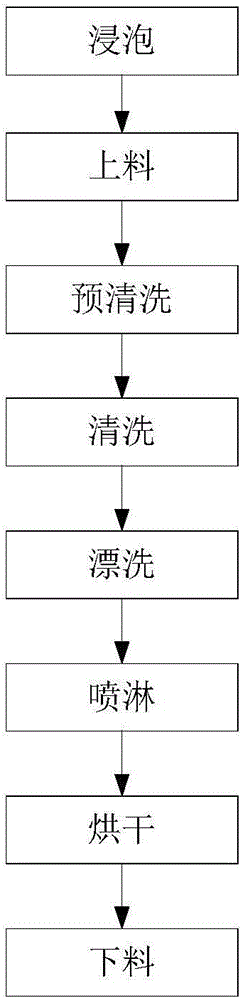

Automatic cleaning method for numbering machine

An automatic cleaning and numbering machine technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc. The effect of reducing the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

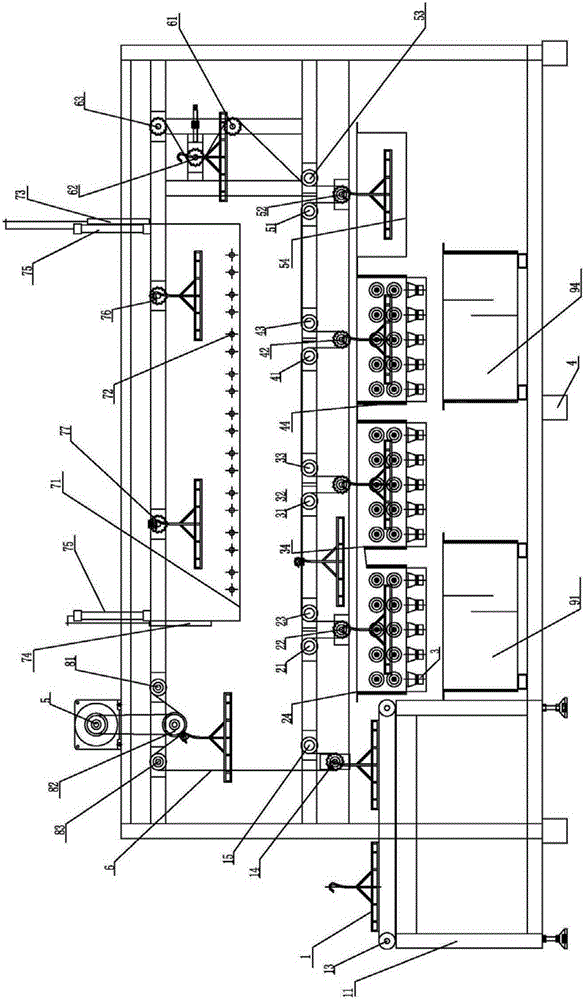

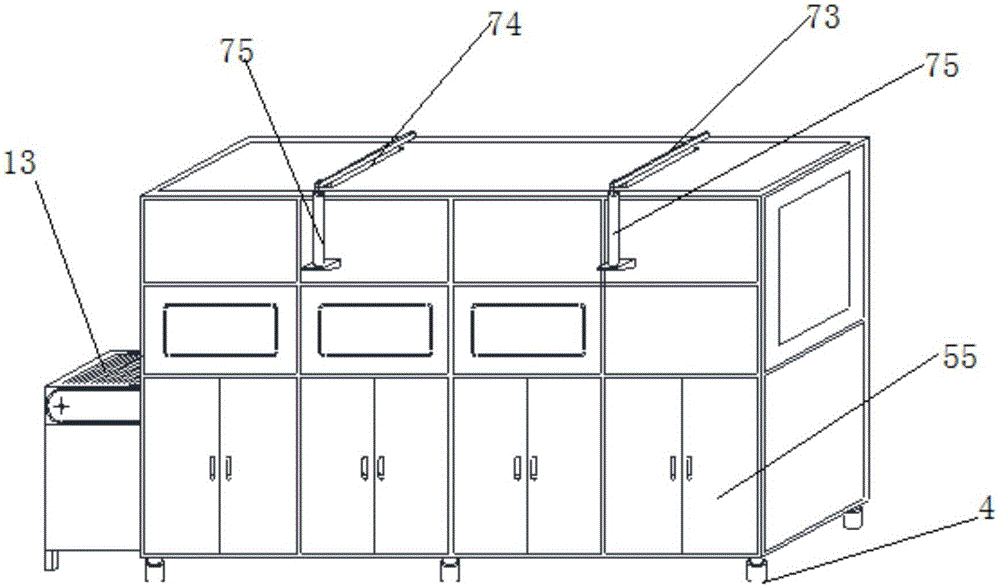

[0040] The automatic cleaning equipment of the present invention is mainly composed of an independent ultrasonic soaking equipment, a main frame, a double-track chain sprocket transmission mechanism, a tensioning device, an ultrasonic generator transducer, a cleaning circulation system, a heating and drying system, a hot air circulation system, and a control cabinet ( Manual control and PLC control system), operating system (electronic touch screen), etc. Loading and unloading are driven by the transmission motor through the chain to move the material baskets suspended on the transmission chain together, and the position of the material baskets is identified by the proximity switch to realize the automatic loading and unloading of the material baskets. Driven by the main drive motor, the double chains are driven by the chain drive, and the transmission rods of the double chains are driven to move forward synchronously in a step-by-step manner. The position of the basket is iden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com