Room temperature catalyst for removing formaldehyde in air and method of preparing the same

An oxidation catalyst, formaldehyde technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as expensive catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Preparation of Co-Ce-Sn composite oxide cordierite honeycomb ceramic support: Dissolve cobalt nitrate, cerium nitrate and tin chloride in di-(2-ethylhexyl) sodium sulfosuccinate (AOT) / In ethanol / deionized aqueous solution (where the molar ratio of AOT, ethanol, and water is 5:30:80), according to the appropriate Co-Ce-Sn molar ratio (see Table 1), the above three solutions were mixed and stirred vigorously Add appropriate amount of H under the condition 2 o 2 , H 2 o 2 The molar ratio to the metal ions in the solution is 1:1; an appropriate amount of ammonia water with a concentration of 0.20 mol / l is added dropwise to the mixed solution, and its pH value is finally adjusted to 7-9; the resulting colloidal liquid mixture is ultrasonically treated for 1 hour ; The precipitate in the colloidal liquid mixture was centrifuged, washed with deionized water, and dried at 110°C for 24h to obtain a composite oxide precursor, which was then roasted in air at 400°C for 2h to o...

Embodiment 2

[0024] Preparation of catalysts A-E: The coated Co-Ce-Sn composite oxide cordierite honeycomb ceramic carrier obtained in Example 1 was impregnated in Pt(NH 3 ) 2 (NO 2 ) 2 In aqueous solution, the concentration of Pt is 0.01mol / l. Take it out and dry it in the air at 110°C for 2 hours to obtain a loaded Pt precursor, and then treat the loaded Pt precursor at 200°C in pure hydrogen for 2 hours. The content of Pt accounts for 1.0% of the composite oxide.

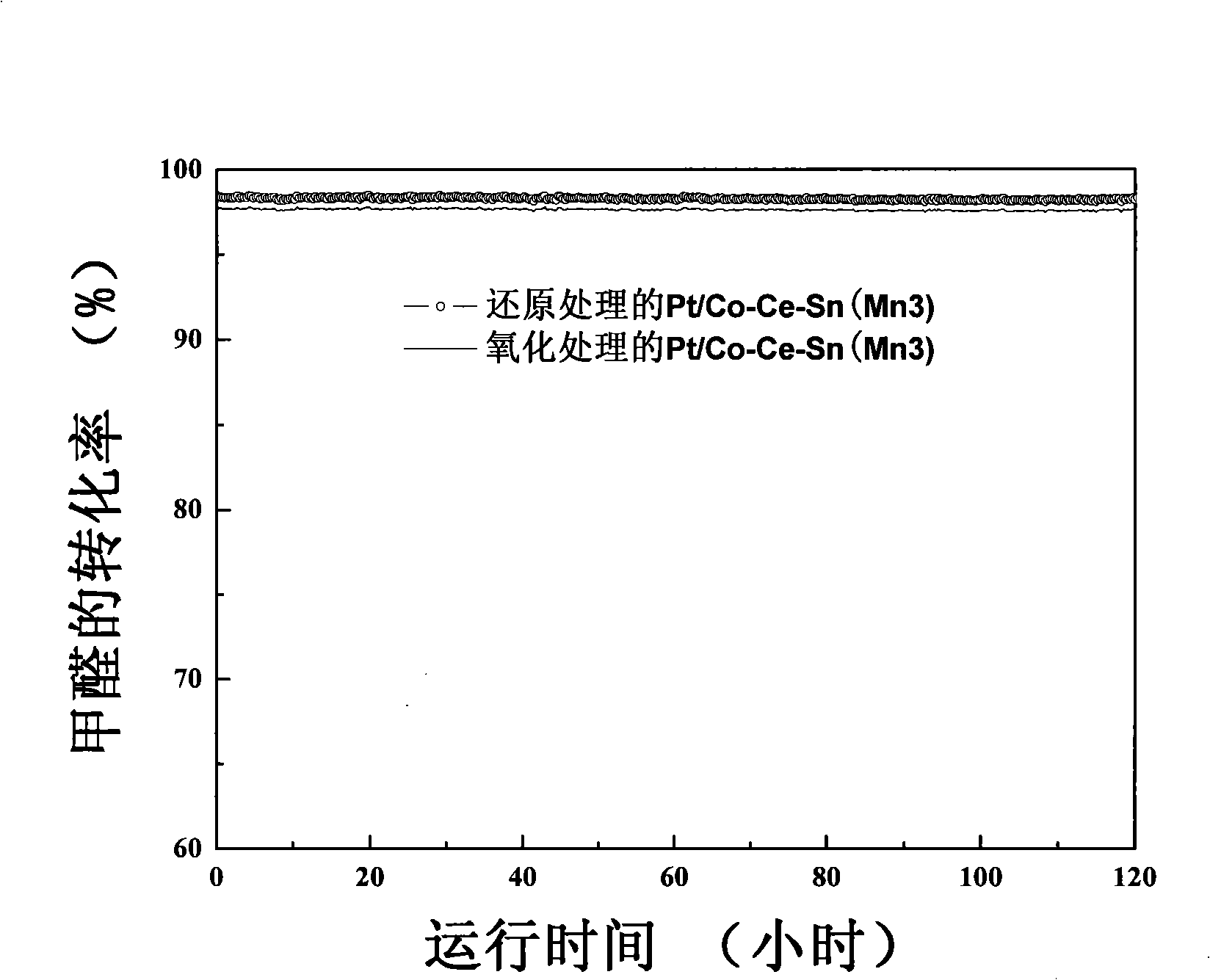

[0025] Catalyst performance tests were carried out in a continuous-flow fixed-bed reactor. Cylindrical cordierite honeycomb ceramic catalyst (high 23mm, diameter 20mm, 400 holes / inch) loaded in a glass tube, at room temperature (18-25 ℃) and relative humidity of 70%, pass through the 3 For formaldehyde air, the wind speed is 2.5m / s. Reactor outlet gas was analyzed by Innoval312 gas concentration detector and trace gas analysis mass spectrometer (PTR-MS) at the same time. Experiments show that formaldehyde is completely...

Embodiment 3

[0027] Preparation of Catalysts F-K with different Pt contents: The Co-Ce-Sn composite oxide cordierite honeycomb ceramic carrier obtained in Example 1 was impregnated in Pt(NH 3 ) 2 (NO 2 ) 2 In the aqueous solution, the concentration of Pt in the solution is adjusted so that the content of Pt in the finished catalyst accounts for 0-10% of the composite oxide. Take it out and dry it in the air at 110° C. for 2 hours to obtain a loaded Pt precursor, and then treat the loaded Pt precursor at 200° C. in pure hydrogen for 2 hours.

[0028] The performance test of the catalyst is the same as in Example 2. The experiment shows that formaldehyde is completely decomposed into harmless water and carbon dioxide, without by-products such as formic acid, carbon monoxide and methyl formate. The results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com