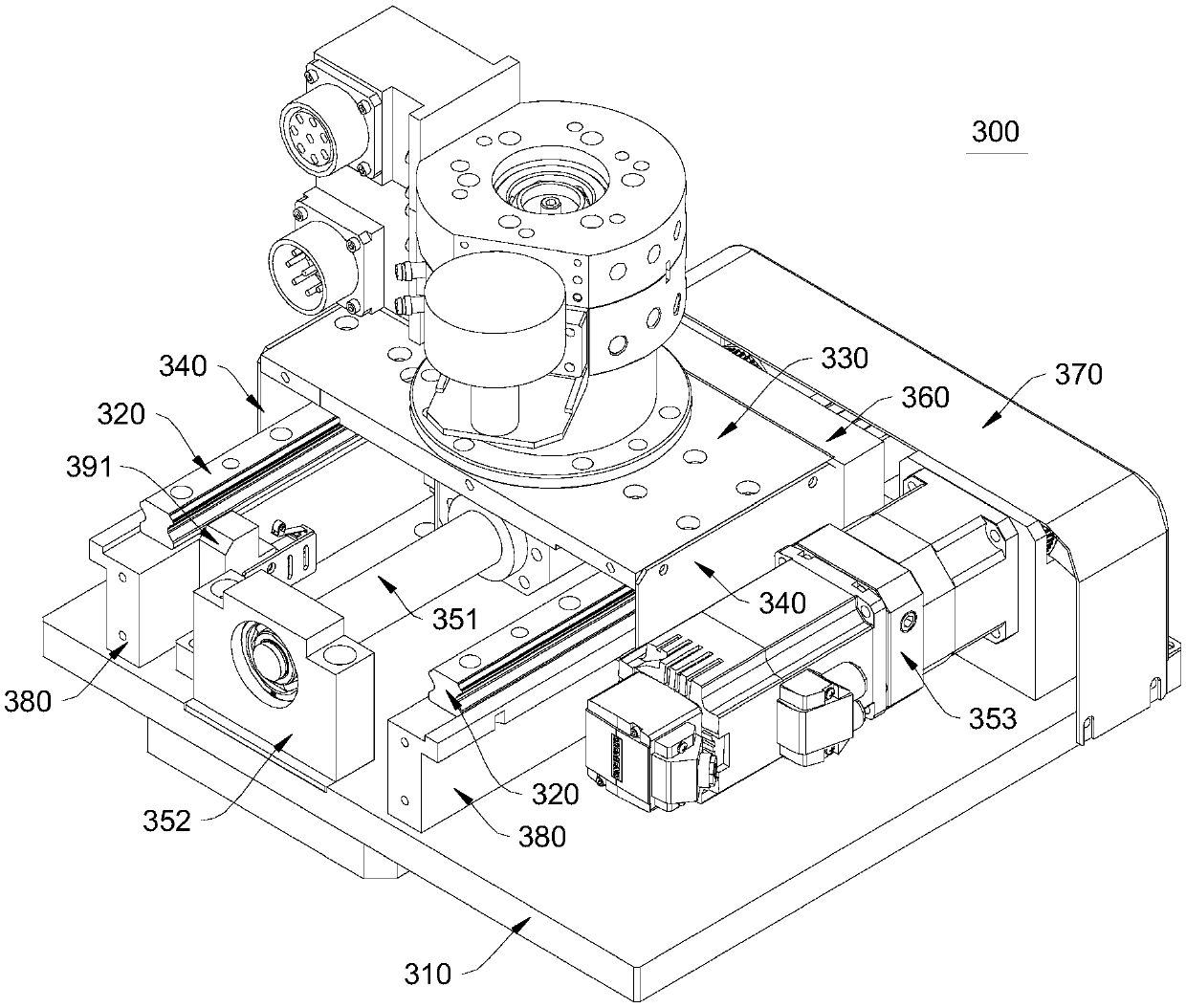

[0041] Please refer to Figure 1-11 , this embodiment provides a humanoid tool testing station 1000, which includes: a base (not shown in the figure), a mechanical arm 200, a tool feeding device 300, an angle grinder flexible fitting device 400 and a flat grinding platform 500. Both the mechanical arm 200 and the flat grinding platform 500 are fixedly connected to the base.

[0042] The flat grinding platform 500 includes: a grinding table 510 and a fixing block 560 for fixing the object 900 to be polished. A ring-shaped side wall protrudes from the periphery of the grinding table 510 , and the ring-shaped side wall and the bearing surface of the grinding table 510 enclose a grinding chamber 530 . The annular sidewall includes a first sidewall 521 and a second sidewall 522 oppositely arranged, and a third sidewall 523 and a fourth sidewall 524 oppositely arranged.

[0043] Both the first side wall 521 and the second side wall 522 are provided with a through-beam switch 540 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com