Rail switching device for electric control switch

A turnout and track technology, applied in the field of track switch devices controlled by electric drivers, can solve problems such as small torque, difficult realization, and large current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

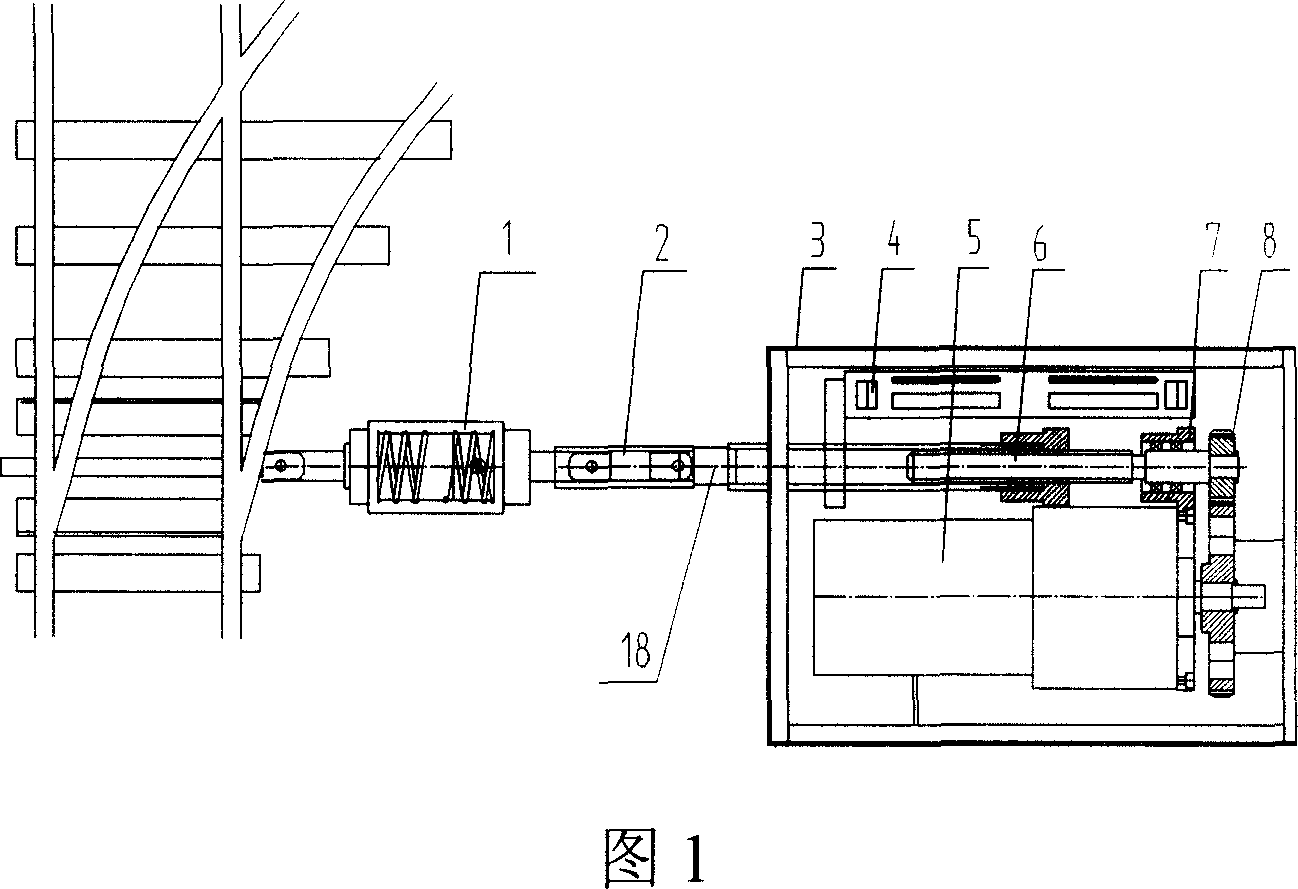

[0024] Embodiment 1: The track switch machine has an electric controller and a pusher, and the electric controller is connected with the track through the pusher.

[0025] The electric controller has a power machine and a push rod, and the power machine is connected with the push rod.

[0026] Described power machine has box body 3, and in box body 3, motor 5, travel switch 4, thread pair 6, gear pair 8 and frame 7 are arranged, and travel switch is positioned at one side in the box body, and motor is positioned at the other side in the box body. On the side, there is a threaded pair between the limit switch and the motor, the shaft of the threaded pair is connected to the frame, one end of the shaft of the threaded pair is connected to the push rod, the other end is connected to the gear pair, and the driving wheel of the gear pair is connected to the motor.

[0027] The pusher has a breakout buffer 1, and the breakout buffer has a cover with a spring in the cover, and a conn...

Embodiment 2

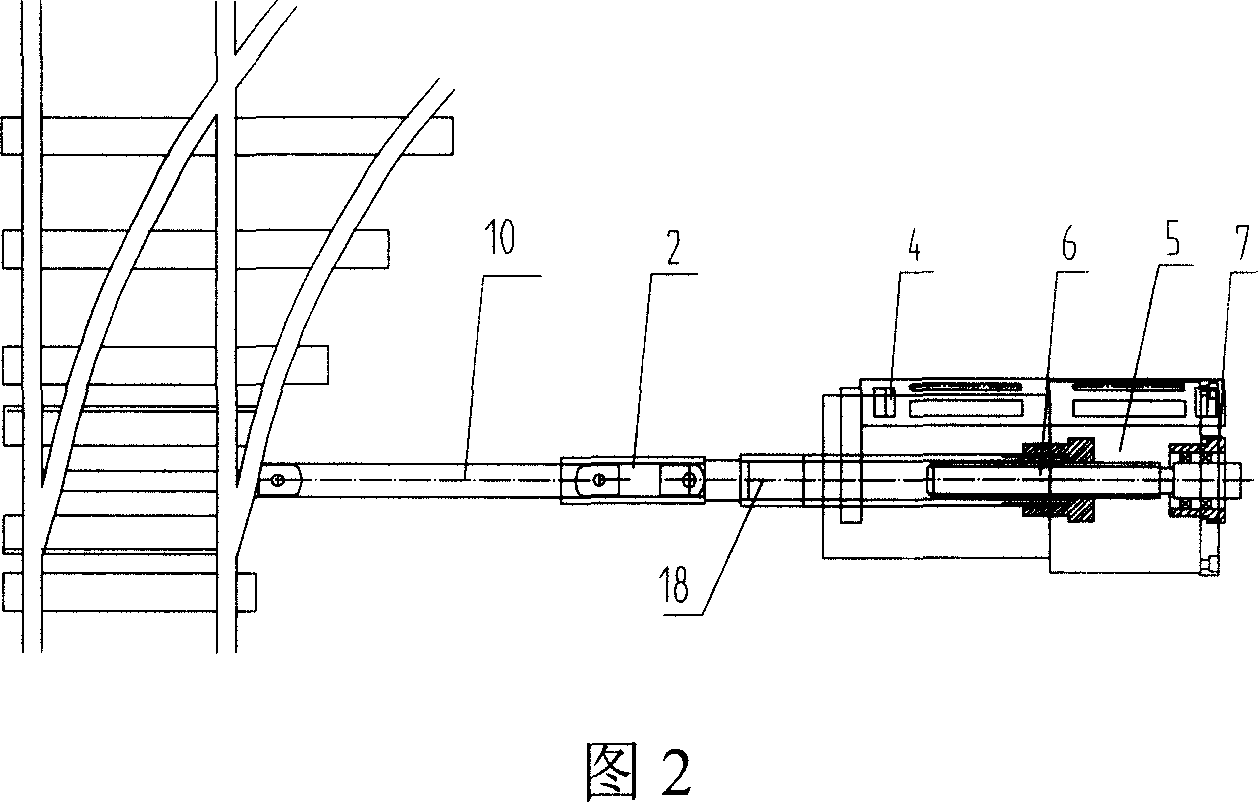

[0028] Embodiment 2: The power machine described is the vertical structure of the power machine in Embodiment 1, the pusher is the connecting rod 19, and the push rod is connected with the track through the connecting rod. Others are the same as in Example 1. slightly.

Embodiment 3

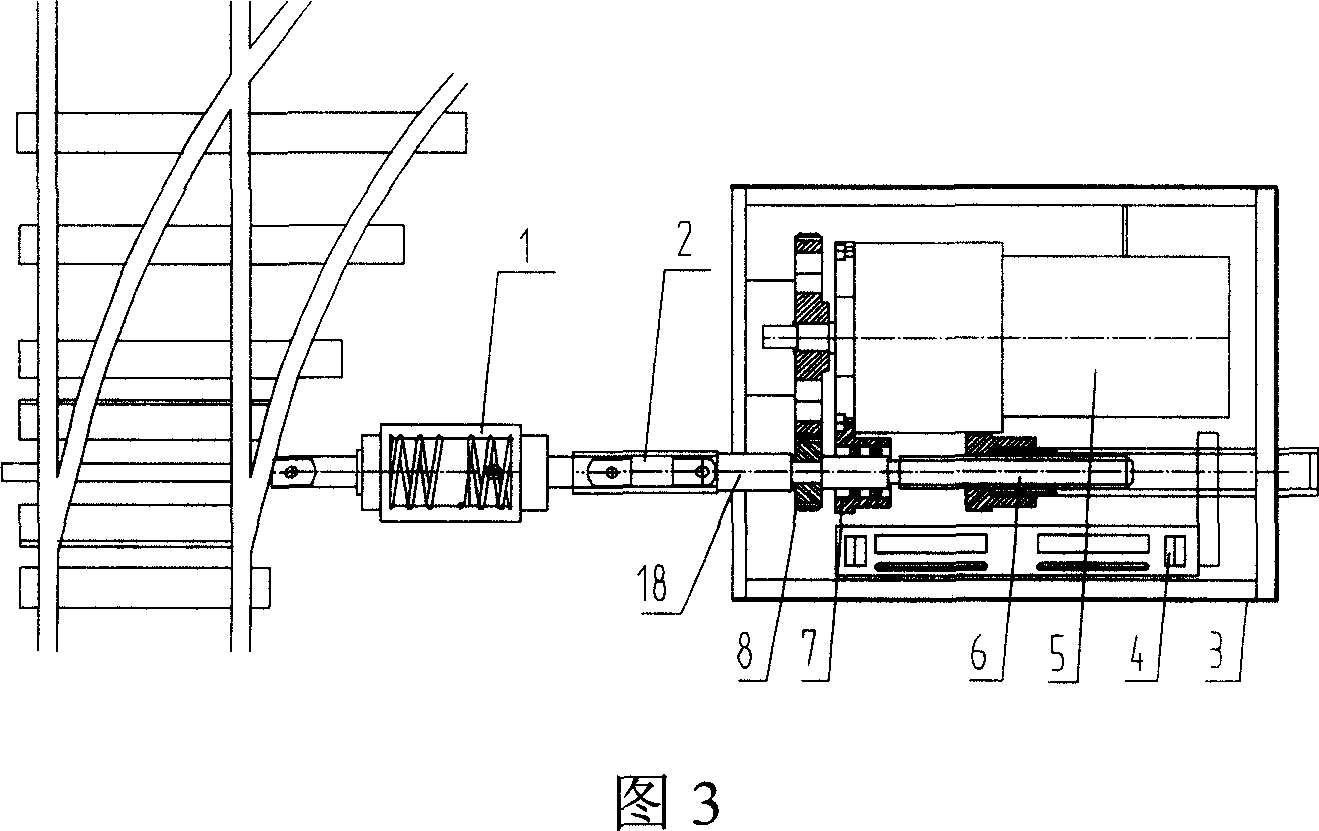

[0029] Embodiment 3: described power machine comprises electric motor 5, travel switch 4, push rod 18, thread pair 6, gear pair 8 and frame 7, and the shaft of thread pair 6 is connected on the frame 7, at one end of thread pair Sequence is connected with push rod 18 and gear pair 8, and the driving wheel of gear pair is connected with motor 5, and travel switch 4 is positioned on the motion locus of screw thread pair, and other is the same with embodiment 1, omits.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com