Electro-hydraulic integrated control device applied to valve control

A control device and valve control technology, which is applied in the direction of valve operation/release device, valve device, valve details, etc., can solve the problem of difficult control and adjustment of the pressure oil source, inconvenient control of the executive structure, and loose wiring of the hydraulic control servo valve and other problems, to achieve the effect of simple structure, easy oil pressure and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

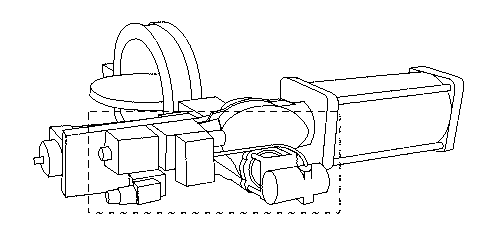

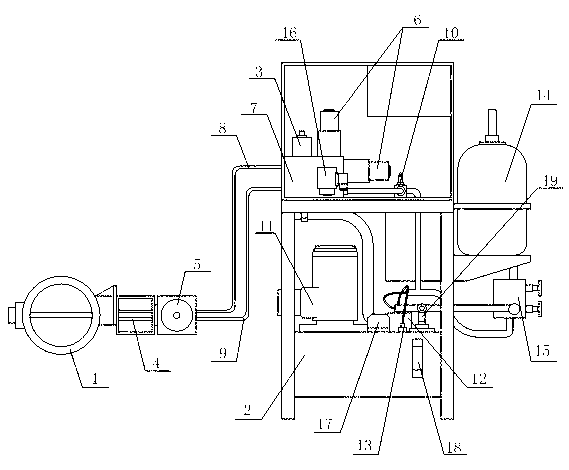

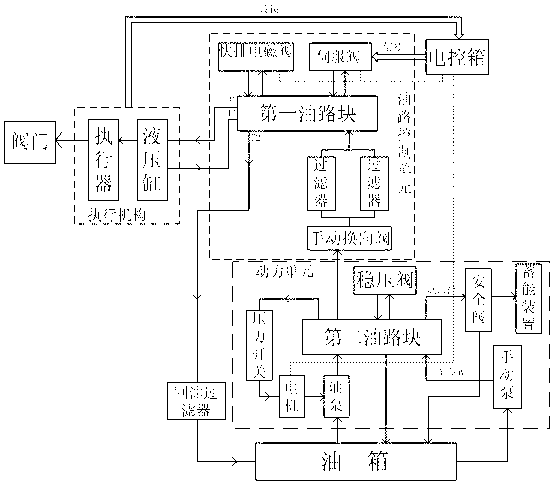

[0030] The present invention proposes an electro-hydraulic integrated control device applied to valve control. Its structure includes an actuator that is connected to the valve 1 and adjusts its valve position. A control component that controls the work of the actuator is connected to the actuator. Generally, In other words, the control components include hydraulically controlled servo valves or proportional valves and various electronic components. In the prior art, the control components are all integrated on the valve actuator, namely figure 1 The structure shown, in figure 1 , the part shown in the dashed box is the control element, and the external oil supply source is usually connected to the control element. In the actual application process, due to the vibration of the control pipeline, high ambient temperature, and large pollution, it often leads to loosening of the control valve (ie: proportional valve or servo valve) and the wiring of various electronic components,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com