Adhesive sheet

A technology of adhesive sheets and adhesives, which is applied in the direction of adhesive types, hydrocarbon copolymer adhesives, adhesives, etc., and can solve problems such as insufficient fixation of the ground object, heavy peeling, and residual glue. , to achieve the effect of excellent fixation and low pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

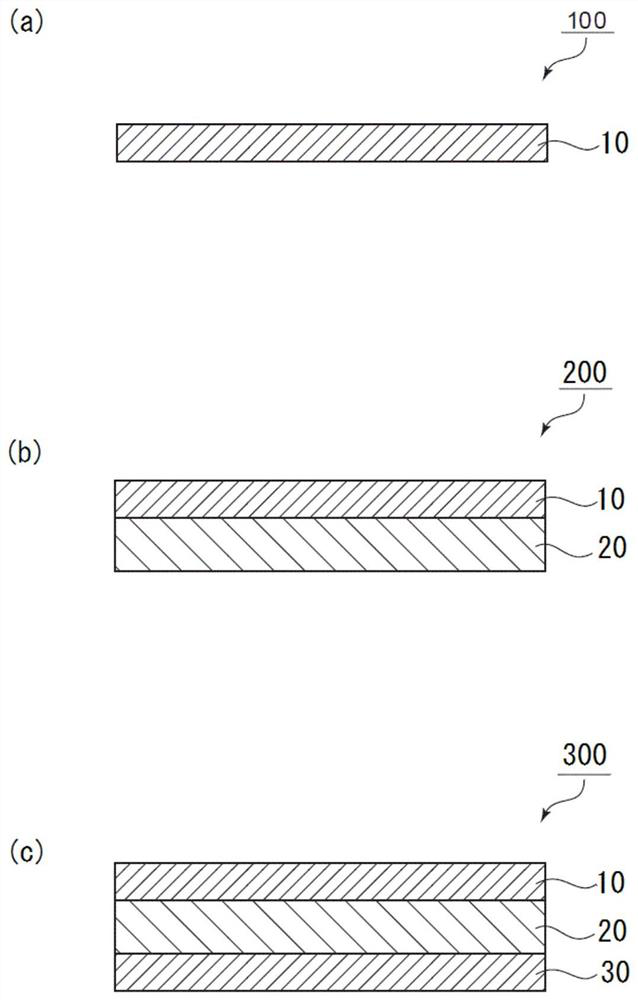

Image

Examples

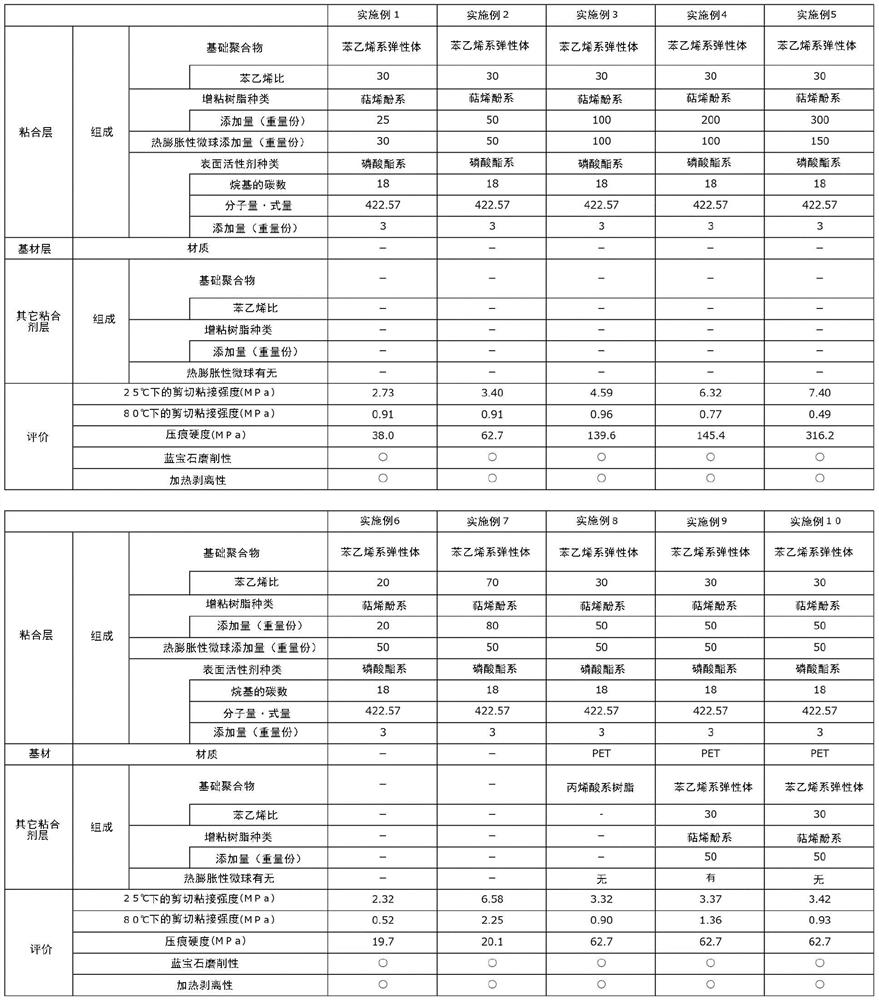

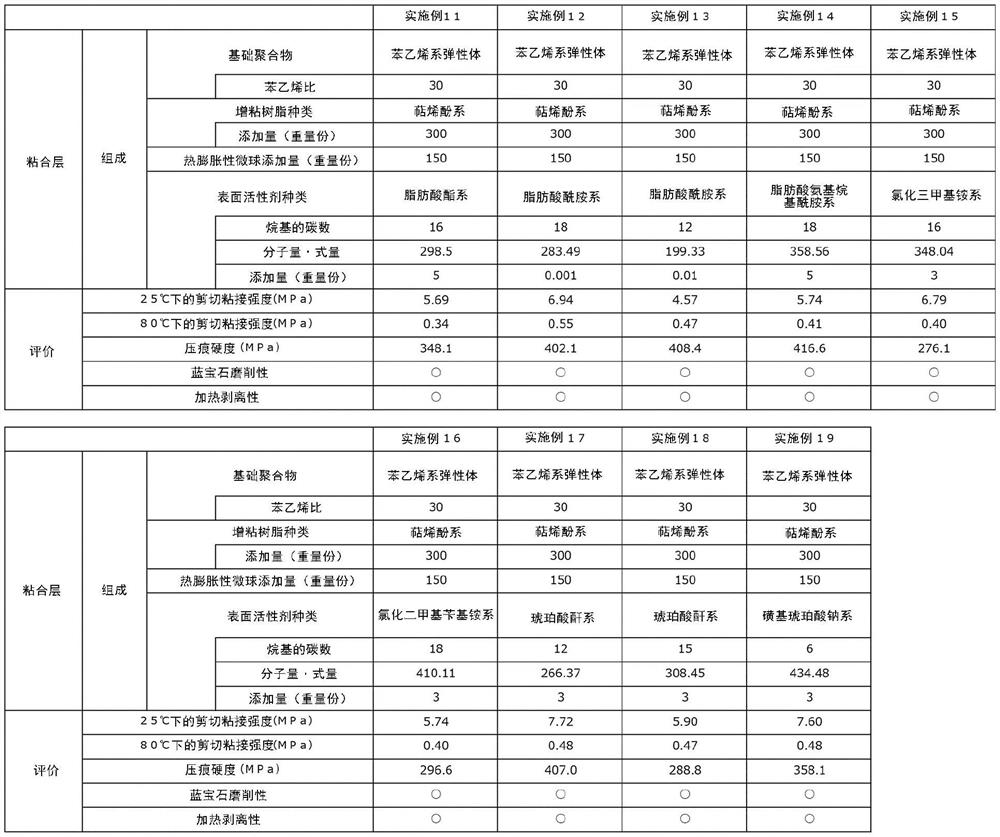

Embodiment 1

[0129] Maleic acid modified styrene·ethylene·butylene·styrene block copolymer (a) (SEBS: styrene part / ethylene·butylene part (weight ratio) = 30 / 70, acid value: 10 (mg -CH 3 ONa / g), Asahi Kasei Chemical Co., Ltd., trade name "Tuftec M1913") 100 parts by weight, terpene phenolic tackifier resin (YASUHARA CHEMICAL CO., LTD., trade name "YS Polystar T80") 25 parts by weight , 3 parts by weight of an epoxy-based crosslinking agent (manufactured by Mitsubishi Gas Chemical Co., Ltd., trade name "TETRAD-C"), heat-expandable microspheres (manufactured by Matsumoto Yushi Pharmaceutical Co., Ltd., trade name "Matsumoto Microsphere F-50D"), foaming Initial temperature 120° C., average particle diameter 14 μm) 30 parts by weight, phosphate-based surfactant (manufactured by Toho Chemical Industry Co., Ltd., trade name “Phosphamol RL210”, molecular weight 422.57, chemical formula: C 22 h 47 o 5 P, carbon number of the alkyl group: 18) 3 parts by weight, and toluene as a solvent were mixe...

Embodiment 2~5

[0132] A pressure-sensitive adhesive sheet was obtained in the same manner as in Example 1 except that the added amounts of the tackifier resin and thermally expandable microspheres were the amounts shown in Table 1. The obtained pressure-sensitive adhesive sheet was subjected to the above evaluations (1) to (4). The results are shown in Table 1.

Embodiment 6

[0134] Instead of the maleic acid-modified styrene-ethylene-butylene-styrene block copolymer (a), a maleic acid-modified styrene with a styrene moiety / ethylene-butene moiety (weight ratio) of 20 / 80 was used ·Ethylene·butylene·styrene block copolymer (b) (acid value: 10(mg-CH 3ONa / g), manufactured by Asahi Kasei Chemical Co., Ltd., trade name "Tuftec M1943"), the addition amount of the tackifying resin and thermally expandable microspheres is set to the amount shown in Table 1, except that, the same operation as in Example 1 , to obtain an adhesive sheet. The obtained pressure-sensitive adhesive sheet was subjected to the above evaluations (1) to (4). The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com