Coupling-based non-contact temperature measurement system and coupling-based non-contact temperature measurement method

A temperature measurement, non-contact technology, applied in the field of non-contact temperature measurement systems based on coupling, can solve problems such as installation difficulties, potential safety hazards of power equipment, and inability to measure temperature safely, and achieve the effect of low cost and simple circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to describe the present invention more specifically, the measuring system and its measuring method of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

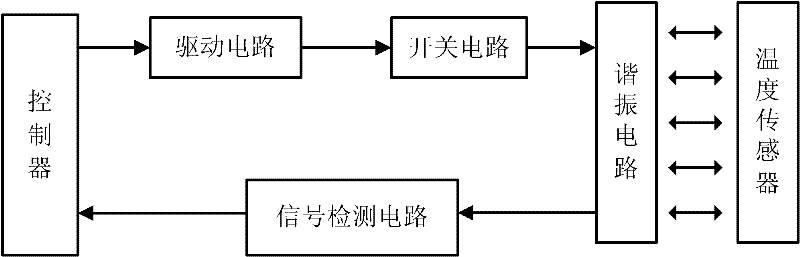

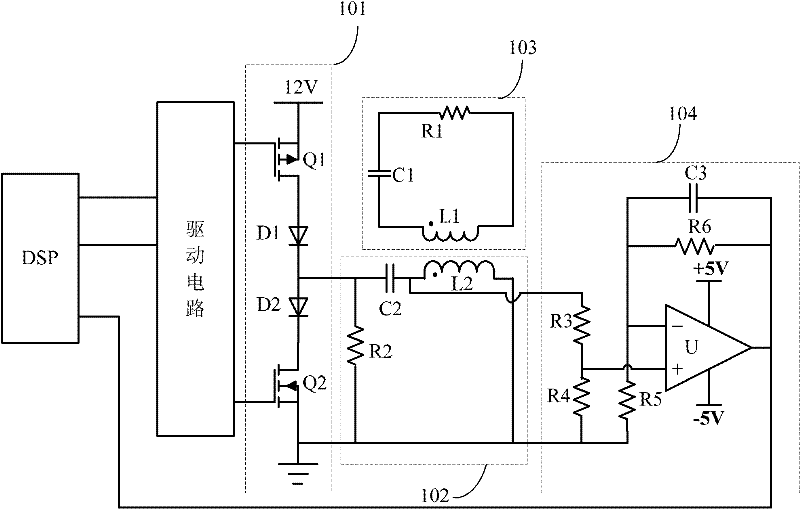

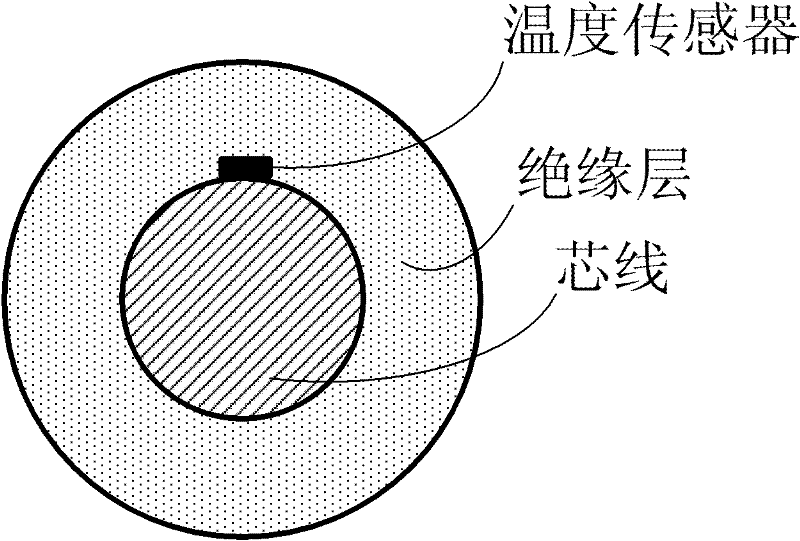

[0041] Such as figure 1 and figure 2 As shown, a coupling-based non-contact temperature measurement system includes: DSP, drive circuit, switch circuit 101 , resonant circuit 102 , signal detection circuit 104 and temperature sensor 103 .

[0042] The driving circuit is connected with the DSP, which amplifies the two driving signals provided by the DSP and then outputs it; in this embodiment, the driving circuit adopts the IRF2110 chip of International Rectifier Company.

[0043] The switch circuit 101 is connected with the drive circuit, and outputs a square wave signal according to the two amplified drive signals provided by the drive circuit; in this embodiment, the switch circuit 101 is composed of two MOS transistors Q1-Q2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com