A kind of ternary lithium battery safety classification method

A ternary lithium battery, safe technology, applied in the direction of secondary battery, electrolyte battery manufacturing, non-aqueous electrolyte battery, etc., can solve the problems of battery fire and explosion, safety accidents, battery and storage cabinet equipment fire, etc., to avoid hidden dangers , to avoid fire and explosion, to ensure the consistency of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] In this embodiment, the previous process is converted to 3.7V as an example. The specific steps of capacity division are as follows:

[0034] (1) After the battery is formed and aged, it is transferred to the upper compartment;

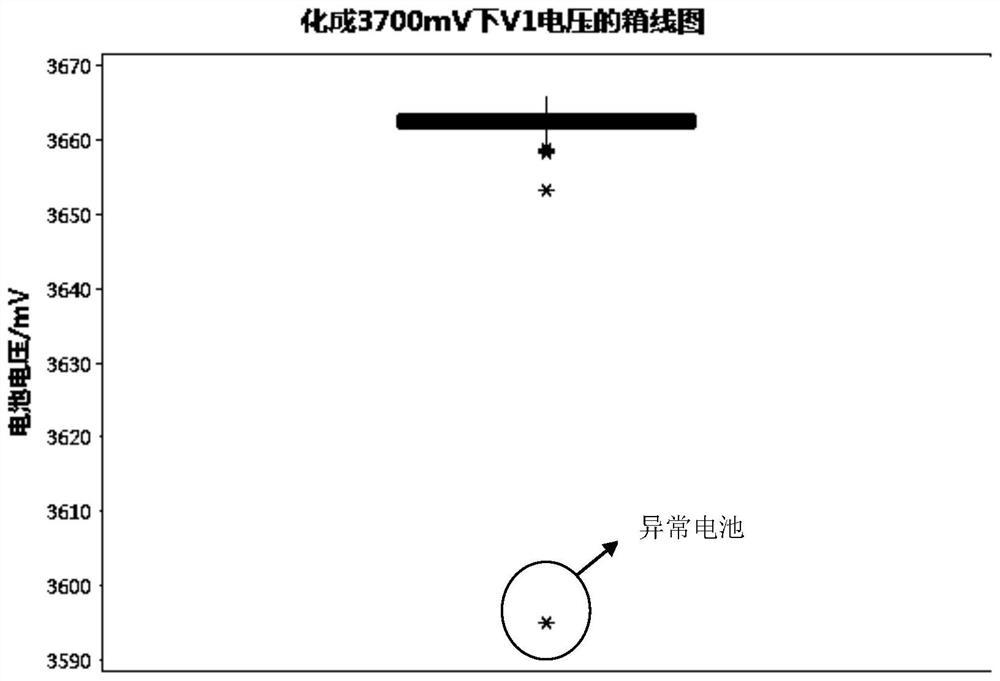

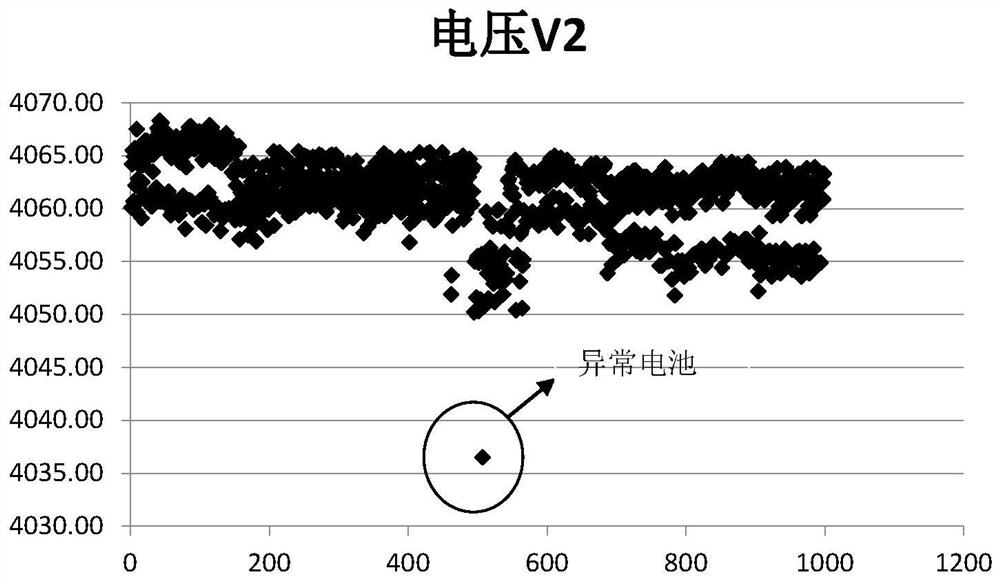

[0035] (2) The sub-container detects the battery voltage, which is recorded as V1;

[0036] (3) Set aside for 2 minutes;

[0037] (4) The battery is charged to 4.1V with a constant current of 0.33C;

[0038] (5) Set aside for 5 minutes;

[0039] (6) The sub-container detects the battery voltage, which is recorded as V2;

[0040] (7) The battery is charged to 4.2V with 0.33C constant current and constant voltage;

[0041] (8) Set aside for 5 minutes;

[0042] (9) The battery is discharged to 3.0V at a constant current of 1C, and the discharge capacity Q1 is recorded;

[0043] (10) Set aside for 5 minutes;

[0044] (11) Repeat steps (4) to (8) once;

[0045] (12) The battery is discharged to 3.0V at a constant current of 1C, and the disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com