Catalytic cracking fractional and divisional transformation method and device for heavy oil

A technology of catalytic conversion and heavy oil catalysis, applied in the field of petroleum processing, can solve the problems of insufficient reaction depth of inferior raw materials, inferior quality of catalytic cracking raw materials in refineries, retardation and other problems, so as to solve the problem of increasingly inferior quality, avoid vicious adsorption competition, Yield-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

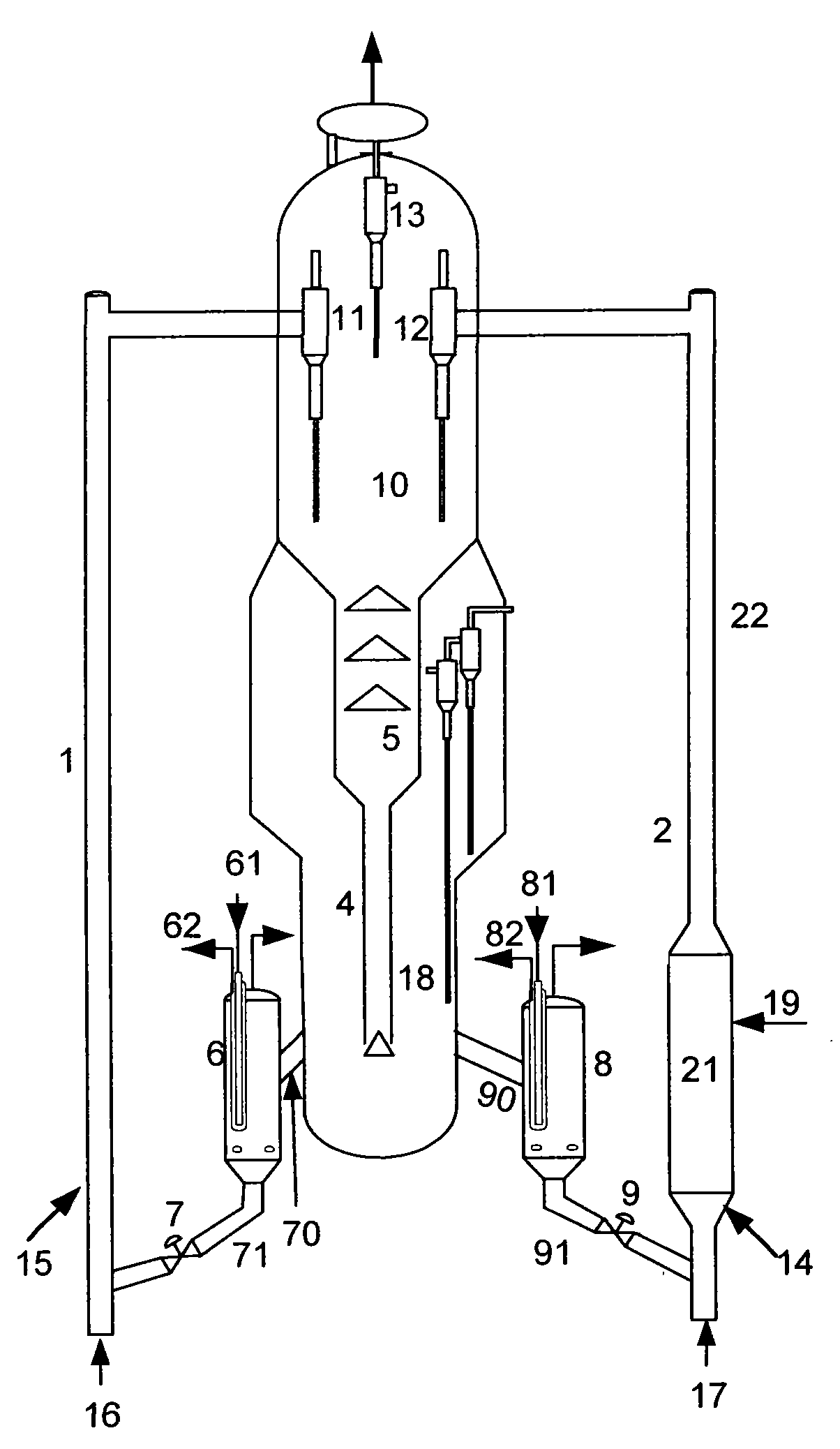

[0047] The present invention provides a method for heavy oil catalytic cracking fractional conversion and a device for implementing the method, please refer to figure 1 As shown, the heavy oil catalytic cracking staged conversion device in this embodiment mainly includes: a riser reactor 1, a combined reactor 2 with a turbulent bed or a fast bed plus a transport bed, an oil-gas separation system, a catalyst regenerator 4, and two Regenerated catalyst coolers 6,8. Wherein, the bottom of the riser reactor 1 is provided with a high-quality catalytic raw material inlet and a catalyst inlet, and the top is provided with a mixed material outlet of the reacted oil gas and catalyst; the combined reactor 2 is a turbulent bed or a fast bed 21 and a transport bed 22 Combined reactors in series, the turbulent bed or fast bed 21 is arranged at the bottom of the combined reactor 2, and the height is 5% to 30% of the overall height of the combined reactor 2, and the turbulent bed or fast bed...

Embodiment 2

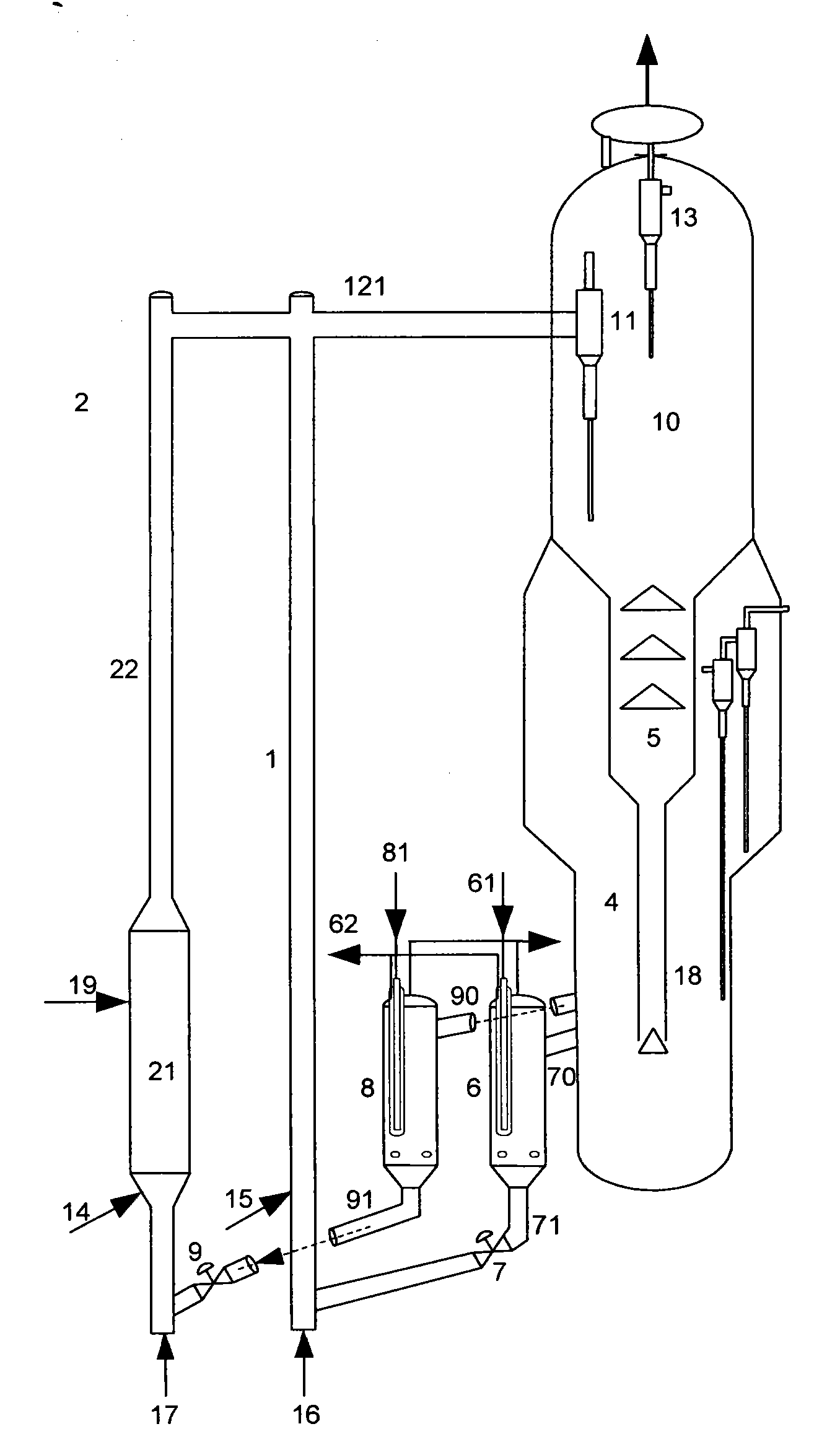

[0051] Please refer to figure 2 As shown, wherein, the conventional riser reactor 1 (the regenerated catalyst cooler 6 is arranged between the regenerator 4 and the riser reactor 1) which is set for high-quality raw materials next to the regenerator 4 of the heavy oil catalytic cracking unit and is set for low-quality raw materials The turbulent bed or fast bed plus transport bed combination reactor 2 (regenerated catalyst cooler 8 is arranged between the regenerator 4 and the combination reactor 2) after the catalyst after the reaction and the oil-gas mixture material outlet converge at 121, the catalyst and After the oil and gas are separated by the oil and gas separator 11, the settler 10 and the top spin 13, the oil and gas are led out of the catalytic cracking reaction system, and the catalyst enters the stripping section 5 for stripping, and then enters the regenerator 4 through the catalyst delivery pipe 18 for charring regeneration. Other structures and processes of t...

Embodiment 3

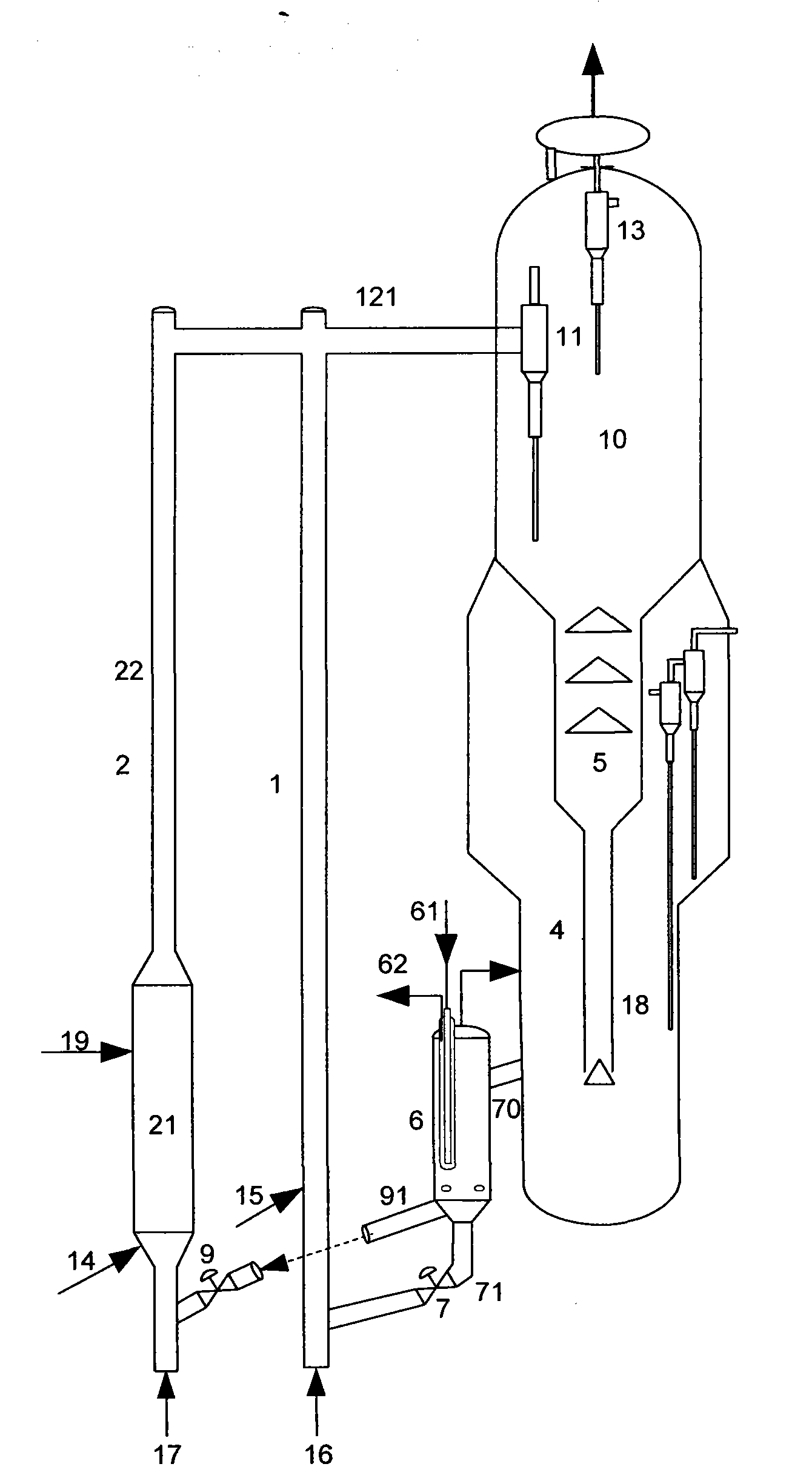

[0053] Please refer to image 3 As shown, among them, the conventional riser reactor 1 set for high-quality raw materials next to the regenerator 4 of the heavy oil catalytic cracking unit and the turbulent bed or fast bed plus transport bed combination reactor 2 set for low-quality raw materials, and in the regenerator 4 A regenerated catalyst cooler 6 is arranged between the riser reactor 1 and the combination reactor 2 . The high-temperature catalyst in the regenerator 4 enters the regenerated agent cooler 6 through the catalyst delivery pipe 70, passes into the cooling medium through 61, and flows out through 62, and reduces a part of the regenerated catalyst with a temperature of 680-710°C to 580-670°C, and then Enter the riser reactor 1 through the regenerated inclined pipe 71 and the regenerated catalyst slide valve 7, and flow upward under the lifting action of the lifting gas 16 to contact and react with high-quality catalytic raw material oil 15 (the carbon residue v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com