A two-degree-of-freedom ultrasonic motor and its driving method

A technology of ultrasonic motor and degree of freedom, which is applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc. It can solve the problems affecting the stability of ultrasonic motor and improve the output torque , large contact area, convenient reversing control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

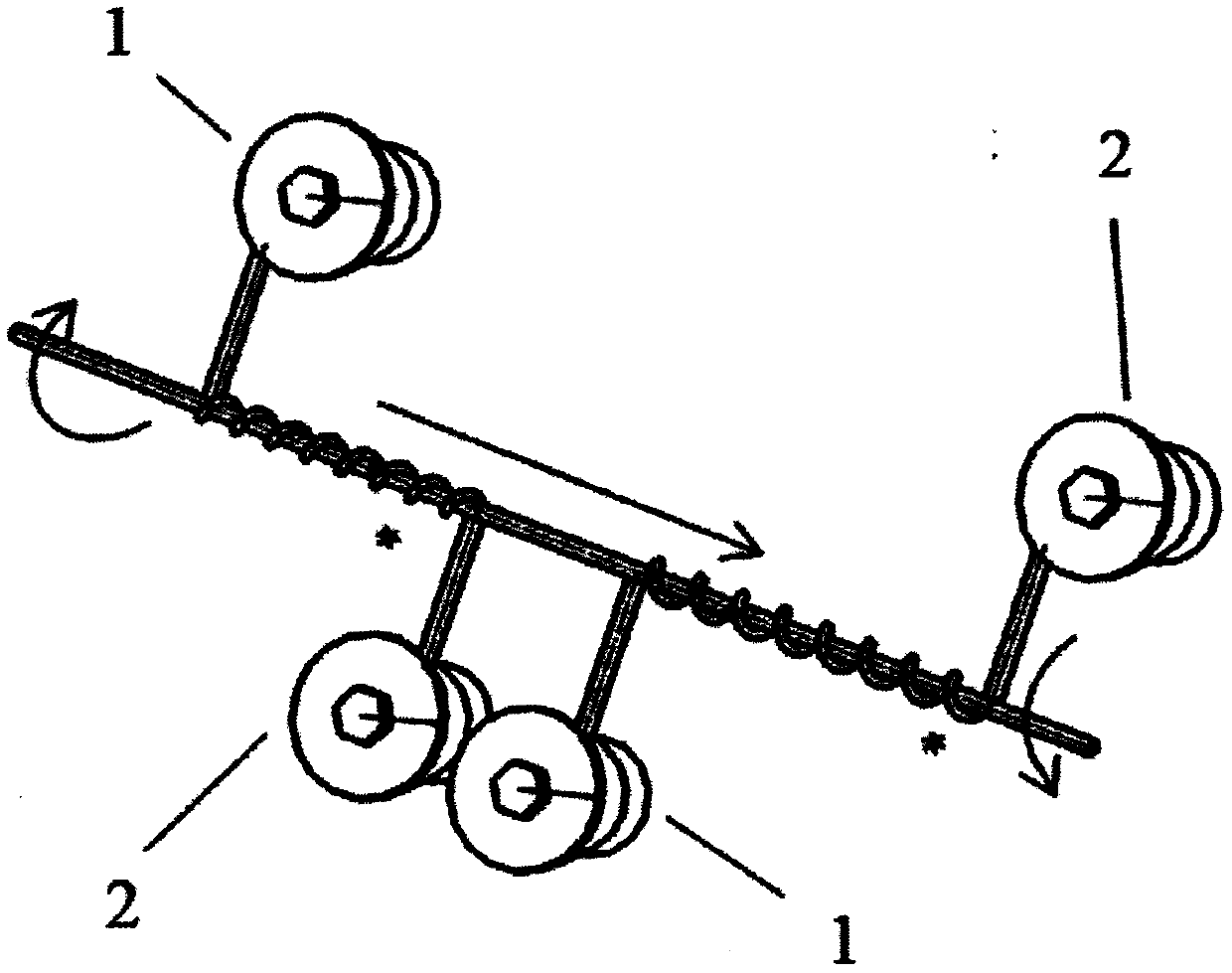

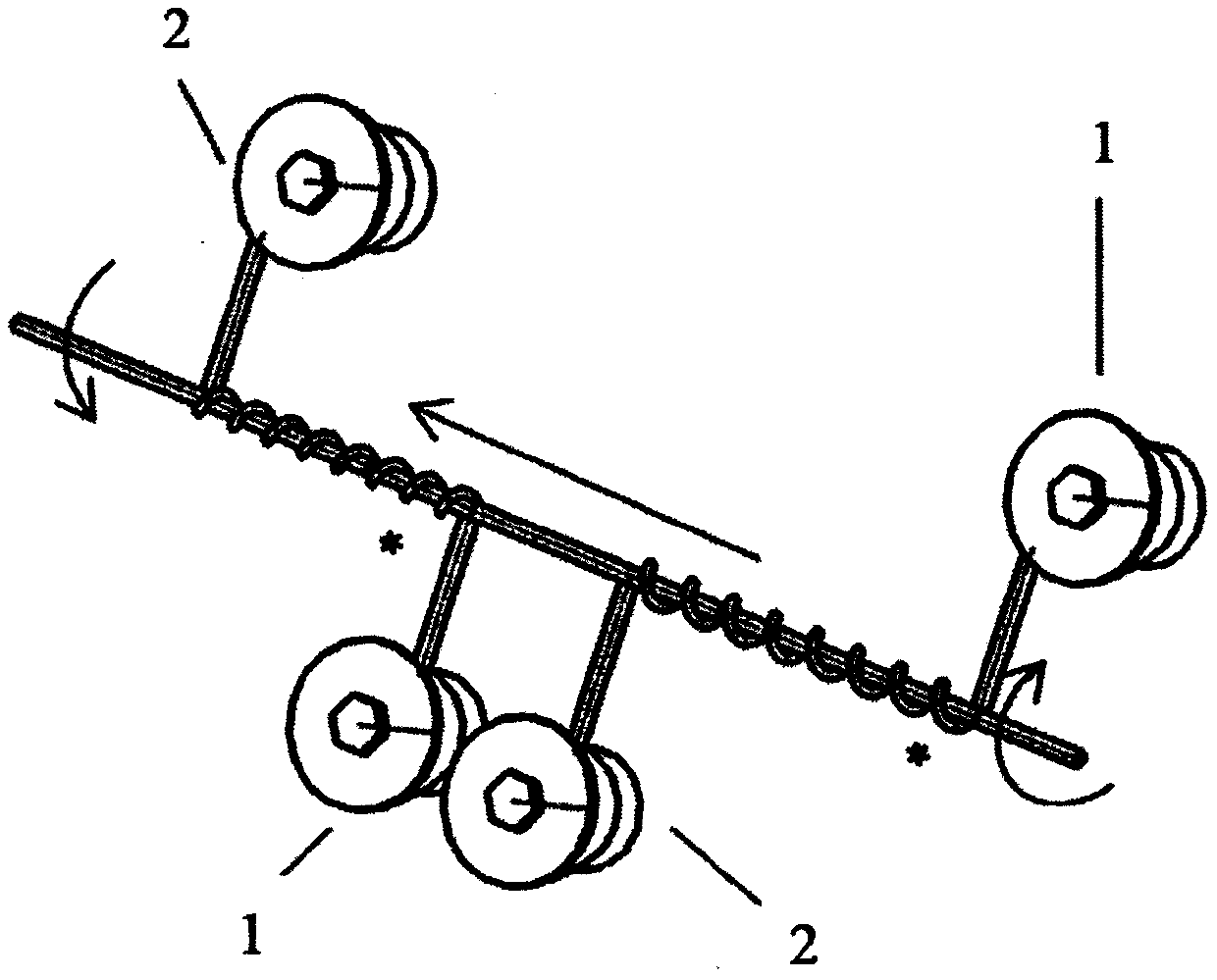

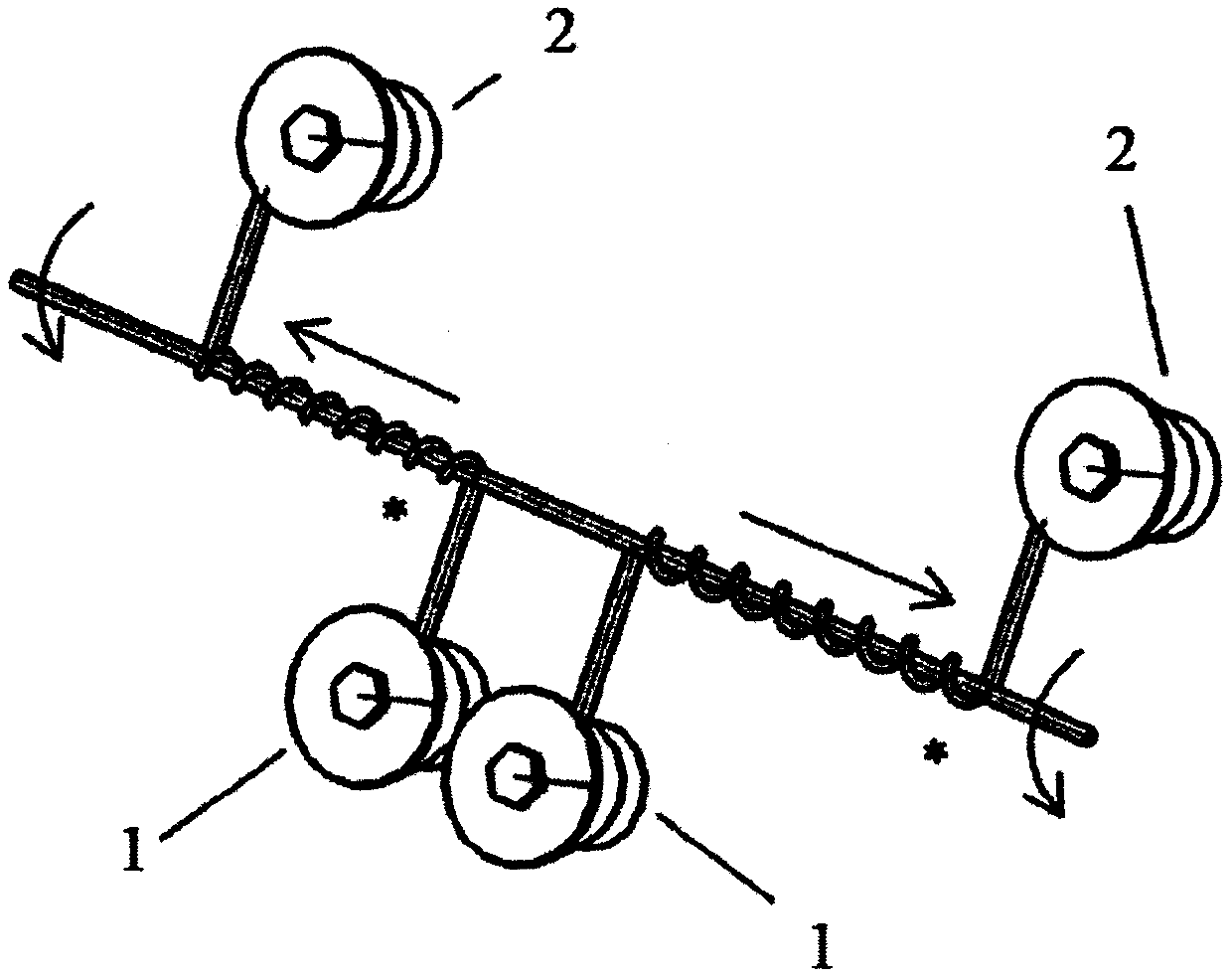

[0024] An ultrasonic motor with linear and two degrees of freedom of rotation: the stator is composed of two helical structures; the rotor is a tubular structure with an outer diameter slightly smaller than the inner diameter of the stator helix; the rotor passes through the interior of the two helixes; two helical stators, one left-handed , a right-handed, symmetrical parameters, coaxial installation; the material of the spiral stator is metal, and the section is rectangular, square or circular.

[0025] The driving method of the two-degree-of-freedom ultrasonic motor is:

[0026] One end of the helical structure stator is connected to the ultrasonic vibrator, and the other end is connected to the vibration absorber or an excitation signal with a certain phase relationship with the vibrator is applied to excite the stator to generate traveling waves along the helix; the two helical stators are driven independently; the two helical The specifications and parameters of the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com