Lead-acid accumulator anode lead plaster

A lead-acid battery, positive lead paste technology, applied in lead-acid battery electrodes, battery electrodes, circuits, etc., can solve the difficulty of taking into account the initial capacity and cycle life of the battery, affecting the battery's ability to accept charging, and increasing the internal resistance of the battery, etc. problems, to achieve the effect of improving the charging acceptance, improving the efficiency of the formation current, and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

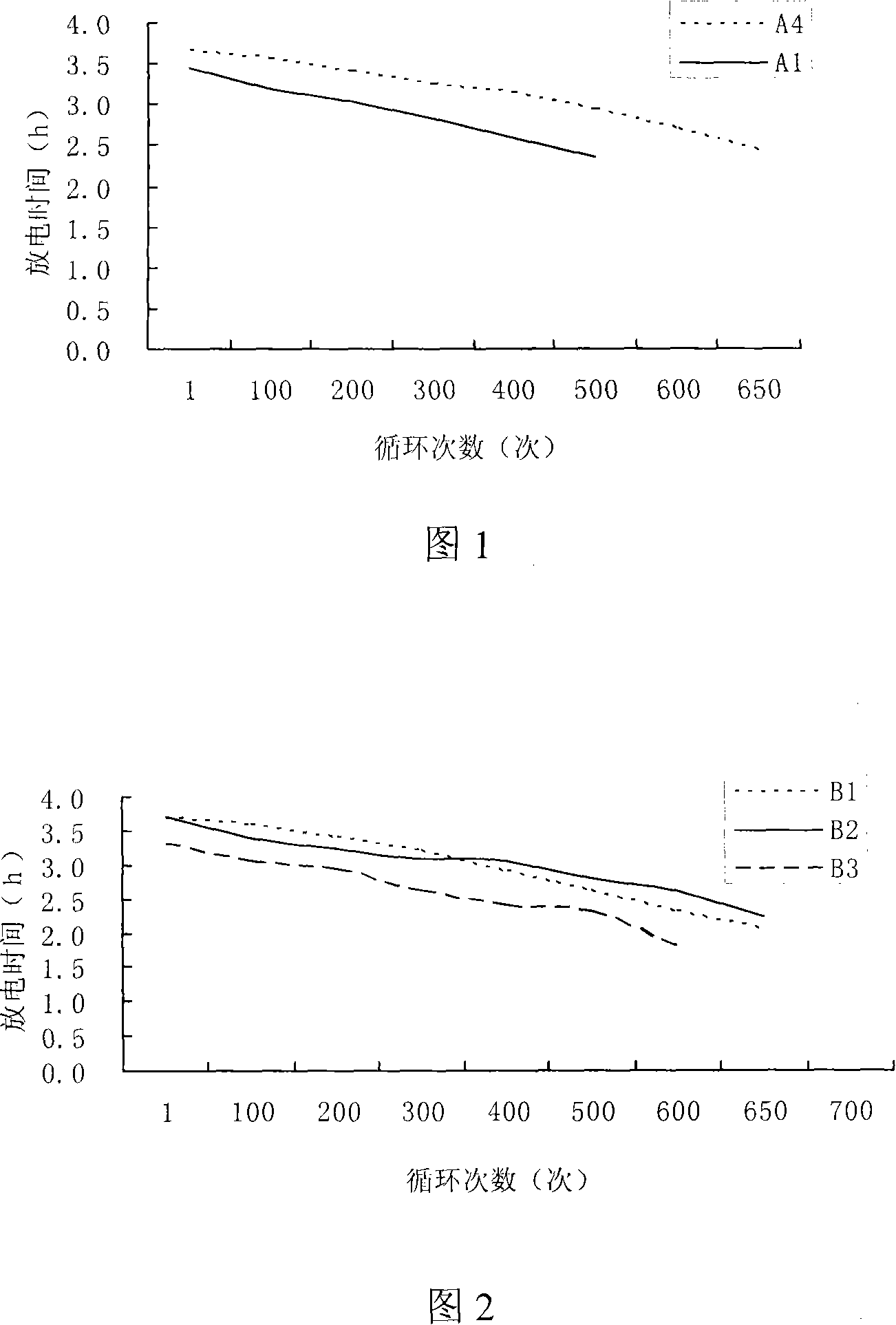

[0013] Taking the conventional 6V4AH battery as the sample battery, two battery structures were used for orthogonal experiments. After the battery is made, test the 20h rate, the initial capacity of 3C, the specific energy by weight, and the cycle life according to the national standard of technical conditions for small valve-regulated sealed lead-acid batteries (GBT 19639.1-2005).

[0014] The battery is assembled with Z1.6A 2 positive and 3 negative structures, and the comparative lead paste formulas A1 to A3 are the three most common positive electrode lead paste formulas in current practical use. The percentages stated in the formulas A1 to A4 are all percentages by weight.

[0015] Formula A1: 100% lead powder, deionized water content is 11% of lead powder, 1.40g / cm 3 The sulfuric acid content is 10.5% of the lead powder, and the short fiber content is 0.05% of the lead powder.

[0016] Formula A2: 100% lead powder, deionized water content is 11.5% of lead powder, 1.40g...

Embodiment 2

[0033] Take each composition by weight percentage as follows:

[0034] 1. Lead powder 100%, 1.40g / cm 3 The sulfuric acid content is 12% of the lead powder, the deionized water content is 11% of the lead powder, the lead dioxide content is 4.2% of the lead powder, the short fiber content is 0.06% of the lead powder, and the carbon fiber content is 0.08% of the lead powder. The anisotropic graphite content is 0.4% of the lead powder, and the bismuth oxide content is 0.11% of the lead powder. Mix lead powder, lead dioxide, anisotropic graphite, short fiber, carbon fiber, and bismuth oxide into the paste mixing machine, stir for 5 minutes, then quickly add deionized water and stir evenly, then slowly add sulfuric acid and stir evenly, and prepare Lead paste is used to make 6V4AH batteries, marked as B1.

[0035] 2. Lead powder is 100%, 1.40g / cm3 sulfuric acid is 11% of lead powder content, deionized water is 10.5% of lead powder content, lead dioxide is 3.9% of lead powder conte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com