Cylindrical grinding machine tailstock

A technology for cylindrical grinding machines and tailstocks, which is applied in the direction of grinding machines, machine tools designed for grinding workpiece rotating surfaces, grinding workpiece supports, etc., and can solve problems such as the axis line between the tip shaft and the workpiece spindle with a large impact force, and achieve The effects of improving stability, improving production efficiency, and improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

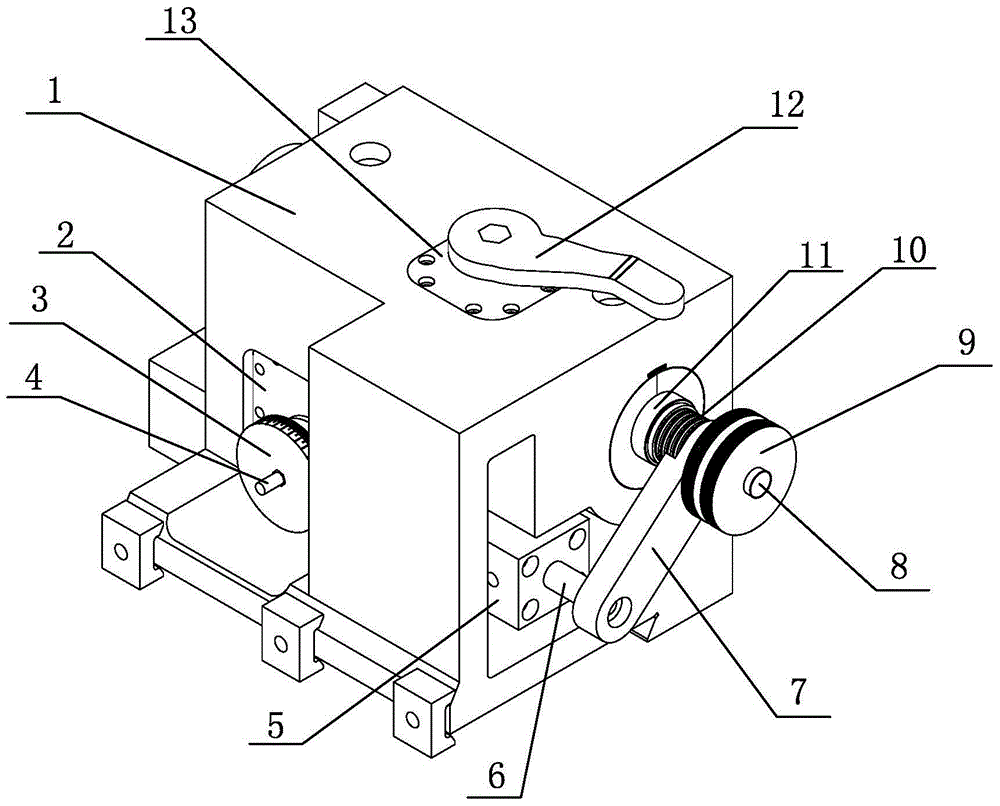

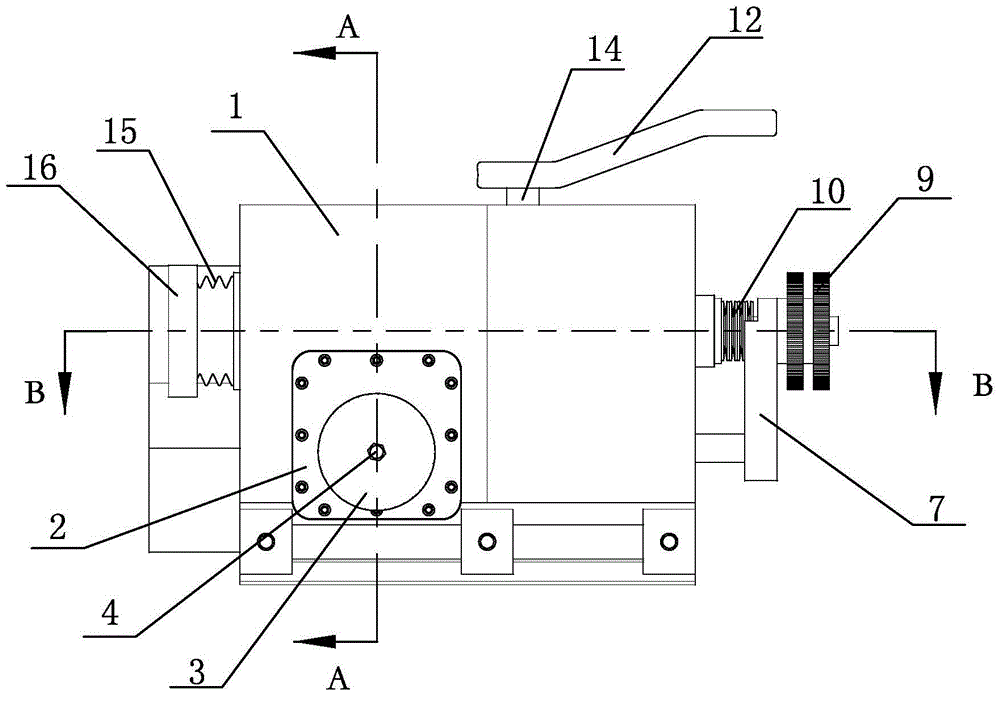

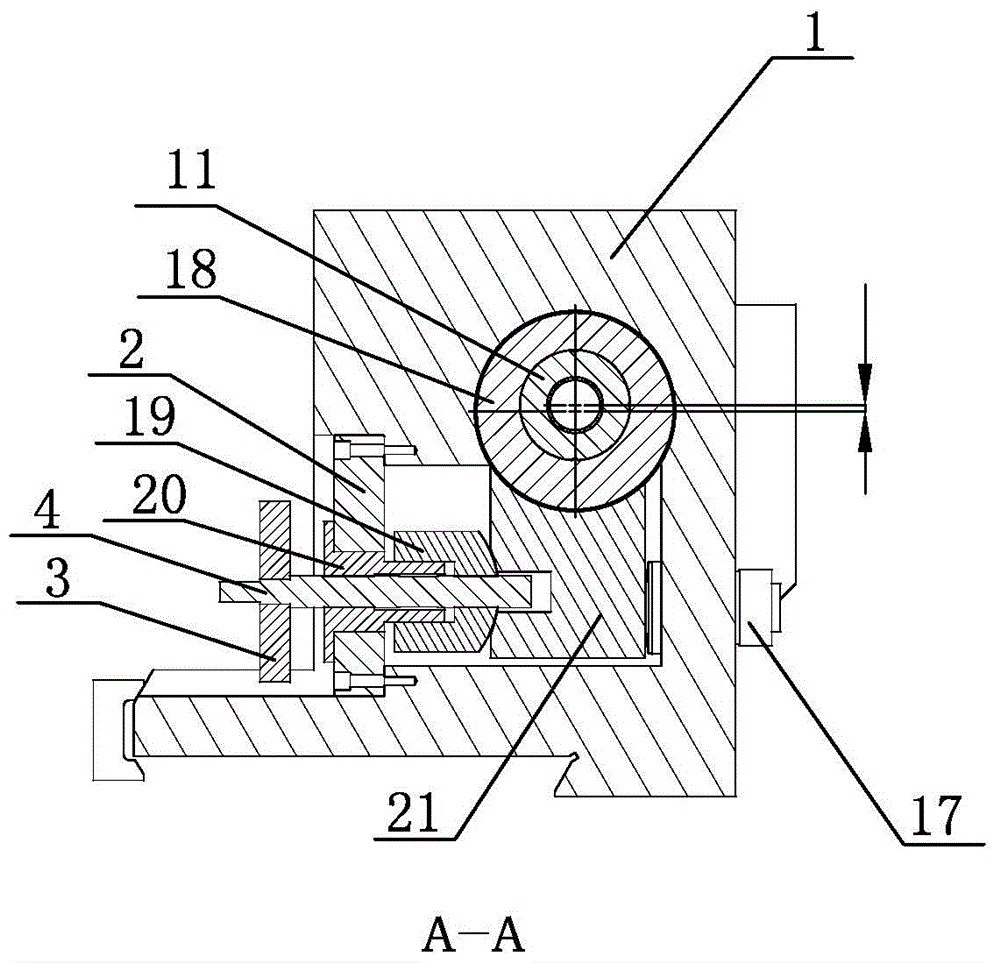

[0012] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0013] Such as Figure 1~Figure 4 As shown, the present invention includes a tailstock body 1, a top shaft, a top shaft sleeve 11, a manual control mechanism, a buffer spring 15, an automatic control mechanism, a middle eccentric sleeve 18 and a concentricity adjustment mechanism. The tailstock body 1 is provided with The through-hole is installed horizontally, the top shaft sleeve 11 is slidably inserted into the horizontal through-hole, the top shaft is inserted in the front end of the axial through hole of the top shaft sleeve 11, and the middle eccentric sleeve 18 is installed at the Between the center shaft sleeve 11 and the transverse installation through hole; the outer circular surface of the center shaft sleeve 11 close to the end of the workpiece is provided with an end shoulder facing the end, and the center shaft sleeve 11 faces the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com