C/SiC composite surface coating system and preparation method thereof

A composite material and surface coating technology, which is applied in the field of high temperature resistant fiber reinforced ceramic matrix composite materials, can solve the problems of limited temperature resistance of glass phase, damage to the composite material substrate, unsatisfactory performance, etc., so as to improve oxidation resistance and erosion resistance. ability, avoid cracking or peeling, avoid adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

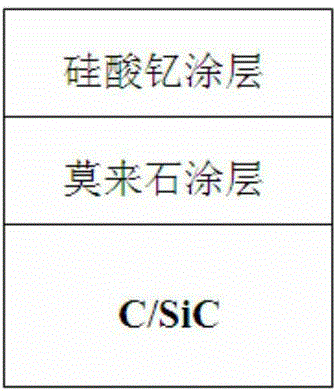

[0044] A kind of C / SiC composite surface coating system of the present invention, such as figure 1 As shown, the surface coating system is set on the surface of the C / SiC composite substrate, and the surface coating system includes mullite (3Al 2 o 3 2SiO2 2 ) coating and yttrium silicate coating.

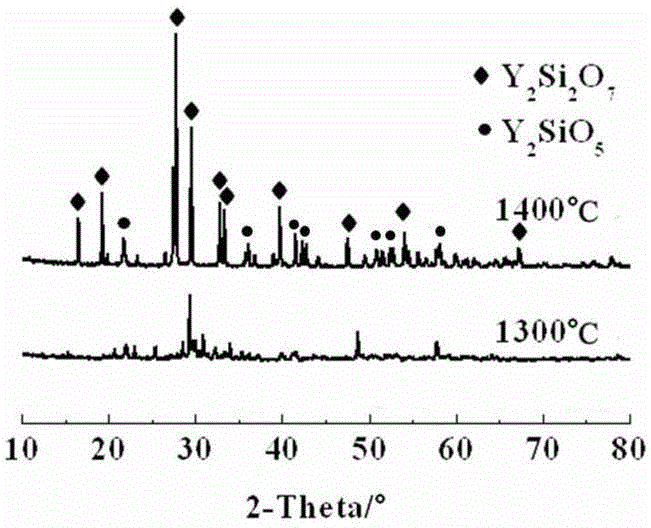

[0045] In this embodiment, the yttrium silicate coating is Y 2 Si 2 o 7 Single-phase coating with a single layer thickness of 30 μm. The thickness of the mullite coating is 15 μm.

[0046] A preparation method of the C / SiC composite material surface coating system of the above-mentioned present embodiment, comprising the following steps:

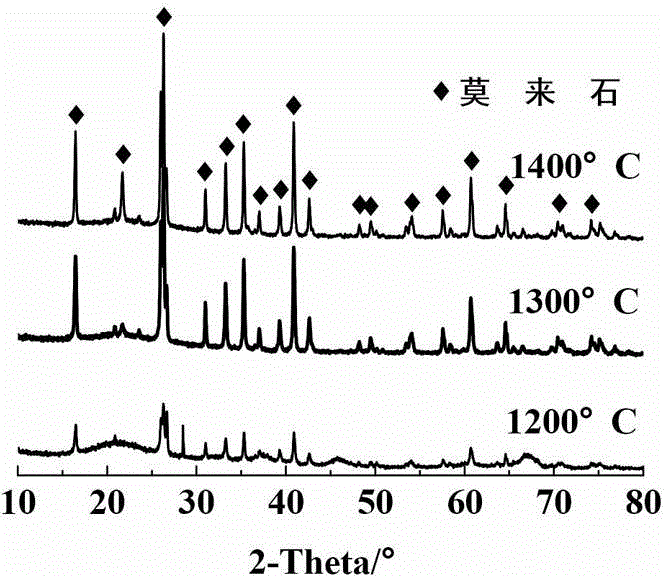

[0047] (1) Al 2 o 3 Sol and SiO 2 Sol (both commercially available) mixed, Al 2 o 3 and SiO 2 The mass ratio of Al is 1:1, and the Al 2 o 3 -SiO 2 Composite sol, as raw material for mullite coating.

[0048] (2) Raw materials for preparing yttrium silicate coating slurry: Silicone resin and Y 2 o 3 Powder (average particle size...

Embodiment 2

[0053] A kind of C / SiC composite surface coating system of the present invention, such as figure 1 As shown, the surface coating system is provided on the surface of the C / SiC composite substrate, and the surface coating system includes a mullite coating and an yttrium silicate coating arranged sequentially from bottom to top.

[0054] In the present embodiment, yttrium silicate coating is 30wt%Y 2 SiO 5 and 70wt%Y 2 Si 2 o 7 The hybrid coating has a single layer thickness of 75 μm. The thickness of the mullite coating is 25 μm.

[0055] A preparation method of the C / SiC composite material surface coating system of the above-mentioned present embodiment, comprising the following steps:

[0056] (1) Al 2 o 3 Sol and SiO 2 Sol mixing, Al 2 o 3 and SiO 2 The mass ratio of Al is 2:1, and the Al 2 o 3 -SiO 2 Composite sol, as raw material for mullite coating.

[0057] (2) Raw materials for preparing yttrium silicate coating slurry: Silicone resin and Y 2 o 3 Powde...

Embodiment 3

[0062] A kind of C / SiC composite surface coating system of the present invention, such as figure 1 As shown, the surface coating system is provided on the surface of the C / SiC composite substrate, and the surface coating system includes a mullite coating and an yttrium silicate coating arranged sequentially from bottom to top.

[0063] In this embodiment, the yttrium silicate coating is 30wt% Y from bottom to top (also from inside to outside) 2 SiO 5 and 70wt%Y 2 Si 2 o 7 mixed coating, 70wt%Y 2 SiO 5 and 30wt%Y 2 Si 2 o 7 Hybrid coating, Y 2 SiO 5 Single-phase coating, the thickness of each single layer is 35 μm, and the total thickness of the yttrium silicate coating is 105 μm. The thickness of the mullite coating is 21 μm.

[0064] A preparation method of the C / SiC composite material surface coating system of the above-mentioned present embodiment, comprising the following steps:

[0065] (1) Al 2 o 3 Sol and SiO 2 Sol mixing, Al 2 o 3 and SiO 2 The mass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com