Method for preparing nanometer lead dioxide electrode

A technology of lead dioxide and titanium dioxide, which is applied in the field of water treatment technology and electrochemistry, can solve the problems of complex preparation process, weak oxidation performance, low oxygen evolution overpotential, etc., and achieve broadened research space, electrocatalytic activity and service life Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

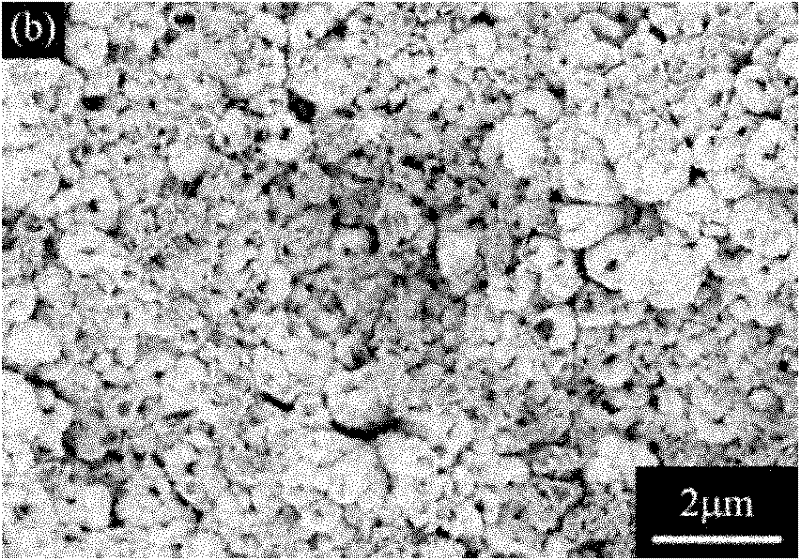

[0060] Preparation of ordinary lead dioxide electrode by electrodeposition on titanium substrate:

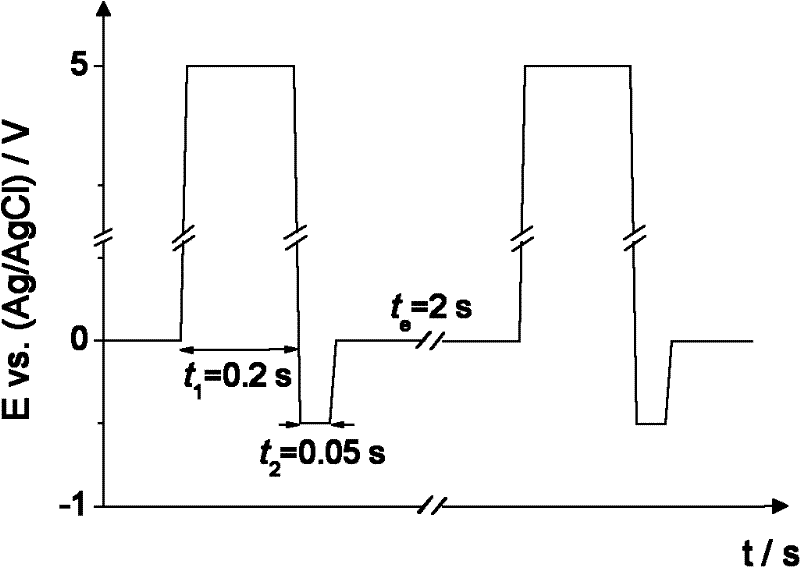

[0061] Cut the titanium plate into 2cm×5cm titanium sheets, and polish it with No. 100, No. 400, and No. 800 sandpaper successively until it is bright and free of scratches. Ultrasonic cleaning with acetone and pure water for 15 minutes respectively, and then microboiling treatment in 10% oxalic acid for 1 hour. After thoroughly washing with distilled water, pulse electrodeposition was carried out in a three-electrode system using it as a working electrode, a lead plate as a cathode, and silver / silver chloride as a reference. The pulse of each cycle is divided into three sections, and the time length of each section and the voltage applied in the time section are respectively t 0 = 2s,E e = 0V; t i =0.2s,E 1 =5.0V; t 2 =0.05s,E 2 =-0.5V.

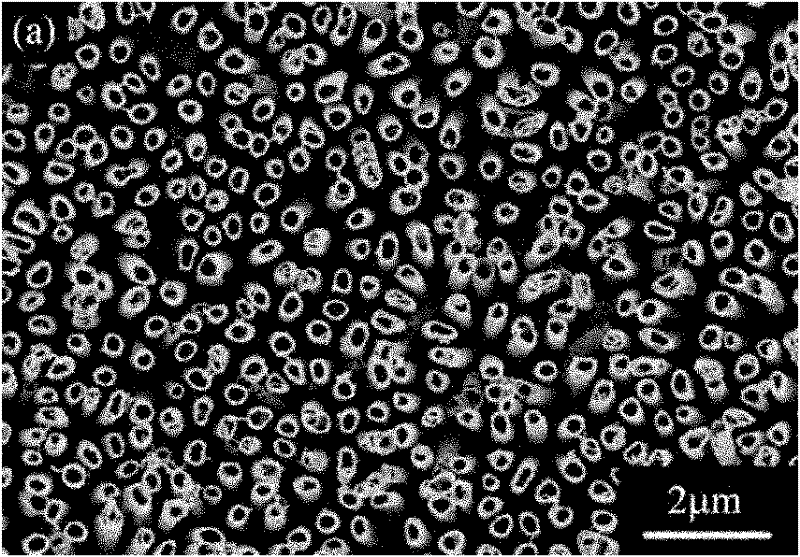

[0062] Preparation of nano-lead dioxide electrodes by electrodeposition on titania nanotube array substrates:

[0063] (1) Preparatio...

Embodiment 2

[0077] The method for preparing a common lead dioxide electrode by electrodeposition on a titanium substrate is the same as that of Example 1.

[0078] Preparation of nano-lead dioxide electrodes by electrodeposition on titania nanotube array substrates:

[0079] (1) Grind the cut titanium sheet (20mm×50mm×1mm) with No. 100, No. 400 and No. 800 sandpaper successively until the surface of the titanium sheet emits a uniform and obvious metallic luster, and the color of the unpolished area will follow that of the polished one. It is not the same, and strive to polish completely. Prepare a degreasing agent with 20g L-1 sodium hydroxide, 35g L-1 sodium carbonate and 5g L-1 sodium silicate, put the polished titanium sheet into the degreasing agent at 90°C for 10 minutes, and wash it with distilled water Then carry out pickling: put it into hydrochloric acid with a volume ratio of 1:1 to water and heat at 80°C for 10 minutes.

[0080] Use 80.3g of diethylene glycol and 2.8g of 40% ...

Embodiment 3

[0092] The preparation method of two kinds of electrodes is identical with embodiment example 2. The difference lies in the used fluorine-containing electrolyte and anodization conditions during the anodization process for preparing the nanometer lead dioxide electrode. The fluorine-containing electrolyte was changed to 0.27M ammonium fluoride solution prepared in glycerol-water solution with a volume ratio of 1:1. Correspondingly, the anodizing conditions were changed: a pretreated titanium sheet was used as an anode, a platinum sheet was used as a cathode, a direct current of 35V was applied, and anodized for 6 hours.

[0093] The wettability test is carried out on a contact angle meter, and the liquid dropped on the surface of the electrode to be tested is distilled water. By comparing the contact angles of water droplets on different electrode surfaces, we found that due to the large difference in the wettability of the two lead dioxide electrode substrates, the contact a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com