Production process for hot-rolled composite blank

A production process and hot-rolled cladding technology, which is used in manufacturing tools, metal rolling, and metal processing equipment, etc., can solve the problems of large climate impact of explosive cladding, not meeting environmental-friendly requirements, and difficult to guarantee mass production. The effect of ensuring vacuum degree, improving weldability and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

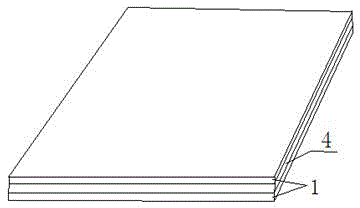

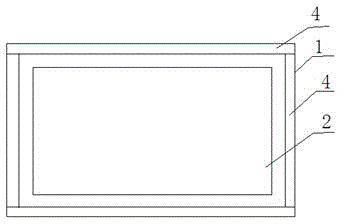

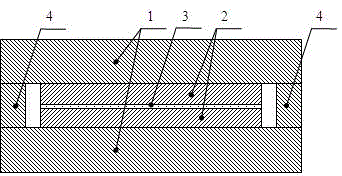

[0025] Example 1 A production process of a hot-rolled composite billet, the hot-rolled composite billet includes two base metal plates 1, two clad metal plates 2, a high-temperature anti-adhesive agent 3 and a substrate metal strip 4, and the clad metal plate The side lengths of 2 are all smaller than the side lengths of base metal plate 1, and the production process includes the following steps:

[0026] (1) Clean the base metal plate and the clad metal plate, and use a milling machine to clean the surface of the composite surface to make the surface clean;

[0027] (2) Stack two clad metal plates 2, place light magnesium oxide superfine powder (high temperature anti-sticking agent 3) between the clad metal plates, and place the stacked clad metal plates on the two base metal plates In the middle of the plate 1, and the distance from the corresponding two sides of the clad metal plate 2 to the corresponding two sides of the base metal plate 1 is equal;

[0028] (3) Place the...

Embodiment 2

[0034] Example 2 A production process of a hot-rolled composite blank, 30mm (5mm+25mm) thick 304 / Q345B stainless steel / carbon steel composite plate, the size of the composite plate blank: 240×1620×2500 (mm), including two base metals Plate 1, two clad metal plates 2, high temperature anti-adhesive agent 3 and substrate metal strip 4; the base metal plate 1 is a 100mm thick Q235B steel plate with a size of 100×1620×2500mm (mm); the clad metal The plate 2 is a 20mm thick 304 stainless steel plate with a size of 20×1500×2380mm (mm); the high-temperature anti-sticking agent 3 is alumina superfine powder; the substrate metal strip 4 includes two pieces of 40×50×2500 (mm) Q235B steel strips and two 40×50×1520 (mm) Q235B steel strips.

[0035] The production process includes the following steps:

[0036] (1) Clean the base metal plate 1 and the clad metal plate 2 to make the surface clean; use a milling machine to clean the surfaces of the two base metal plates 1 and the clad metal ...

Embodiment 3

[0042] Example 3 A hot-rolled composite billet, a production process of 13 (1+12) mm thick TA2 / Q235B titanium-steel composite plate, the composite plate includes two base metal plates 1, two clad metal plates 2, High-temperature anti-adhesive agent 3 and substrate metal strip 4, the base metal plate is a 120mm thick Q235B steel plate with a size of 120×1620×2300 (mm), and the multilayer metal plate is a 10mm thick TA2 titanium plate with a size of: 10×1500×2180 (mm), the high-temperature anti-adhesive agent 3 is light magnesium oxide ultrafine powder, the substrate metal strip 4 is Q235B steel strip, and the size is 20×50×2300 (mm). The size is 20×50×1520 (mm) two pieces;

[0043] The production process includes the following steps:

[0044](1) Clean the base metal plate 1 and the clad metal plate 2 to make the surface clean; use a milling machine to clean the surfaces of the base metal plate 1 and the clad metal plate 2;

[0045] (2) Stack two clad metal plates 2, place lig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Interfacial shear strength | aaaaa | aaaaa |

| Interfacial shear strength | aaaaa | aaaaa |

| Interfacial shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com