Carbon nanotube modified titanium based fluorine-containing lead dioxide electrode and preparation method thereof

A carbon nanotube and lead dioxide technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of insufficient current efficiency, poor stability, and easy peeling of the deposited layer, so as to improve the electric current. Catalytic activity, the effect of improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

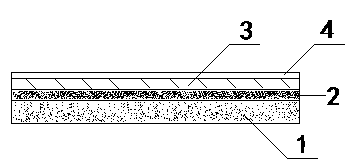

[0034] as attached figure 1 Shown: the structure of the titanium-based fluorine-containing lead dioxide electrode modified by carbon nanotubes of the present invention comprises:

[0035] Titanium plate substrate 1;

[0036] Tin antimony oxide bottom layer 2 thermally deposited on the titanium plate substrate;

[0037] Electrodeposition of α-PbO on Tin Antimony Oxide Underlayer 2 2 middle layer 3;

[0038] Electrodeposition on α-PbO under the action of surfactant 2 Carbon nanotube-modified fluorine-containing β-PbO on the intermediate layer 3 2 Surface active layer 4.

[0039] The preparation method is as follows: First, the titanium plate substrate (30 mm × 50 mm × 0.8 mm) was polished with 120-mesh coarse sandpaper, and then polished with 600-mesh and 1200-mesh fine sandpaper in turn until the titanium plate substrate showed a silvery-white metallic luster. Rinse; ultrasonically treat the polished titanium substrate in acetone for 10 minutes to remove oil stains; then ...

Embodiment 2

[0042] The preparation method of the electrode is the same as in Example 1.

[0043] The difference is that the fluorine-containing β-PbO modified by electrodeposited carbon nanotubes is used 2 The electroplating solution of the surface active layer is 100 milliliters mixed with 5 g / L carbon nanotubes, 0.1 g / L cetyltrimethylammonium bromide, 0.5 mol / L lead nitrate, 0.05 mol / L sodium fluoride and 1 The mixed solution of mol / liter nitric acid obtains the fluorine-containing lead dioxide electrode modified by carbon nanotubes prepared under the action of cetyltrimethylammonium bromide, as shown in Figure 4.

[0044] This electrode is used as the anode, the stainless steel plate of equal area is used as the cathode, and the distance between the poles is 1 cm. The concentration of p-chlorophenol in electrocatalytic oxidation water is 50 mg / L, and 0.05 mol / L of sodium sulfate is used as the supporting electrolyte. The volume of the solution is 200ml and the current density is 30mA / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com