Sealing adhesive strip for ribbed self-adhesive glass and manufacturing method thereof

A glass sealing and sealant technology, applied in chemical instruments and methods, adhesives, other chemical processes, etc., can solve the problems of silicone structural adhesives such as poor water and air tightness, poor followability, and complicated construction technology, and achieve excellent air tightness. The effects of tightness and watertightness, good elasticity and followability, and simple construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

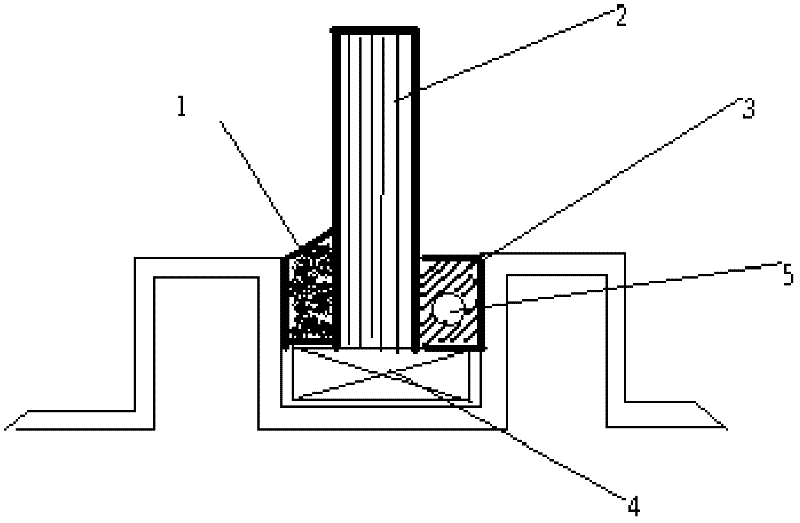

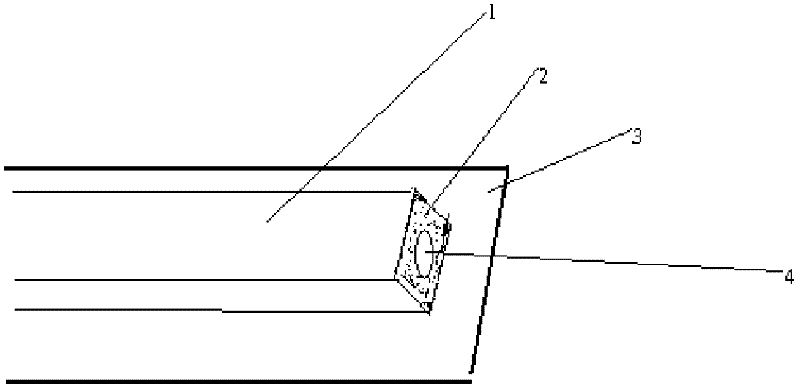

Image

Examples

Embodiment 1

[0063] Manufacture the self-adhesive glass sealing strip with ribs of the present invention according to the following steps

[0064] ① Butyl rubber sealant compound mixing and kneading

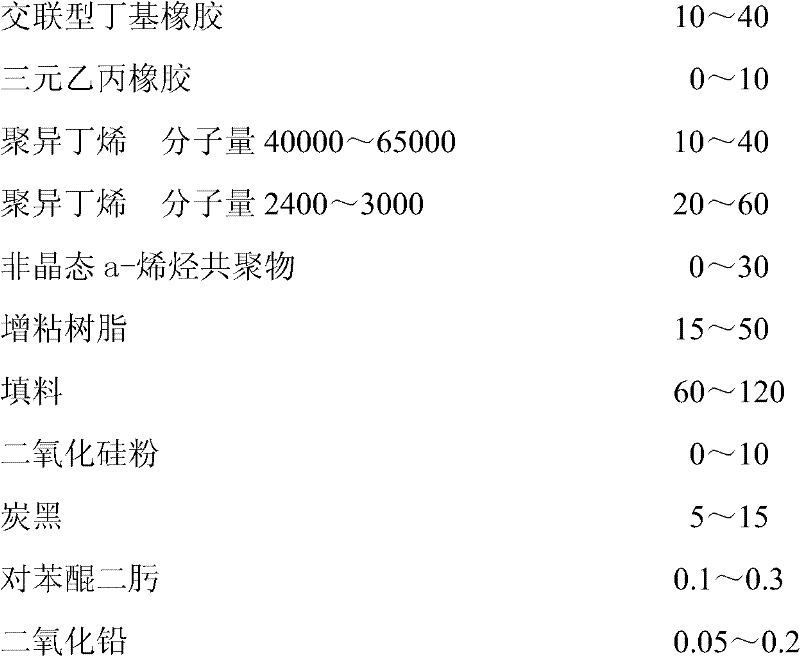

[0065] Add 30 parts by weight of cross-linked butyl rubber Yanshan Petrochemical 1751), 5 parts by weight of EPDM rubber (DSM5508 in the Netherlands), 20 parts by weight of polyisobutylene with a molecular weight of 40000 and 40 parts by weight of polyisobutylene with a molecular weight of 2400, and add them to the internal mixer Heat up to 160°C, knead for one hour, then add α-olefin copolymer APAO Germany Degussa 79220 parts by weight, cool down to 140°C, knead for one hour, add tackifying resin (terpene resin, softening point (100°C) 30 parts by weight, after continuing to knead for 30 minutes, add 100 parts by weight of filler calcium carbonate powder (1250 mesh), 5 parts by weight of silicon dioxide (gas phase method), 10 parts by weight of carbon black (pigment grade), Cool down to 120...

Embodiment 2~ Embodiment 7

[0071] According to the method and steps of Example 1, according to the formula of Table 1, the self-adhesive glass sealing strip with ribs of the present invention is manufactured

[0072] Table 1

[0073]

[0074]

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com