Hydraulic motor dragging system used for load of high-power and wide speed adjusting range

A technology of hydraulic motor and drag system, which is applied in the directions of fluid pressure actuation system components, servo motors, fluid pressure actuation devices, etc., can solve the problems of limited technical effect and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

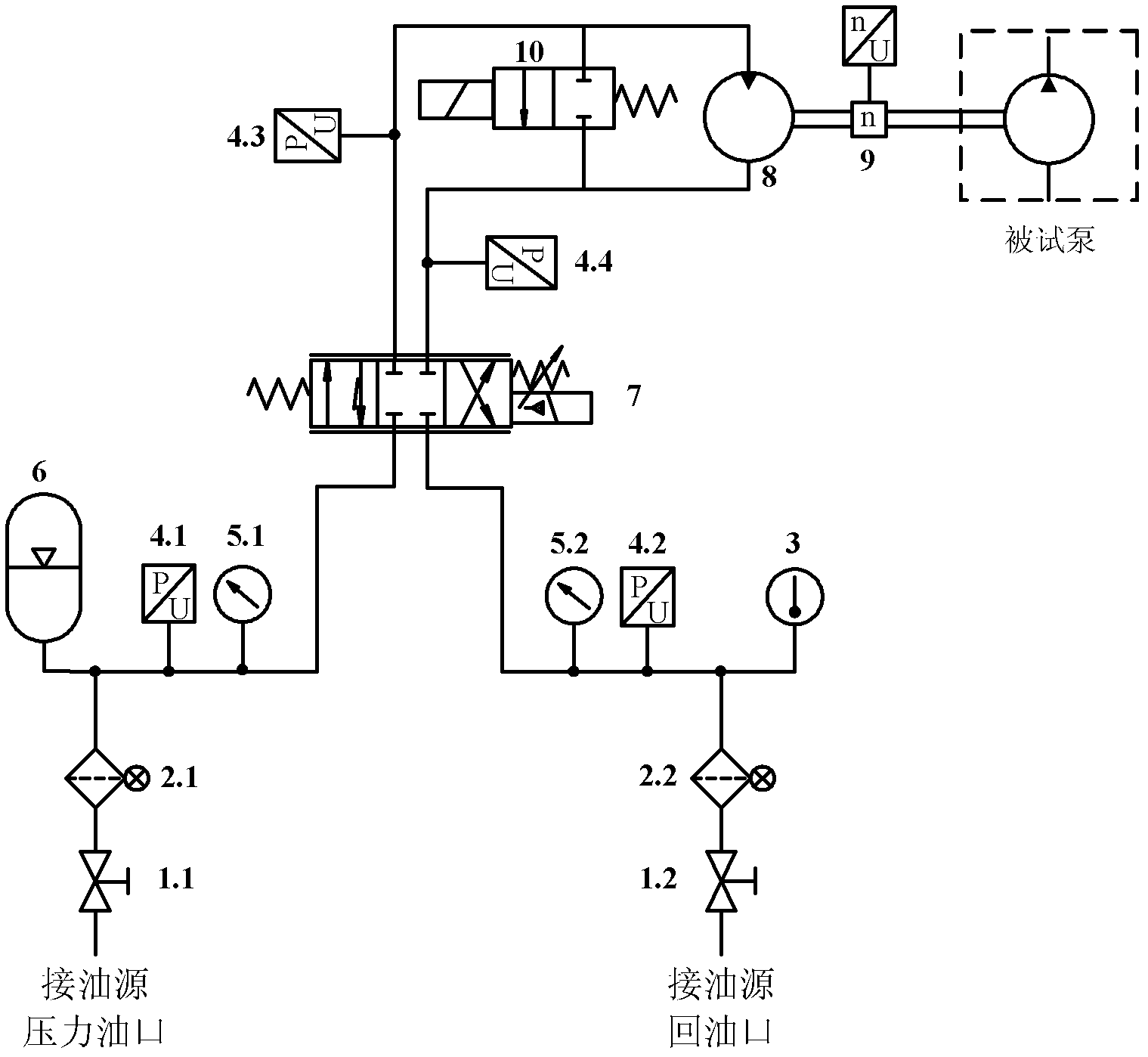

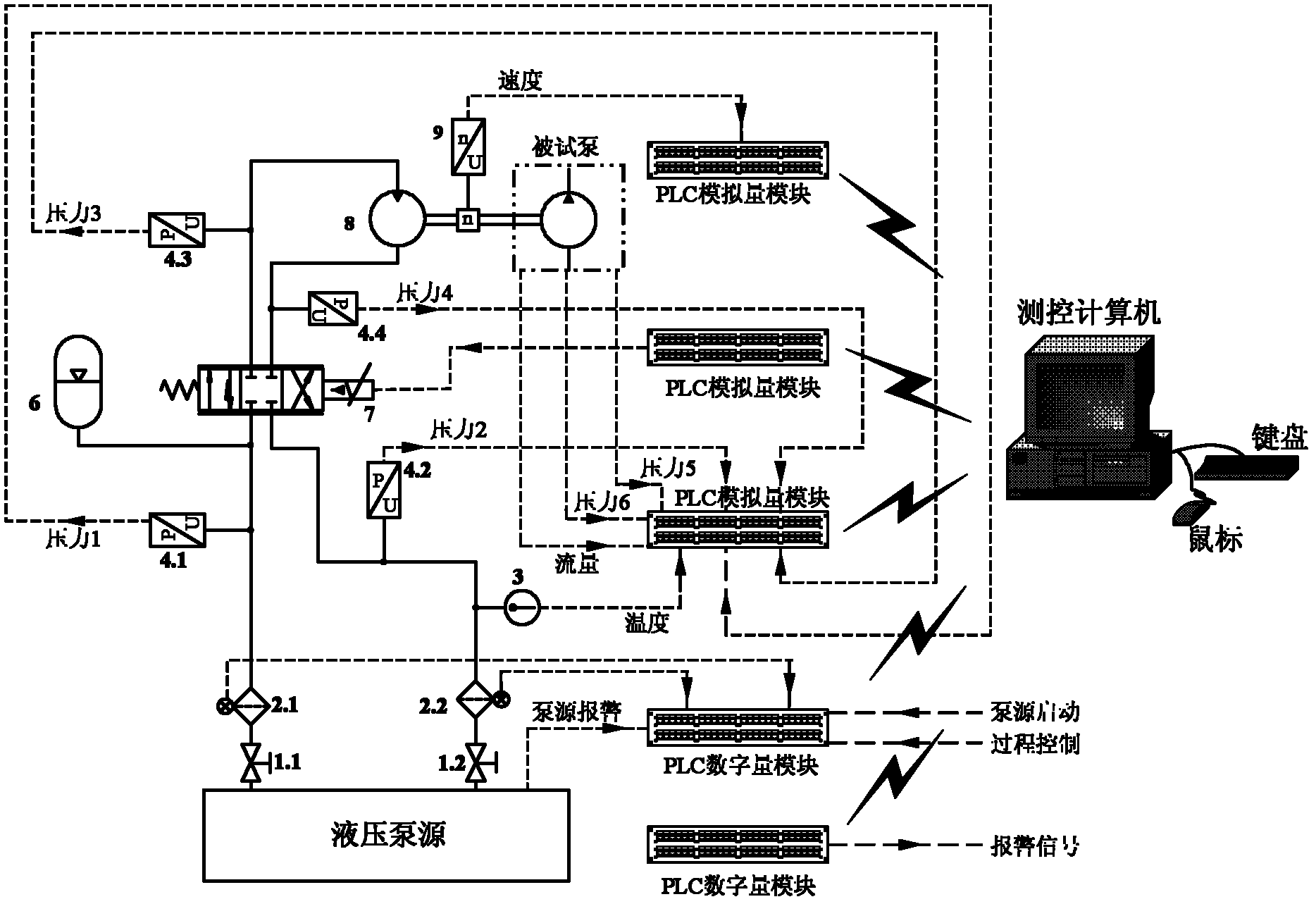

[0105] A hydraulic motor drive system for loads with high power and wide speed regulation range, which is installed on a hydraulic pump; the hydraulic motor drive system is specifically composed of the following two parts: a hydraulic system and an electrical system; wherein: hydraulic The system consists of the following parts: high pressure ball valve 1.1, low pressure ball valve 1.2, high pressure oil filter with alarm 2.1, low pressure oil return filter with alarm 2.2, temperature sensor 3, pressure sensor A4.1, pressure sensor B4.2, Pressure sensor C4.3, pressure sensor D4.4, high pressure gauge 5.1, low pressure gauge 5.2, accumulator 6, servo valve 7, hydraulic motor 8, speed sensor 9, bypass valve 10; where:

[0106] Pressure ball valve 1.1 and low-pressure ball valve 1.2 are respectively connected to the pressure oil port and oil return port of the oil source, high-pressure oil filter 2.1 with alarm is connected to pressure ball valve 1.1, and the following parts are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com