Quantum dot phosphor for light emitting diode and method of preparing the same

a light-emitting diode and quantum dot technology, applied in the field of quantum dot phosphor for light-emitting diodes and a method of preparing the same, can solve the problems of reducing the light-emitting efficiency of quantum dots, unconfirmed properties of polymers for use in diodes, etc., and achieve excellent light-emitting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0054] (1) Preparation of Quantum Dot Phosphor Supported On KBr Substrate

[0055] 5 ml of a solution of 1 wt % CdSe / CdS nanocrystals synthesized in Preparative Example 1 dispersed in toluene were added to 1 g of KBr powders. While toluene was gradually evaporated at room temperature, the nanocrystals and the powders were well mixed and kneaded. After the solution was dried, the powders were loaded into an oven at 80° C. for 6 hr, to completely dry toluene, thereby preparing a quantum dot phosphor supported on a KBr substrate. The dried KBr powders represented the color of CdSe / CdS nanocrystals, and the nanocrystals were present in the efficiently dispersed state on the KBr substrate.

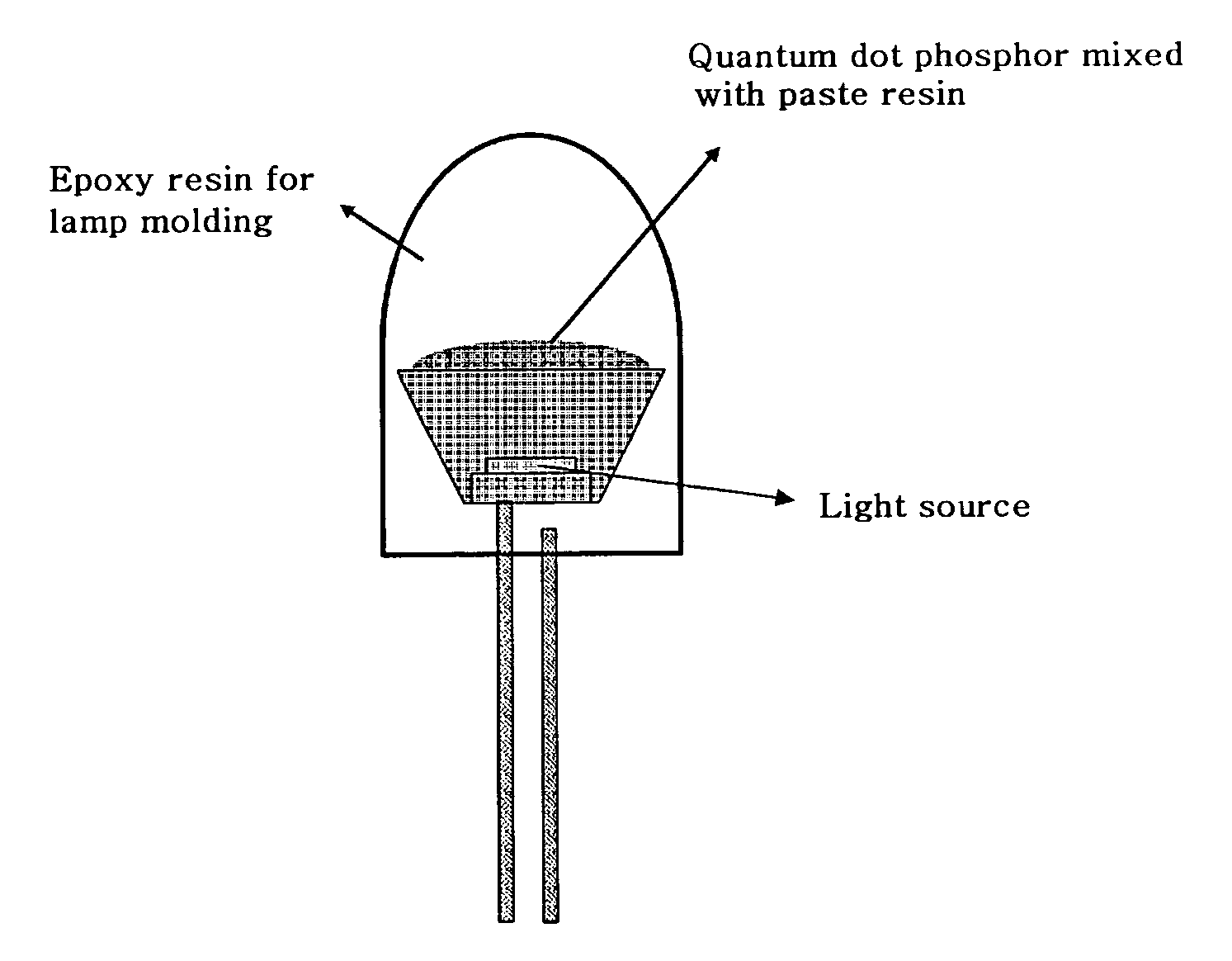

[0056] (2) Fabrication of Light Emitting Diode

[0057] The quantum dot phosphor comprising nanocrystals dispersed and supported on KBr powders was mixed with 2 g of a solution of an epoxy resin and a curing agent mixed at a weight ratio of 1:1, to prepare a mixture of powders and an epoxy resin. The mixtu...

example 2

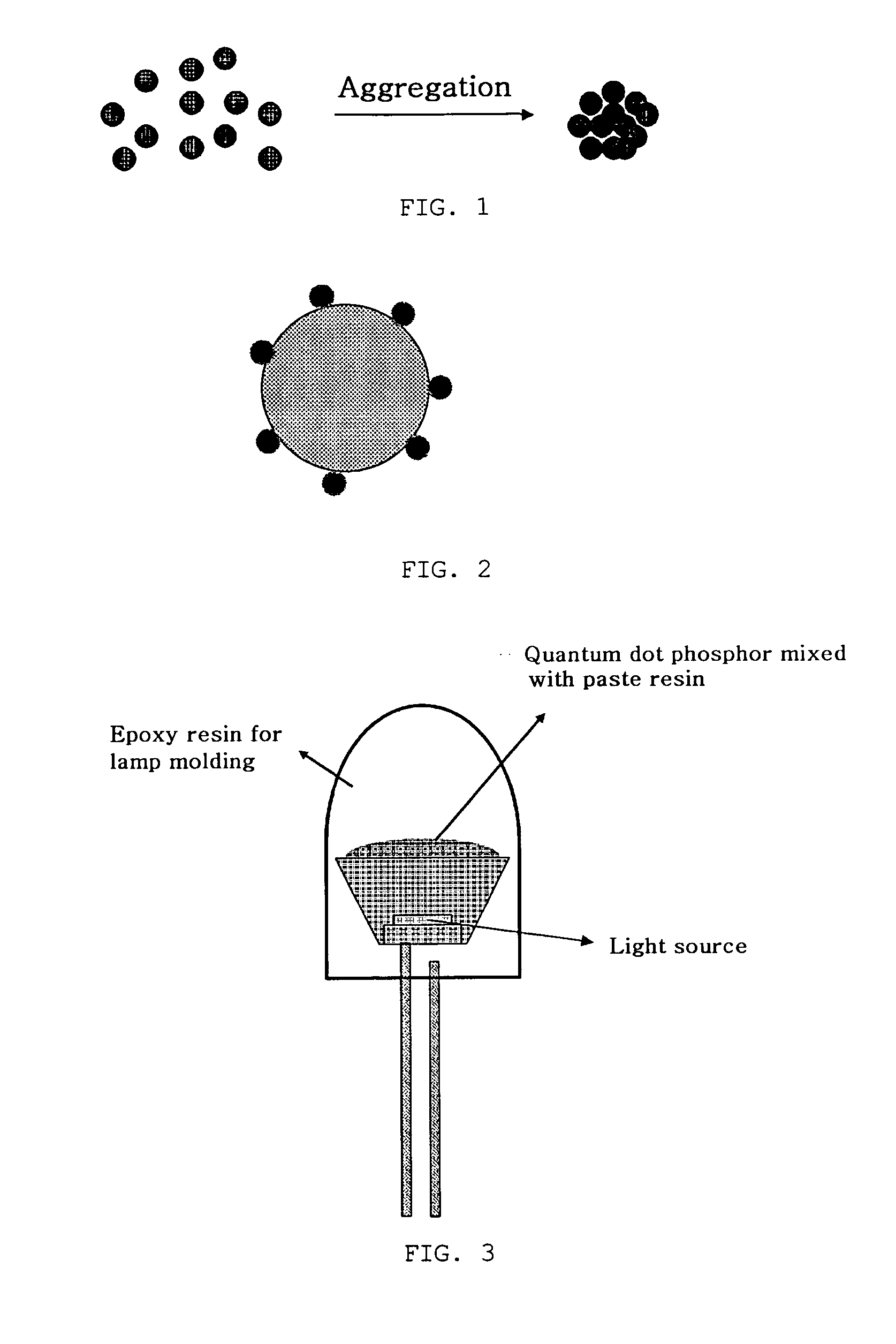

[0058] (1) Preparation of Quantum Dot Phosphor Supported On PS Bead Substrate

[0059] 10 ml of 1 wt % plain(hydrophobic)polystyrene microspheres (PS beads) dispersed in an aqueous solution available from Bangs Laboratory were centrifuged and dried. The dried powders were dispersed again in toluene, added with ethanol, centrifuged, and then re-dried, to prepare PS beads without a surfactant. To the PS beads thus separated, 5 ml of a solution of 1 wt % CdSe / CdS nanocrystals synthesized in Preparative Example 1 dispersed in toluene were added. While toluene was gradually evaporated at room temperature, the nanocrystals and the powders were well mixed and kneaded. After the solution was dried, the powders were loaded into an oven at 80° C. for 6 hr, to completely dry toluene, thereby preparing a quantum dot phosphor supported on a PS bead substrate. The dried PS beads represented the color of CdSe / CdS nanocrystals, and the nanocrystals were present in the efficiently dispersed state on t...

example 3

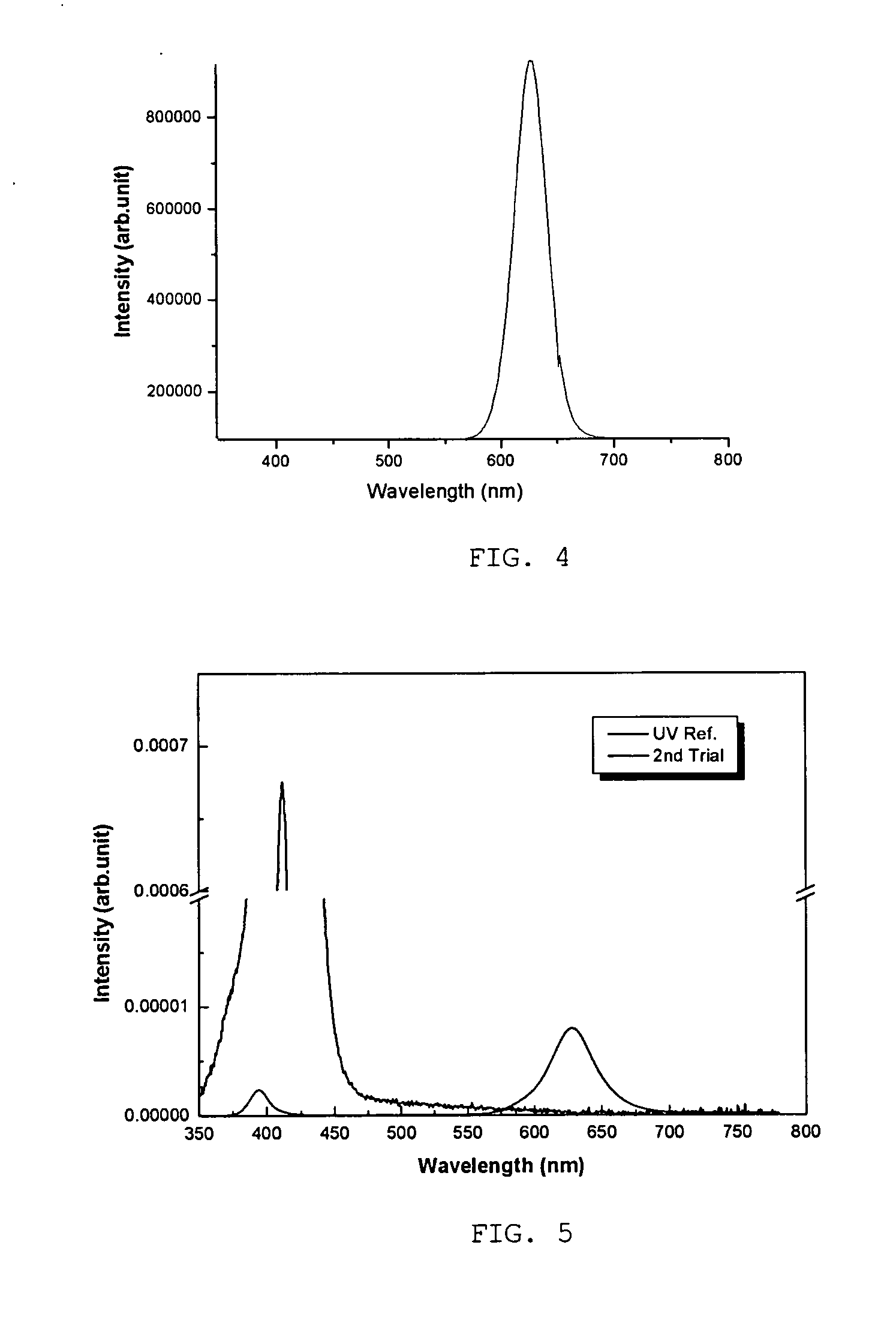

[0062] (1) Preparation of Quantum Dot Phosphor Supported on Inorganic Phosphor

[0063] 5 ml of a solution of 1 wt % CdSe / CdS nanocrystals synthesized in Preparative Example 1 dispersed in toluene were added to 1 g of LDP-R3 inorganic phosphor((Zn,Cd)S:Ag+In2O3, available from Kasei Optonix). While toluene was gradually evaporated at room temperature, the nanocrystals and the phosphor were well mixed and kneaded. After the solution was dried, the phosphor was loaded into an oven at 80° C. for 6 hr, to completely dry toluene, thereby preparing a sample 1. Separately, another phosphor having nanocrystals dispersed and supported thereon was prepared in the same manner as in the preparation of the sample 1, and then, dispensing and drying of nanocrystals were further performed once, to prepare a sample 2.

[0064] (2) Fabrication of Light Emitting Diode

[0065] LDP-R3 inorganic phosphor, and the samples 1 and 2 were each mixed with 2 g of a solution of an epoxy resin and a curing agent mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com