High-precision and large-load control system and method of three-axis inertially stabilized platform for airborne remote sensing

An aerial remote sensing and three-axis inertial technology, which is applied in the field of light and high-resolution aerial remote sensing inertial stabilization platform, can solve the problems of inability to solve arbitrary manual control, no manual mode, unfavorable real-time and rapidity of control algorithms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

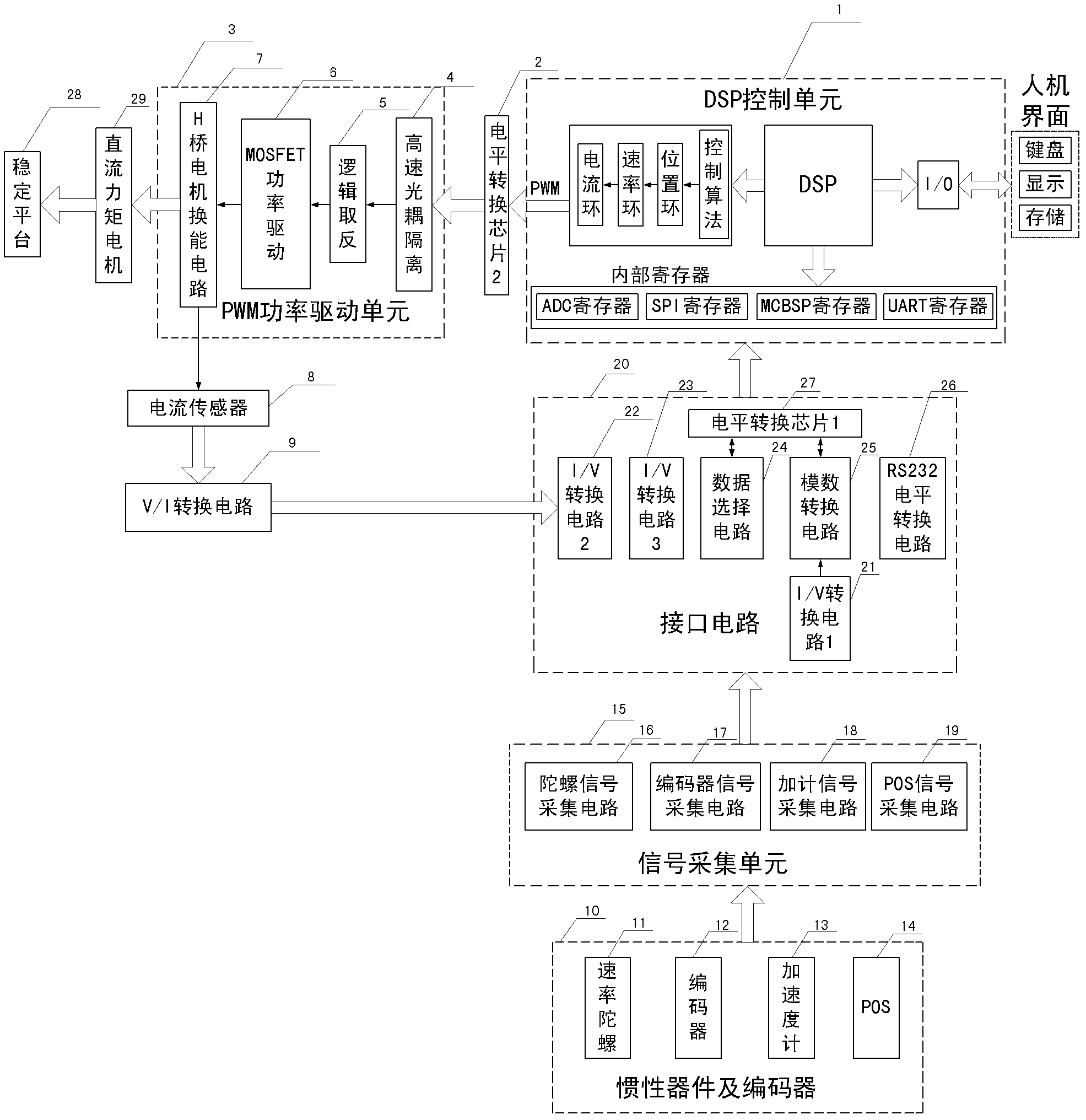

[0046] Such as figure 1 Shown is a structural block diagram of the control system of the present invention, which is mainly composed of a DSP control unit 1, a PWM power drive unit 3, an interface circuit 20, a signal acquisition unit 15, an inertial device, an encoder 10, and the like.

[0047] Among them, the DSP chooses TI's floating-point chip TMS320F28335, which has 32-bit floating-point processing unit, 150MHZ high-speed data processing capability, up to 18 channels of PWM output, 12-bit 16-channel ADC and other characteristics. The register resource is connected with the interface circuit to read the data of each sensor and generate the PWM control value to drive the motor. In the PWM power drive unit 3, the PWM control value is sent to the power drive unit 6 through high-speed optocoupler isolation 4 and logic inversion 5 to increase the output power. Can control.

[0048] Such as figure 1As shown, the current sensor 8 measures the motor coil current, connects to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com