Numerical control grinder with double grinding wheels

A CNC grinding machine and double grinding wheel technology, applied in the direction of grinding machines, grinding workpiece supports, grinding/polishing equipment, etc., can solve the problems of large processing error deviation, increased production cost, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

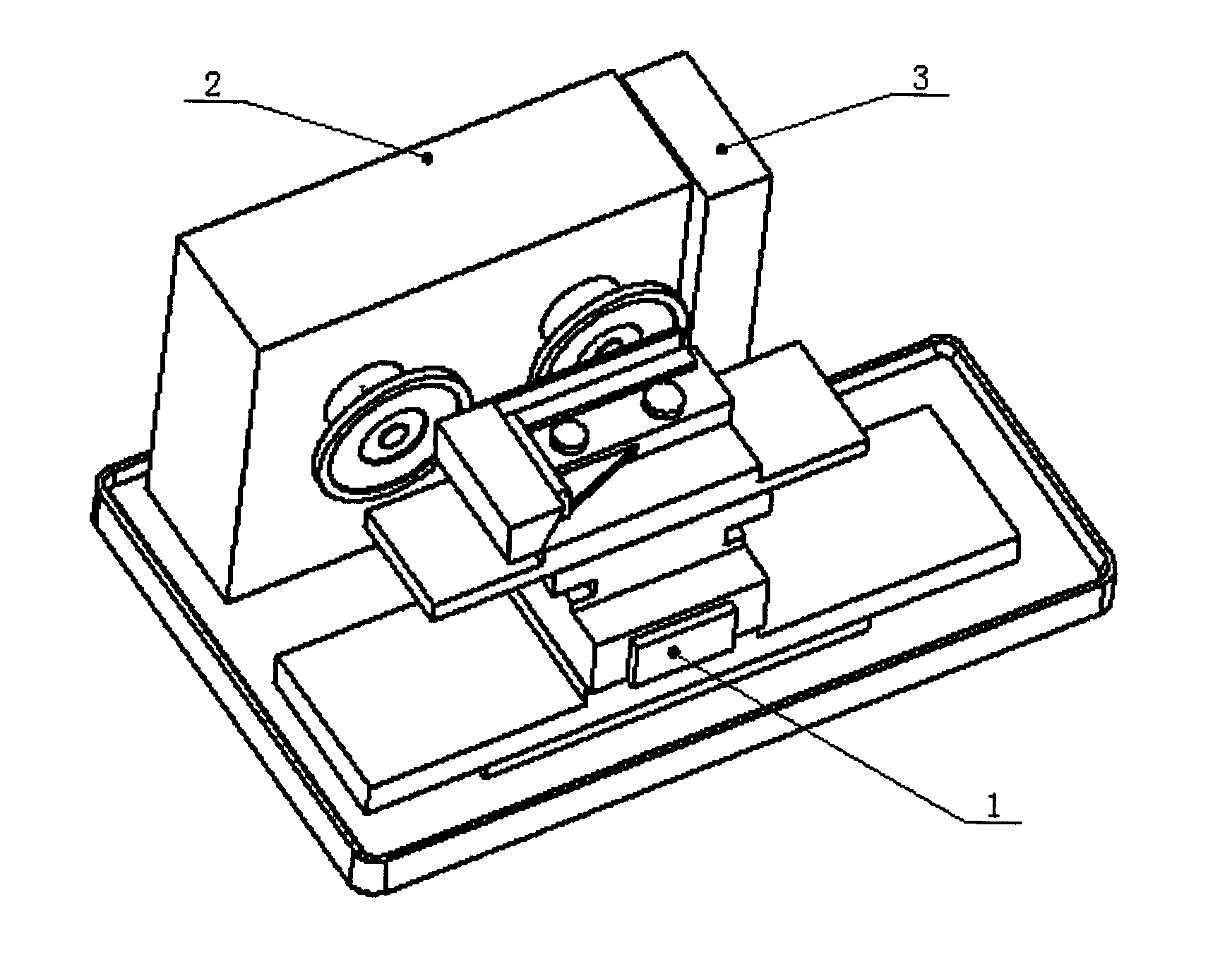

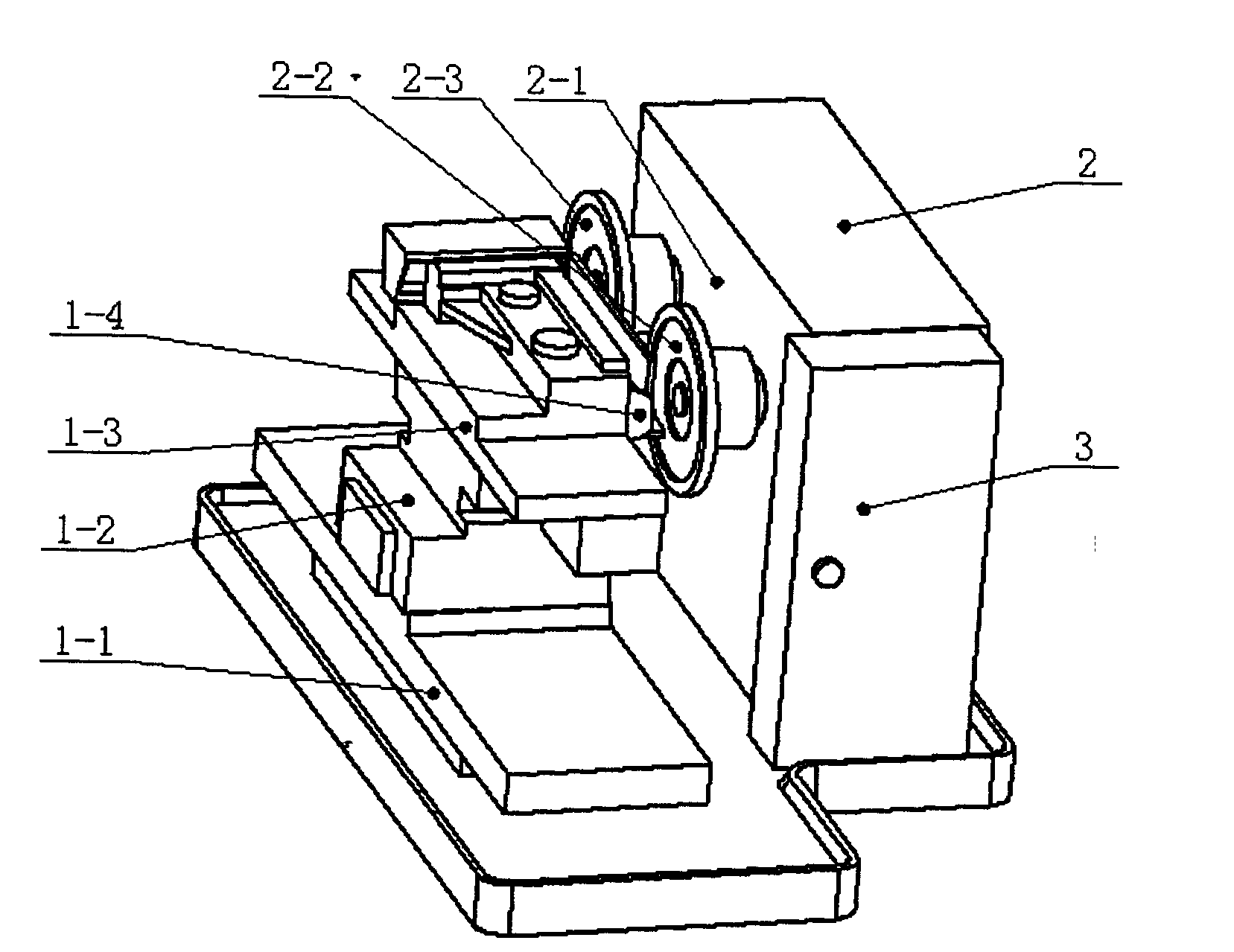

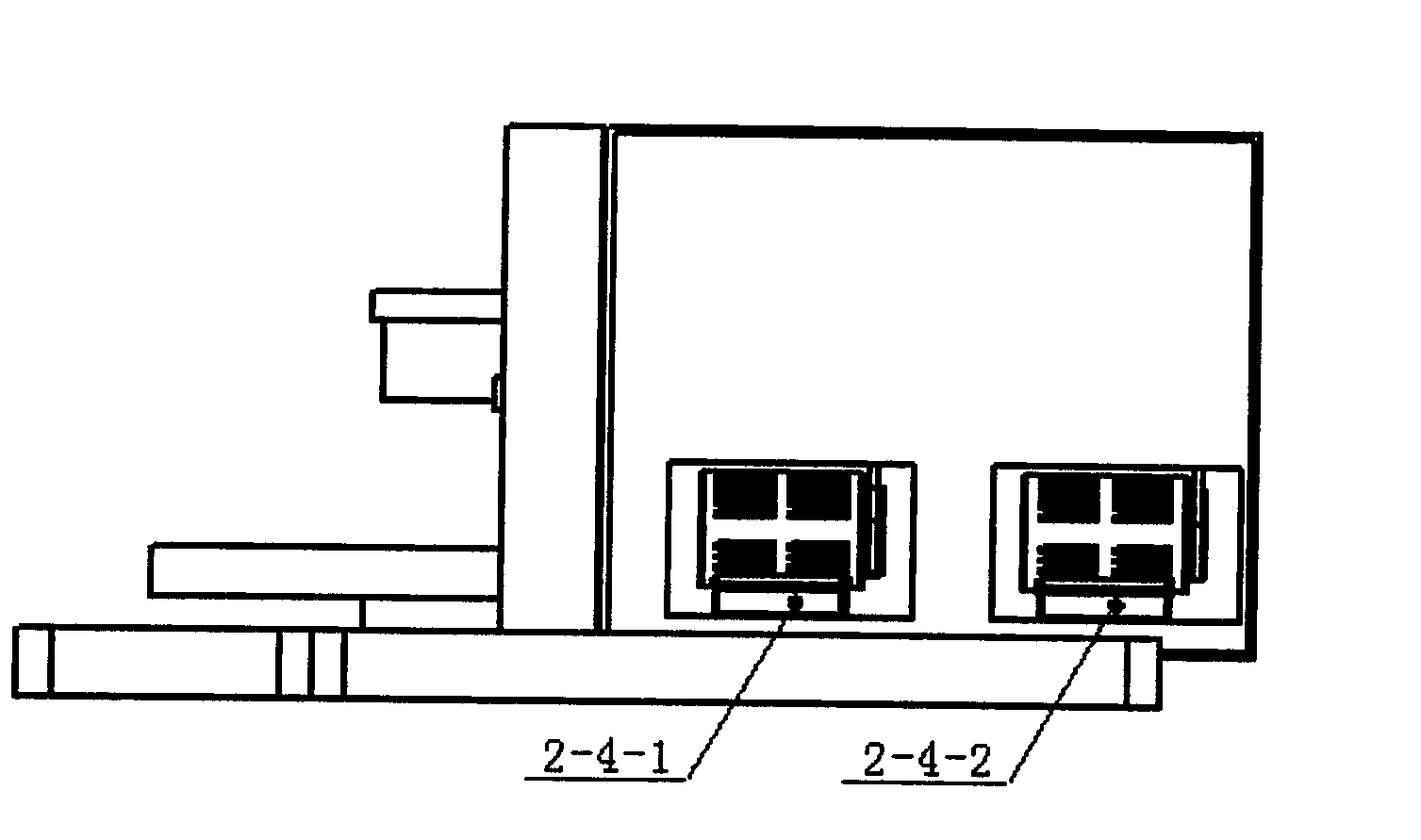

[0016] Embodiment 1: refer to Figure 1 to Figure 3 As shown, a double-grinding wheel CNC grinding machine includes a bed base, a grinding wheel mechanism, and a numerical control device, wherein, the fixed seat 2-1 of the grinding wheel mechanism 2 is respectively provided with a motor 2-4-1 and a main grinding wheel device 2 -2 and the motor 2-4-2 and the auxiliary grinding wheel device 2-3, the main grinding wheel device 2-2 or the auxiliary grinding wheel device 2-3 can operate independently or simultaneously, the control circuit of the grinding wheel mechanism 2 and the numerical control device 3-phase connection, the bed foundation 1 is provided with an A-axis general journey 1-1, a Z-axis general journey 1-2, an X-axis general journey 1-3, and a Y-axis general journey 1-4. The control circuits of the servo motors of the A axis, the Z axis, the X axis and the torque servo motor of the Y axis are all connected with the numerical control device 3 . The grinding wheel mech...

Embodiment 2

[0017] Embodiment 2: refer to Figure 4 As shown, the overall structure of the double grinding wheel CNC grinding machine is the same as that of Embodiment 1, the difference is that the main grinding wheel device 2-2 and the auxiliary grinding wheel device 2-3 of the grinding wheel mechanism 2 are installed independently.

Embodiment 3

[0018] Embodiment 3: refer to Figure 5 As shown, the overall structure of the double grinding wheel CNC grinding machine is the same as that of Embodiment 1. The difference is that the main grinding wheel device 2-2 and the auxiliary grinding wheel device 2-3 of the grinding wheel mechanism 2 can be used arbitrarily along the X axis. Direction parallel installation or vertical installation form.

[0019] The grinding workpieces of the present invention are generally parts with inclined surfaces and concave arc surface features, such as multiple concave arc surfaces or inclined surfaces on blades in various types of cutting tools. After the workpiece is clamped by the workbench, the main cutting movement of different processes is completed by the main grinding wheel device 2-2 and the auxiliary grinding wheel device 2-3. All feed movements are performed by bed base 1. Make the workpiece complete multi-process and multi-step processing under the condition of one clamping, ens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com