Stirring ball mill

一种搅拌式球磨、搅拌轴的技术,应用在谷物处理等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

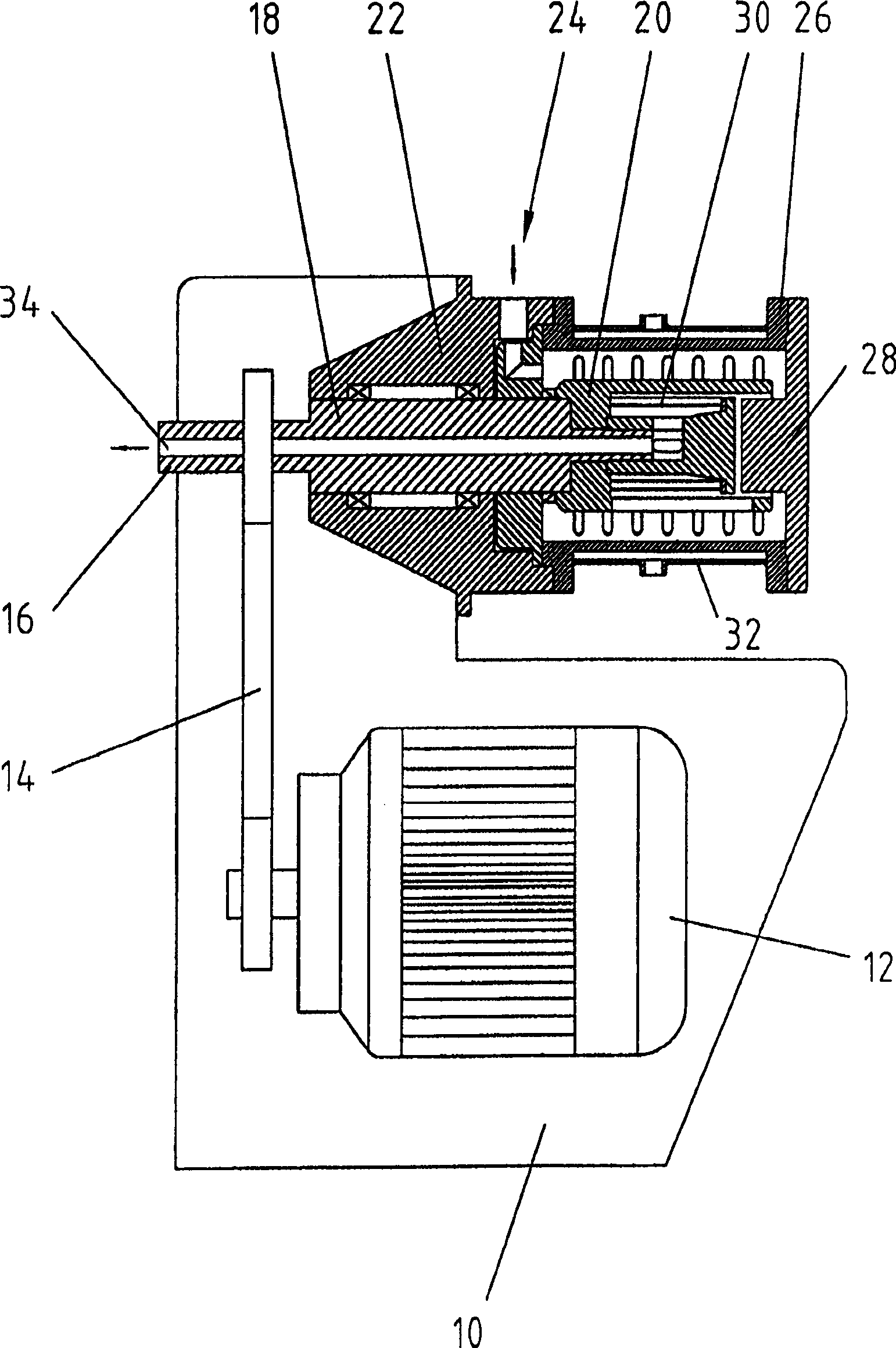

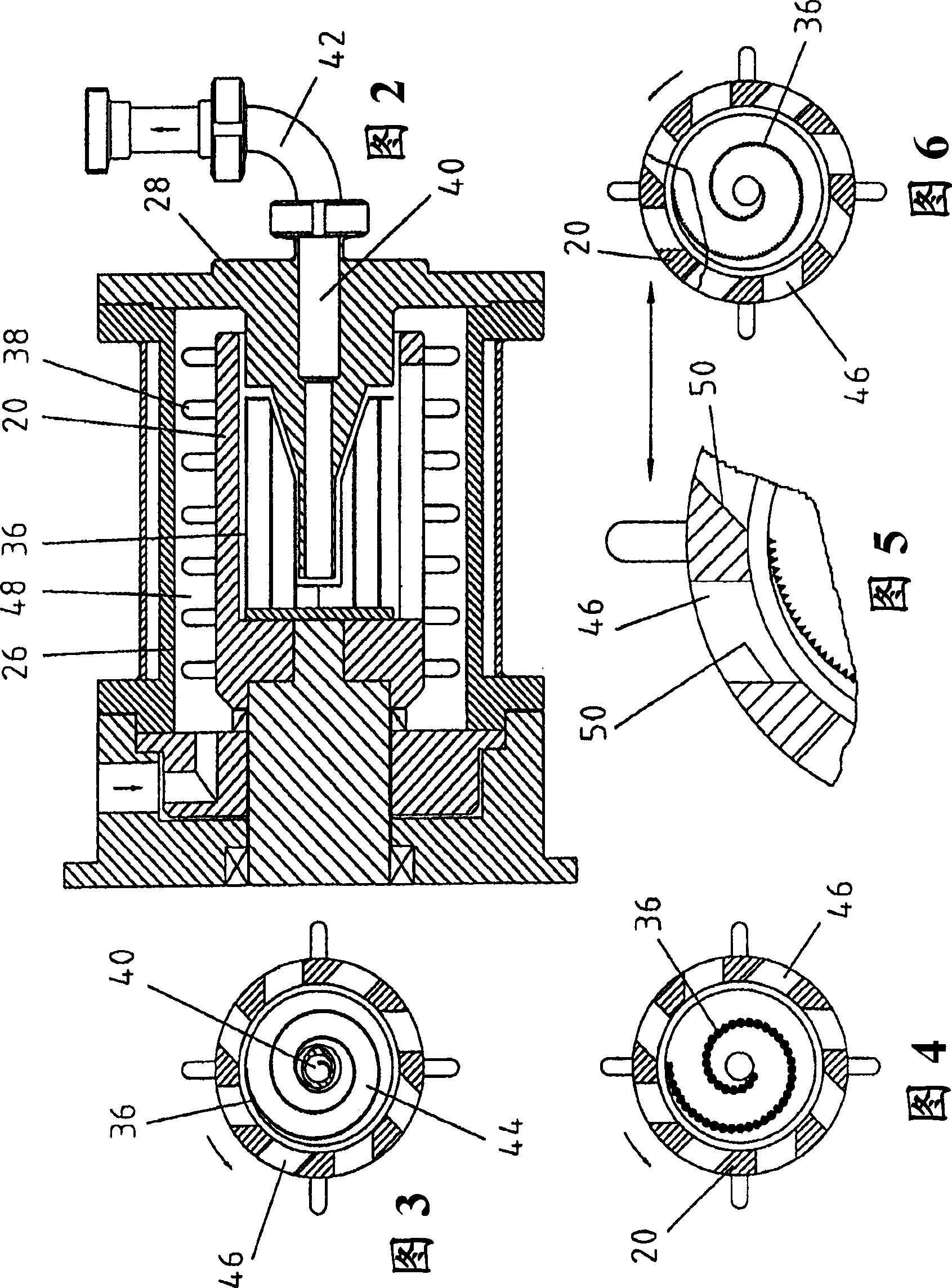

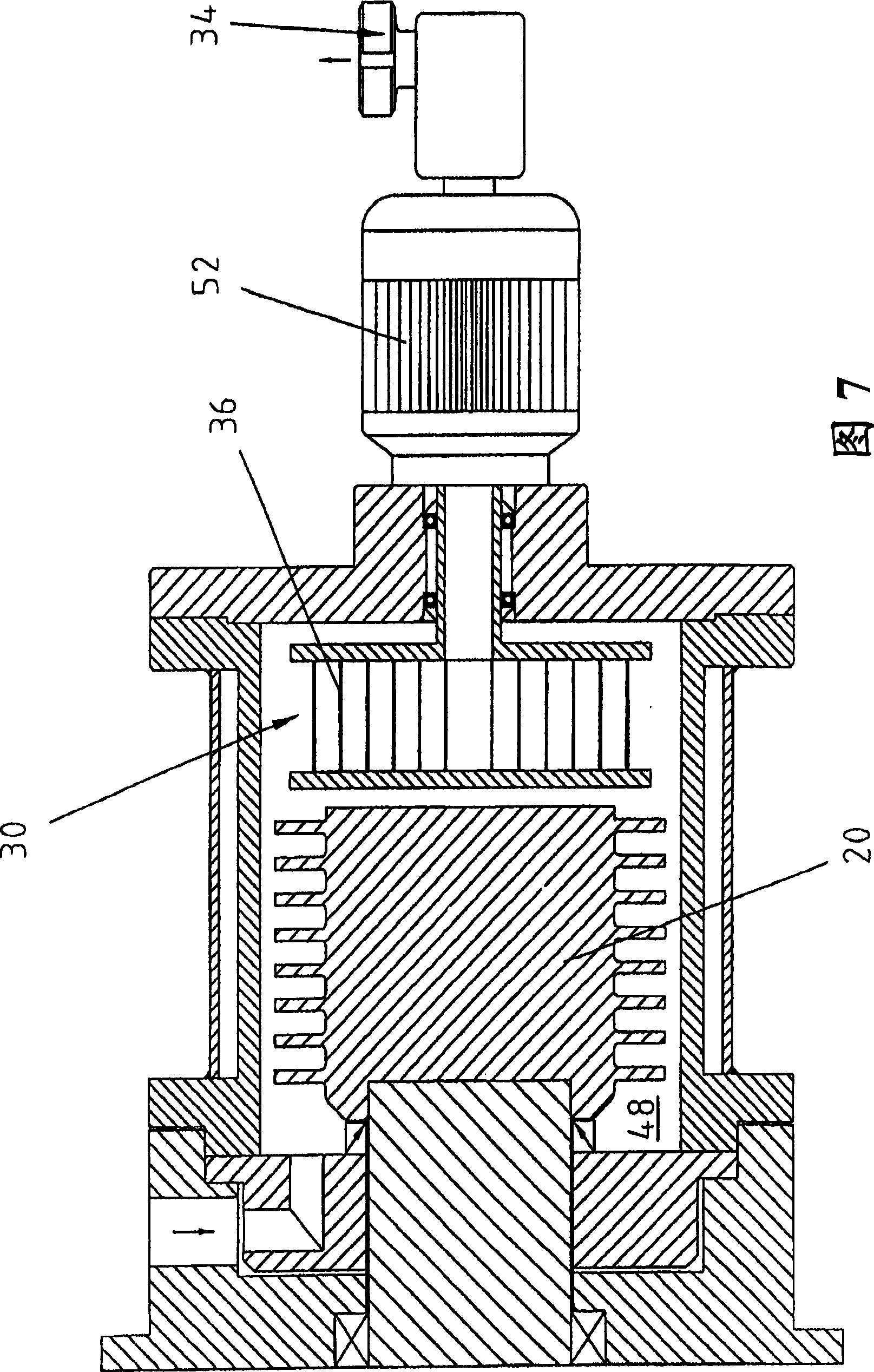

[0081] The agitating ball mill of the present invention consists of a housing 10 in which a driving device 12 in the form of an electric motor is arranged. The drive unit is connected to a drive shaft 16 via a drive belt 14 . The drive shaft transitions into a bearing shaft 18 , which is in turn connected to the stirring shaft 20 . The abrasive material inlet 24 is located on the upper side of the bearing housing 22 . The grinding chamber 48 is surrounded by the grinding container 26, which surrounds the stirring shaft 20 and the bottom surface 28 of the grinding container; In order to cool or heat the grinding container, the grinding container is surrounded by a cooling or heating outer casing 32 , forming a double-layer structure. The ground material leaves the grinding vessel through the central outlet, which starts from the agitator shaft, passes through the bearing shaft until it reaches the drive shaft. Fig. 2 shows the arrangement of spiral 36, and this spiral is pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com