One-time grinding device and method for double-flange sides of short cylindrical inner ring

A technology of inner ring and cylinder, which is applied in the field of one-time grinding device for short cylindrical inner ring with double gears, can solve the problems of cost increase and achieve the effects of improved utilization rate, good grinding accuracy, and easy guarantee of grinding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

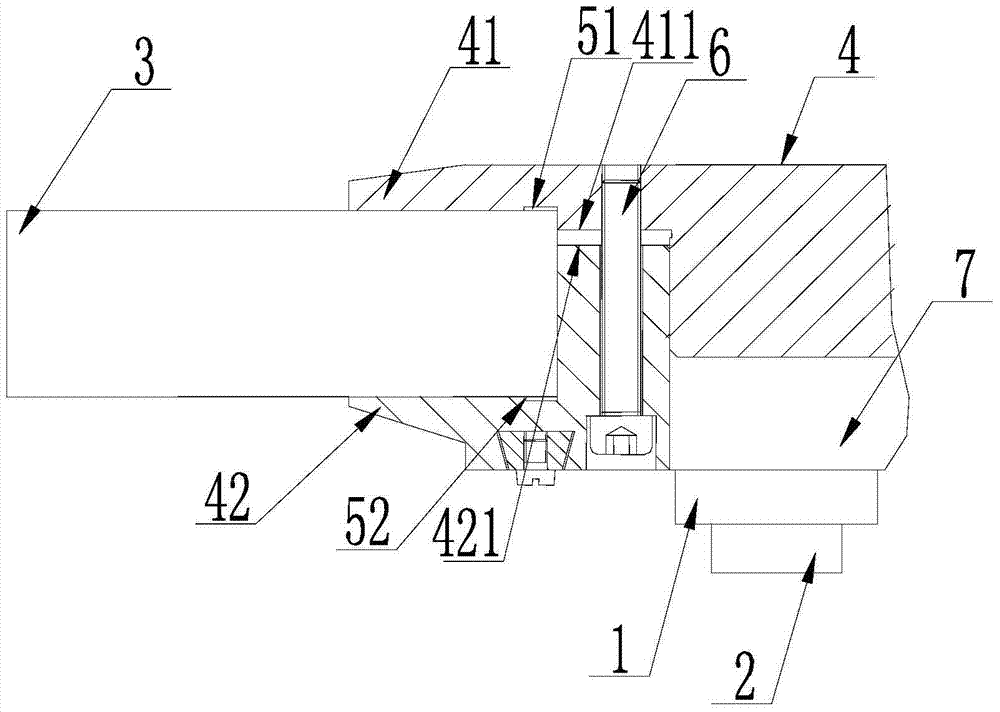

[0027] The structure of the primary grinding device for the double ribs of the short cylindrical inner ring in the embodiment of the present invention is as follows: image 3 As shown, it includes: an up and down driving device 1 , a left and right driving device 2 , a grinding wheel 3 and a grinding wheel mounting seat 4 .

[0028] The up and down driving device 1 is located on the grinding wheel mounting base 4, and is used to drive the grinding wheel mounting base 4 to move upward or downward, and then drive the grinding wheel 3 to move upward or downward. The up and down driving device 1 is but not limited to a linear motor, an air cylinder or an oil cylinder.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com