Clamping device capable of being used for improving grinding precision of shaft parts

A technology of clamping device and shaft parts, which is applied in the direction of grinding workpiece supports, etc., can solve the problems of uncontrollable precision of grinding processing, difficult centering adjustment of thimble holes, and difficult control of grinding precision, so as to improve grinding Accuracy, reduce scrap rate, and facilitate the effect of clamping alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

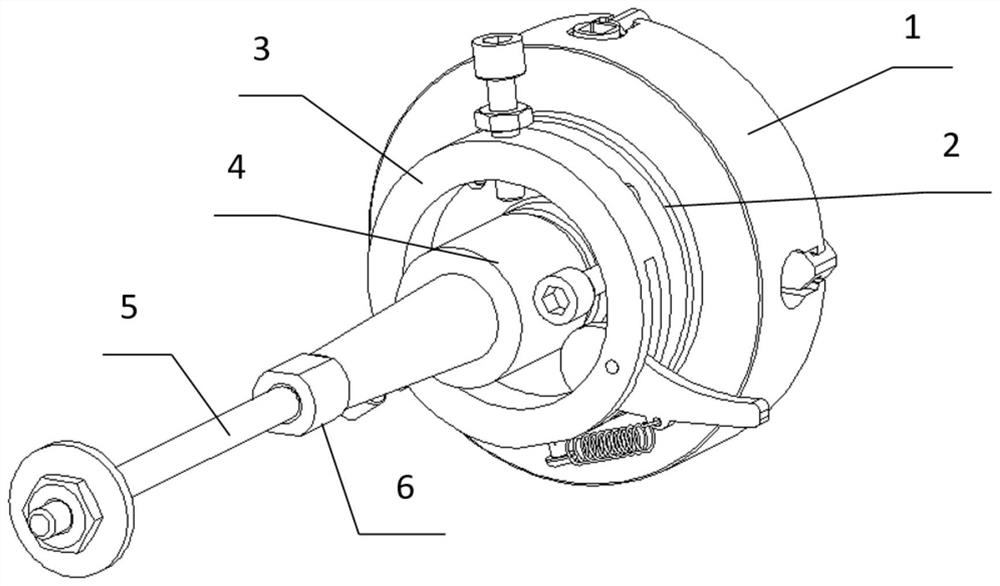

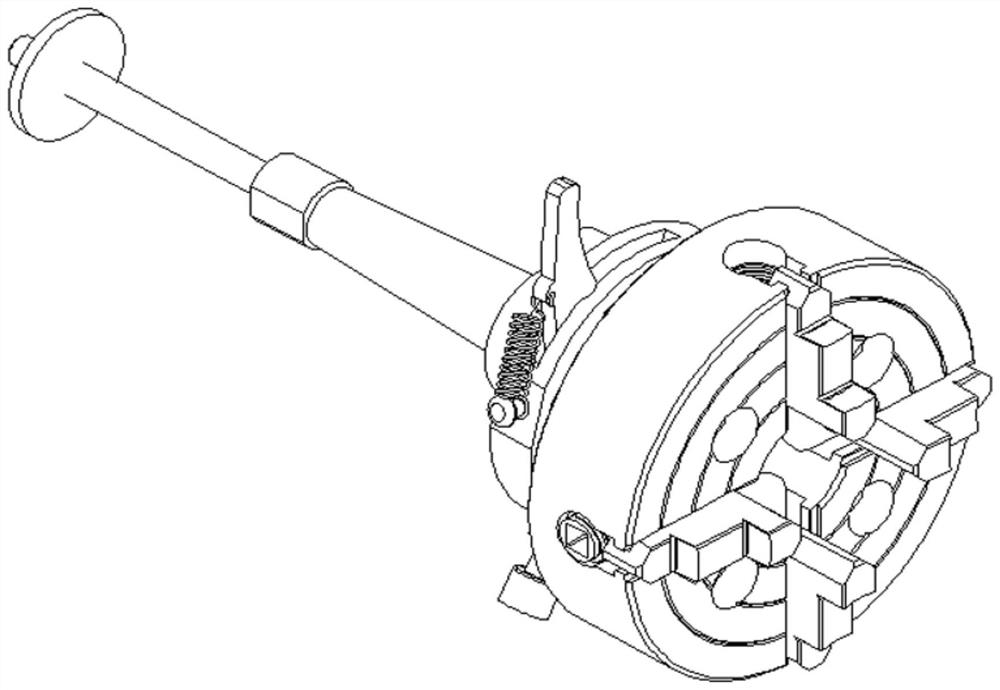

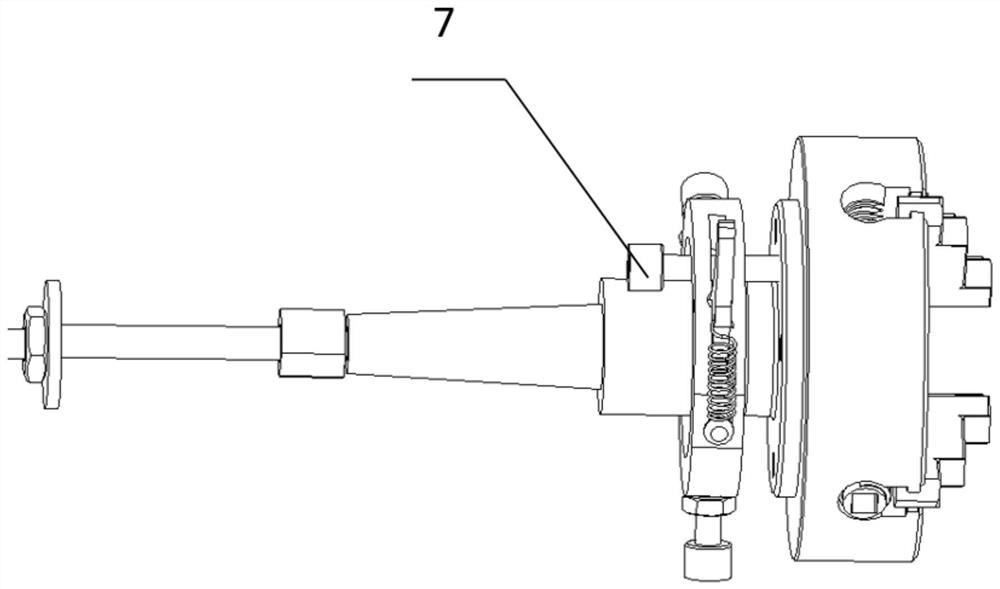

[0033] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

[0034] It should be understood that the appended drawings are not to scale, presenting a suitably simplified representation of various features illustrative of the basic principles of the invention. The specific design features of the invention disclosed herein, including, for example, specific dimensions, orientations, locations and shapes will be determined in part by the particular intended application and use environment.

[0035] In the accompanying figures, the same or equivalent parts (elements) are designated with the same reference numerals.

[0036] In the description of the present invention, it should be noted that the terms "center", "longitudinal", "transverse", "upper", "lower", "front", "rear", "left", "right", " The orientations or positional relationships indicated by "vertical", "horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com