Internal circulating air-cooled pulverizer

An internal circulation type, pulverizer technology, applied in the direction of grain processing, etc., can solve the problems of overheating of the body, affecting the service life of the pulverizer, reducing the pulverization efficiency, etc., to prevent energy loss, improve the utilization rate of cold air, and reduce the maintenance rate of equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

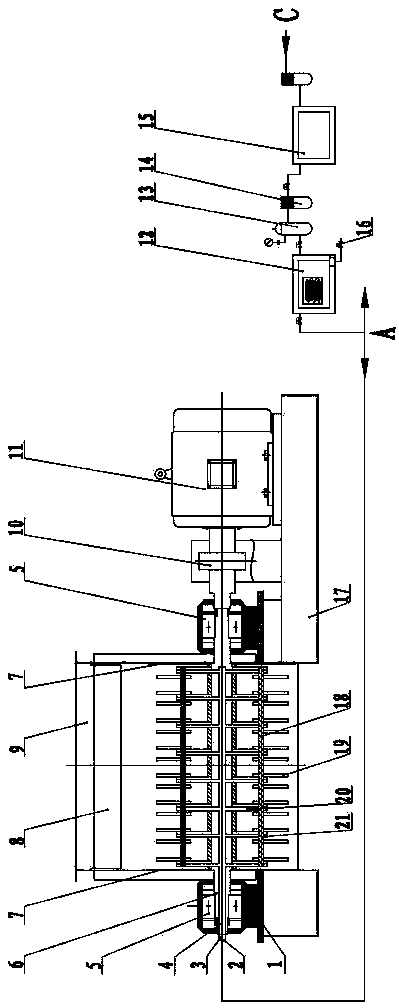

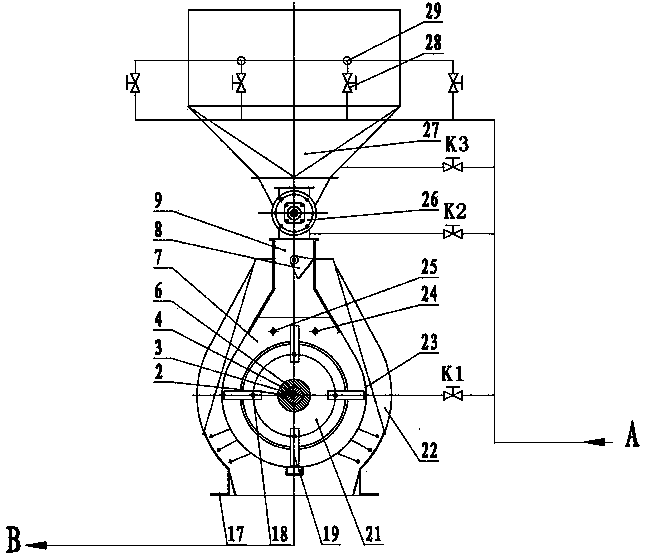

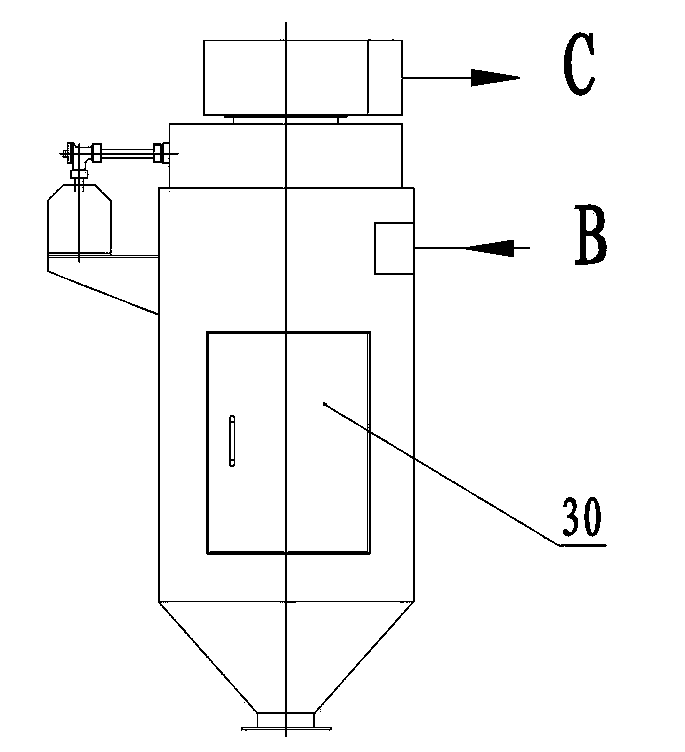

[0040] as shown in the picture figure 1 Structural schematic diagram of the present invention, figure 2 for figure 1 side view diagram of and image 3 It is shown in the air intake and exhaust schematic diagram of the dust separator 30:

[0041] An internal circulation air-cooled pulverizer, including a casing 9, a base 17 and a motor 11, the casing 9 is a pulverization chamber, the pulverization chamber includes a material inlet, a material outlet and a hammer rotor, the hammer rotor Driven by the motor 11 to rotate through the main shaft 6, the hammer rotor is closed by the sieve. The pulverizer also includes a circulating cooling system composed of a freeze dryer 12, an air storage tank 13, a filter tank 14 and an air compressor 15 connected in sequence. Wind system, the main shaft 6 is hollow inside, and the circulating cooling air supply system sends the cooled gas A to the main shaft 6, the crushing chamber and the feeding port respectively through the control valve,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com