Sealed bearing comprehensive performance simulation testing machine

A comprehensive performance and simulation test technology, applied in the direction of mechanical bearing testing, etc., can solve the problems of low load accuracy, inability to simulate humidity and heat, alternating humidity and heat in alternating dry and wet application environments, and inability to simulate rapidly changing load application conditions, etc., to achieve Real performance and life reliability evaluation, high loading accuracy and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0024] Example.

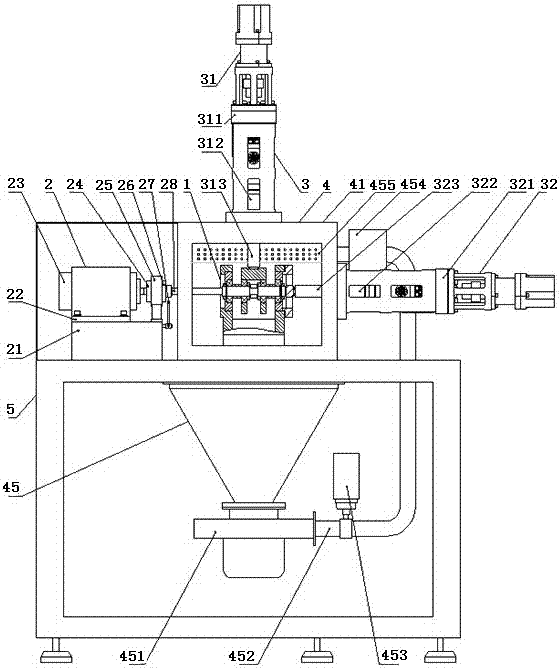

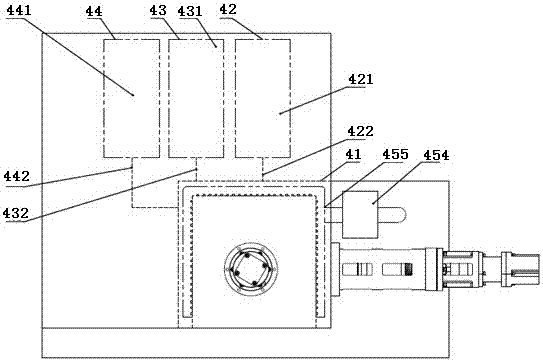

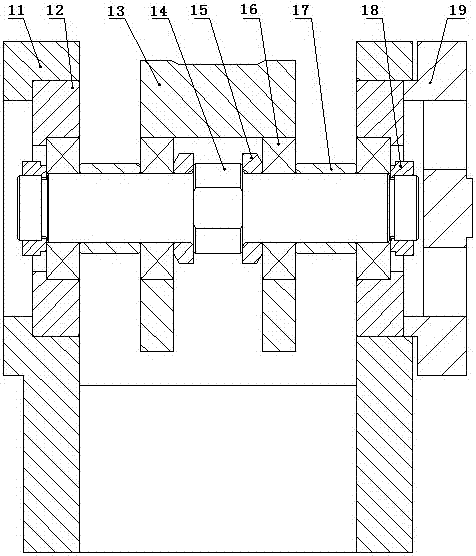

[0025] see Figure 1 to Figure 4 , this embodiment mainly includes five parts: a bearing test unit 1, a drive unit 2, a loading unit 3, an environment simulation system 4 and a control system. The bearing test unit 1 is set in the environmental chamber 41 of the environmental simulation system 4, is set on the same plate as the driving unit 2, and is connected to the loading unit 3; the driving unit 2 is set on the left side of the environmental chamber 41; the loading unit 3 includes radial Two parts, the loading mechanism 31 and the axial loading mechanism 32, the radial loading mechanism 31 is set on the upper side of the environmental box 41, and the axial loading mechanism 32 is set on the rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com