Turbine blade digital control abrasive belt grinding machine and operating method thereof

A technology for steam turbine blades and abrasive belt grinders, which is used in abrasive belt grinders, grinders, and parts of grinding machine tools.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

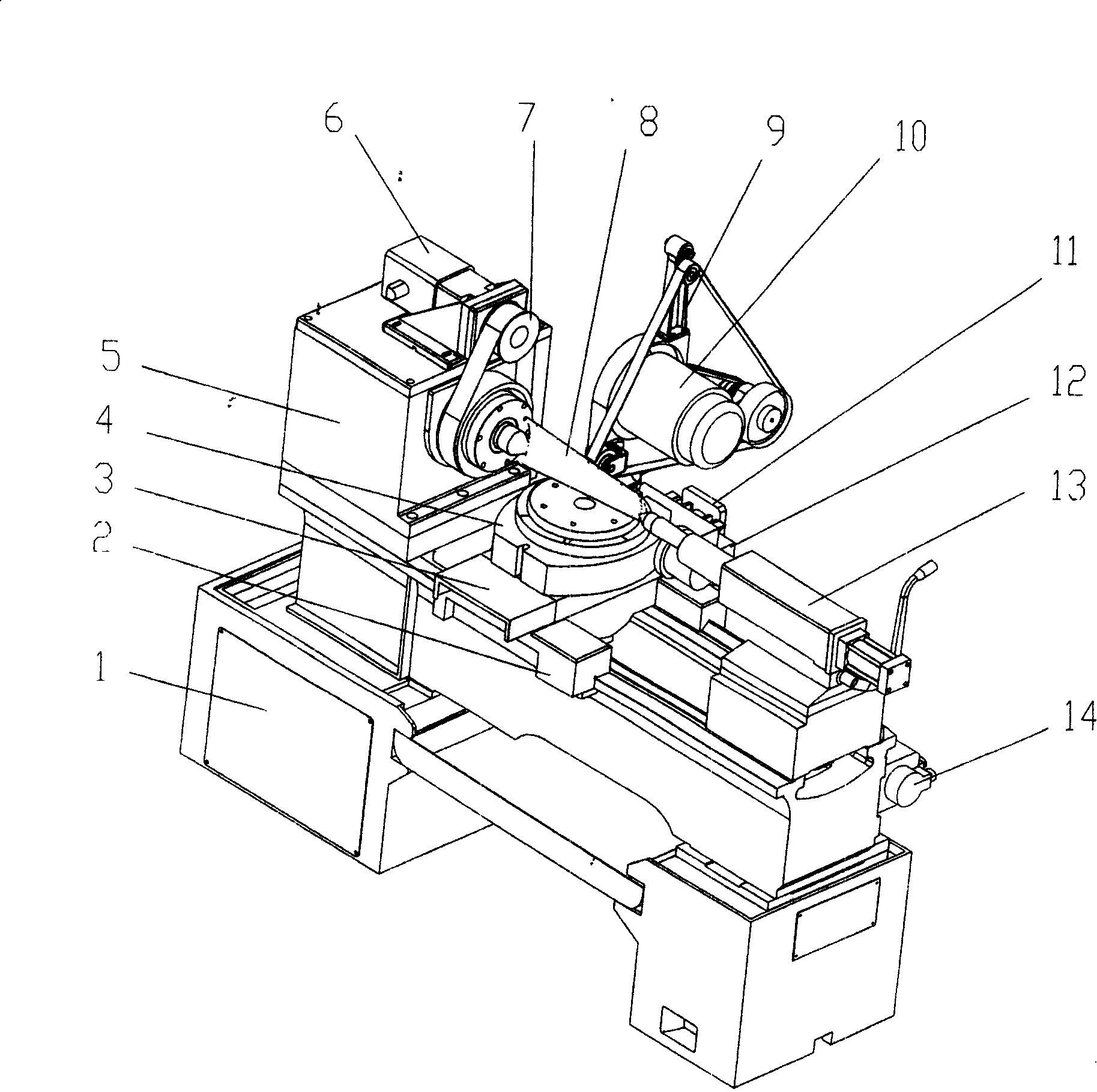

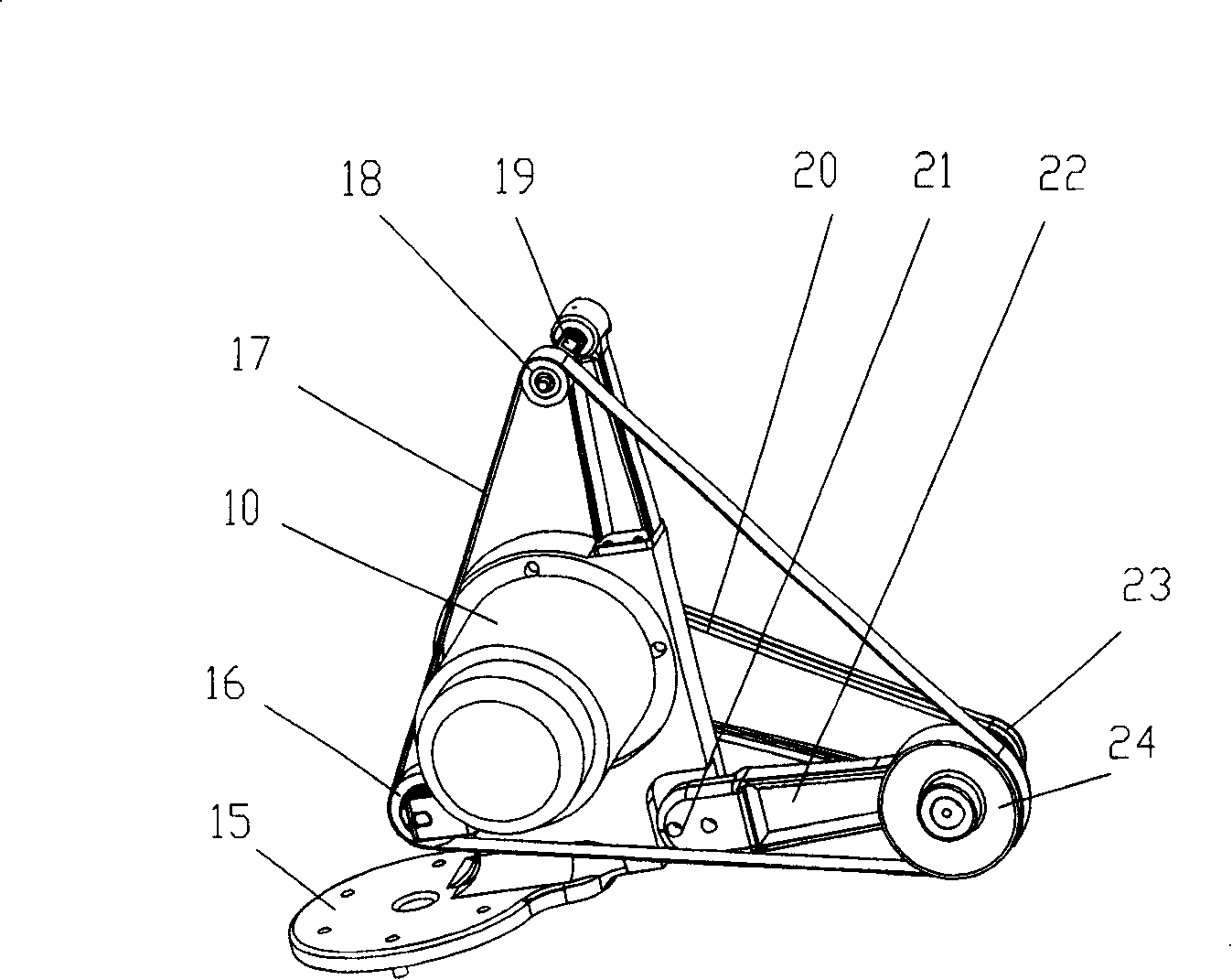

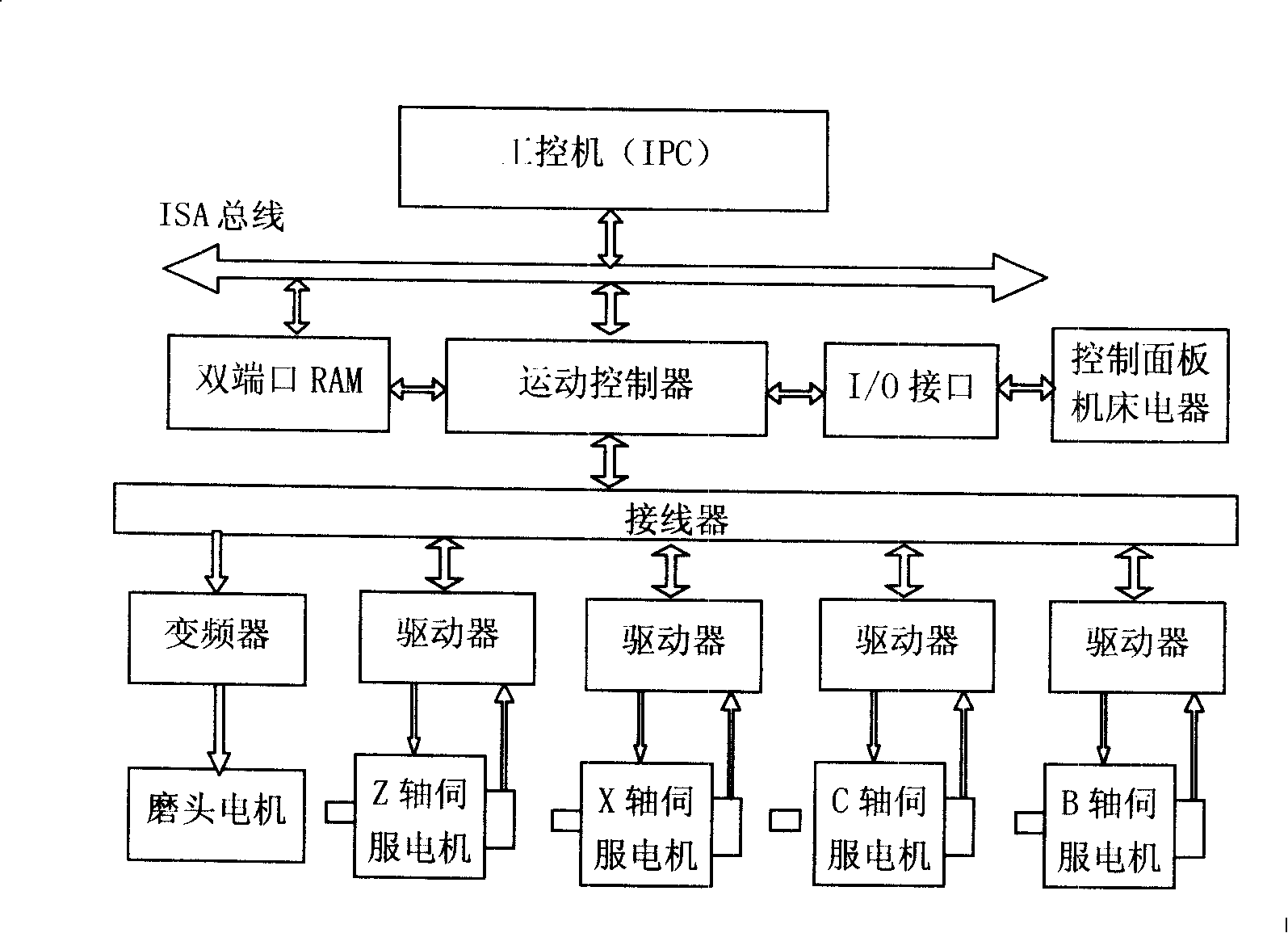

[0022] The invention includes a machine tool bed 1, a head frame 5, a tailstock 13, a large carriage 2, a small carriage 3, a rotary table 4, an abrasive belt grinding head 9, an open numerical control system and a motor for respectively driving five control axes of the machine tool , the steam turbine blade 8 is installed between the machine tool head frame 5 and the top of the tailstock 13, and is driven by the C-axis servo motor 6 to realize the rotational movement of the blade 8; the Z-axis servo motor 14 drives the large carriage 2, and thereby drives the abrasive belt The grinding head 9 performs longitudinal grinding and feeding motion of the blade 8 along the guide rail of the machine tool; the X-axis servo motor 11 drives the small carriage 3, and thus drives the abrasive belt grinding head 9 along the dovetail guide of the large carriage 2 to make the radial direction of the blade 8 Feeding movement; the B-axis servo motor 12 drives the turntable 4 to rotate around it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com