Abrasive material

A technology of abrasive particles and abrasive layers, applied in abrasives, electrical components, metal processing equipment, etc., can solve the problem of high grinding cost and achieve the effect of low grinding cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

[0032] Hereinafter, a first embodiment of the present invention will be described in detail with appropriate reference to the drawings.

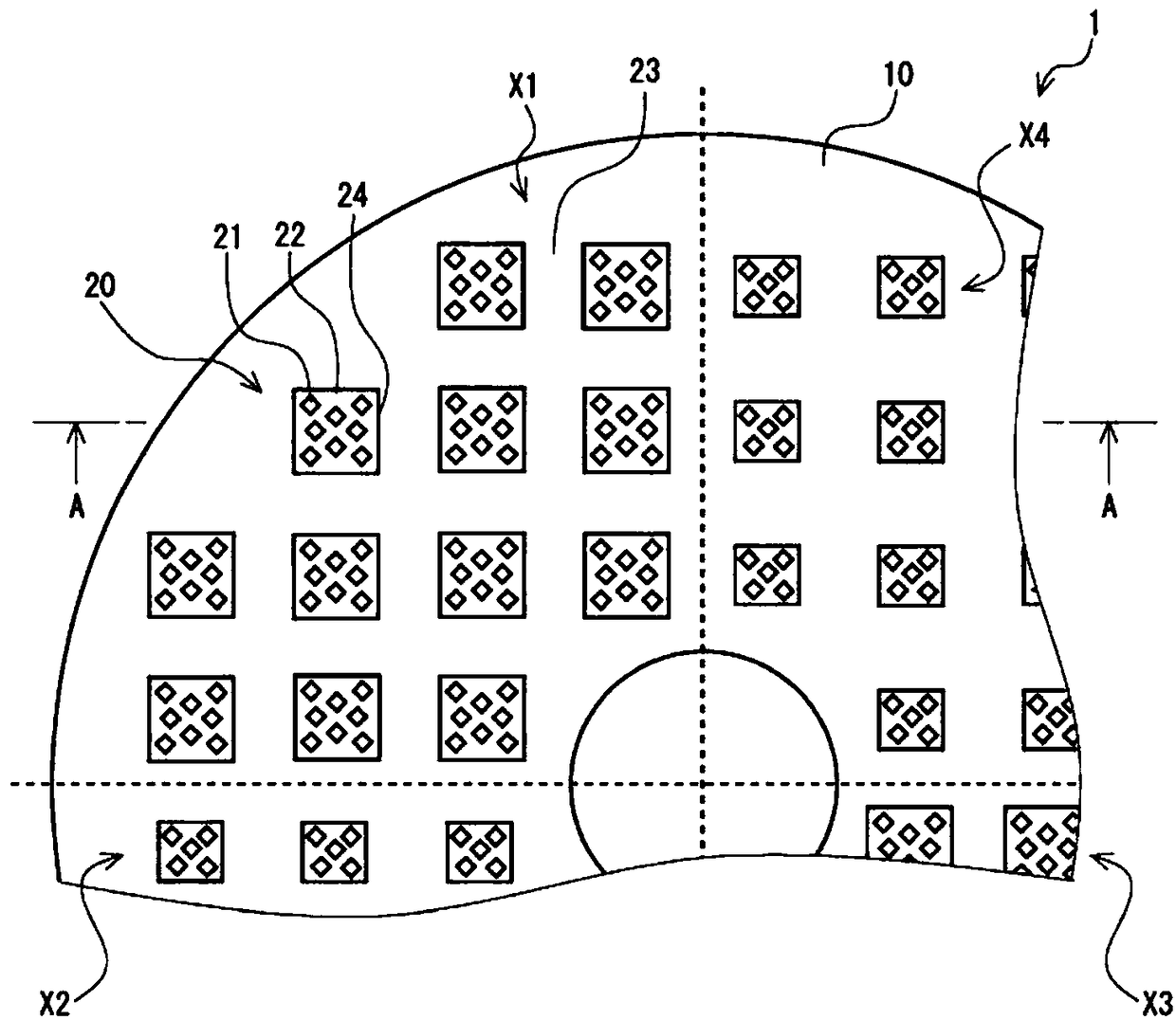

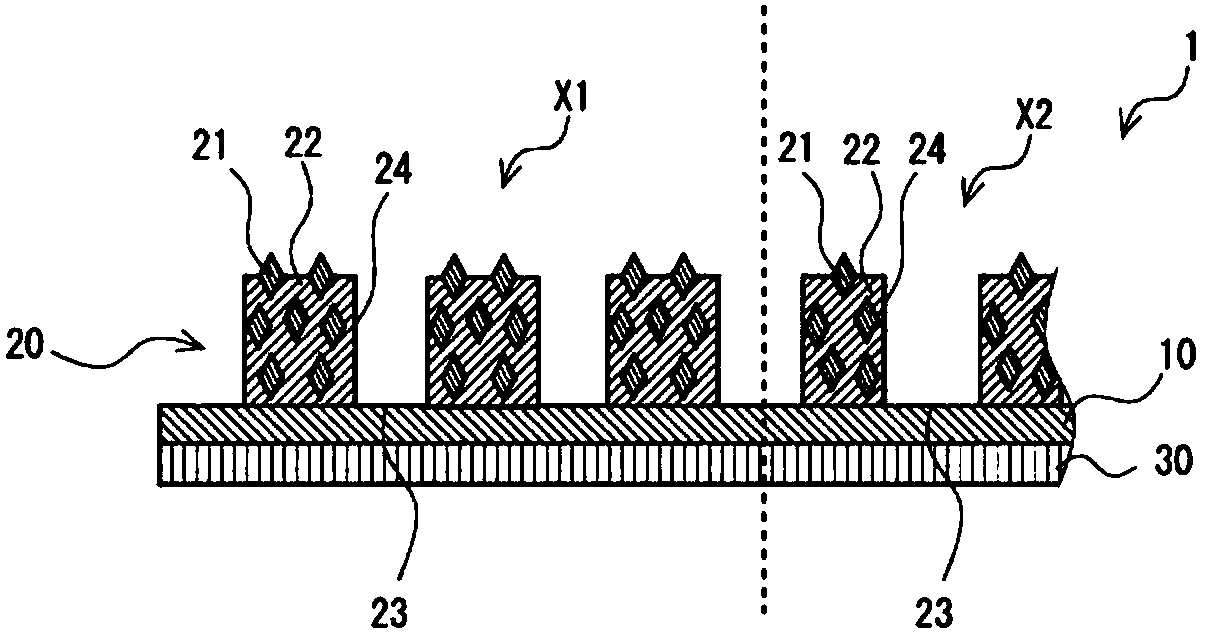

[0033]

[0034] Figure 1A and Figure 1B The abrasive material 1 shown is disc-shaped and mainly includes a base material 10 and an abrasive layer 20 laminated on the surface side of the base material 10 . In addition, the abrasive material 1 includes an adhesive layer 30 laminated on the back side of the base material 10 . The grinding material 1 is disposed on a grinding platen of a known grinding device, and is ground by the grinding device while rotating while contacting the object to be ground. That is, the grinding direction of the grinding material 1 is the circumferential direction of the substrate 10 .

[0035] (Substrate)

[0036] The base material 10 is a plate-shaped member for supporting the polishing layer 20 .

[0037] The material of the substrate 10 is not particularly limited, and examples include: polyethylene terep...

no. 2 Embodiment

[0093] Hereinafter, a second embodiment of the present invention will be described in detail with appropriate reference to the drawings.

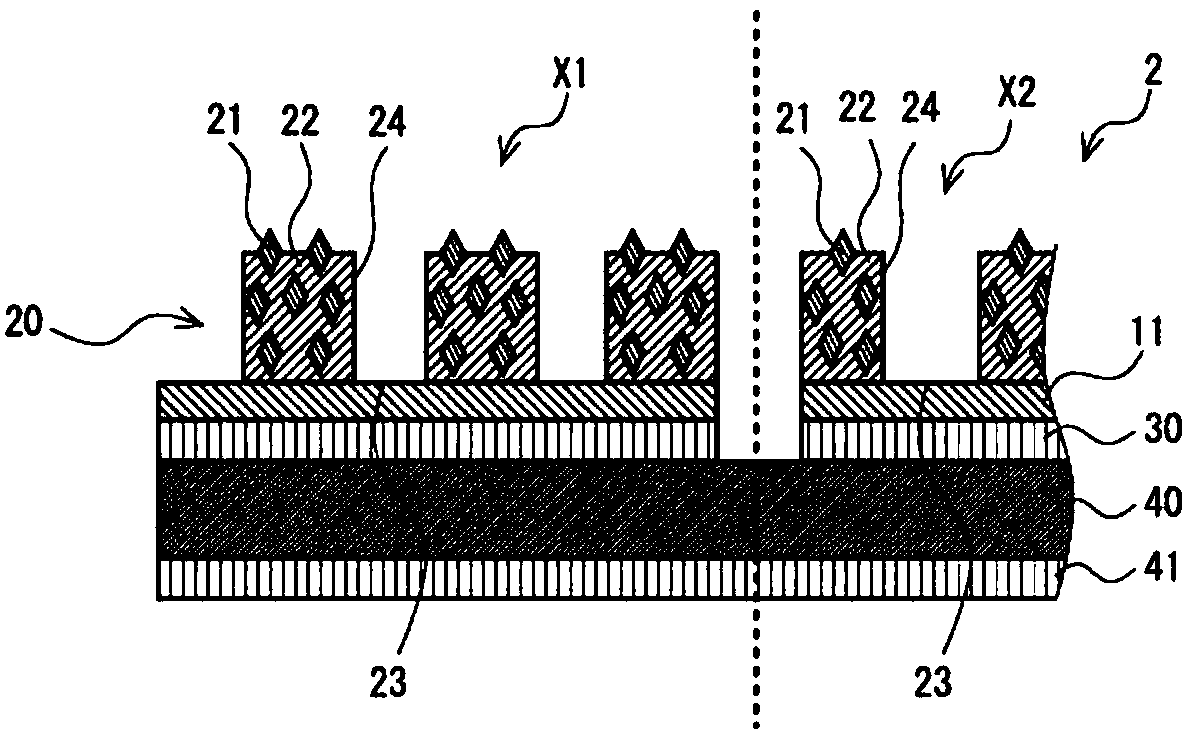

[0094] figure 2 The abrasive material 2 shown is disk-shaped, and mainly includes a base material 11 and an abrasive layer 20 laminated on the surface side of the base material 11 . In addition, the abrasive material 2 includes an adhesive layer 30 laminated on the back side of the base material 11 . Furthermore, the abrasive material 2 includes a support 40 laminated via an adhesive layer 30 and a support adhesive layer 41 laminated on the back side of the support 40 . In addition, the same code|symbol is attached|subjected about the same component as 1st Example, and description is abbreviate|omitted.

[0095] (Substrate)

[0096] The substrate 11 is a plate-shaped member for supporting the polishing layer 20 . The substrate 11 is divided into a first region X1, a second region X2, a third region X3, and a fourth region X4 along the ...

Embodiment 1

[0133] Diamond abrasive grains were prepared, and the average particle diameter was measured using "Microtrac MT3300EXII" manufactured by Nikkiso Co., Ltd. The average particle size of the diamond abrasive grains is 44 μm. Furthermore, the type of diamond in the abrasive grains is treated diamond coated with 55% by mass nickel.

[0134] Sodium silicate (No. 3 sodium silicate) as binder, the diamond abrasive grains, and alumina (Al 2 o 3 , with an average particle size of 12 μm) were mixed and prepared so that the content of the diamond abrasive grains relative to the abrasive layer became 5 vol % and the content of the filler relative to the abrasive layer became 71 vol % to obtain a coating liquid.

[0135] A disc-shaped aluminum plate having an average thickness of 300 μm, an outer diameter of 386 mm, and an inner diameter of 148 mm was prepared as a base material. Divided into 8 regions by 4 straight lines passing through the center of the substrate surface and forming a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com