Breathable low-emissivity metalized sheets

a technology of metalized sheets and breathable sheets, applied in the field of metalized sheets, can solve the problems of less effective thermal barrier, higher emissivity of oxidized metal layers, and susceptibility to metal layer oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0098] This Example demonstrates that the moisture vapor permeability of moisture permeable nonwoven sheets that have low air permeability is substantially unchanged when the sheet is coated and metalized according to the present invention.

[0099] Roll samples (460 m long by 41 cm wide) of HW1, HW2, CW1, and RF1, listed above in Table I, were coated with various polyacrylate layers and metalized with aluminum in a vacuum coating / metallization machine to form the structures listed in Table II (where Al=aluminum and L1, L2, and L3 are diacrylates selected from TRPGDA, SR606, HDODA20% C18, SR9003, and Zonyl®TM / TRPGDA). In structures containing more than one polyacrylate layer, the composition of the polyacrylate layers were the same in some Examples and different in others. The Al thickness was either 22 or 36 nm and the polymer layer thickness (L1, L2, L3) was 0.5 μm.

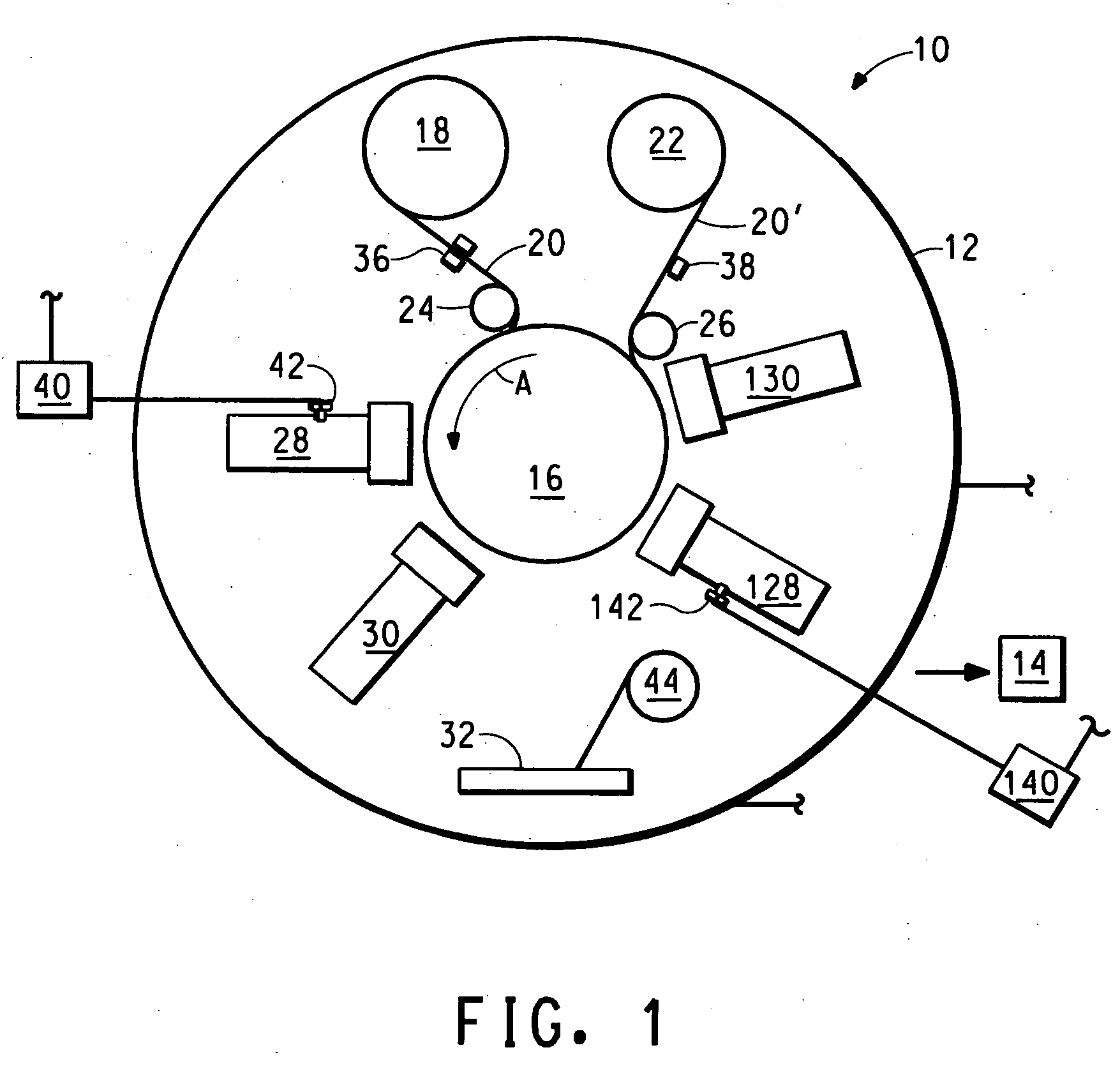

[0100] The vacuum chamber of the vacuum coating / metallization machine included a plasma treatment station, one vapor d...

example 3

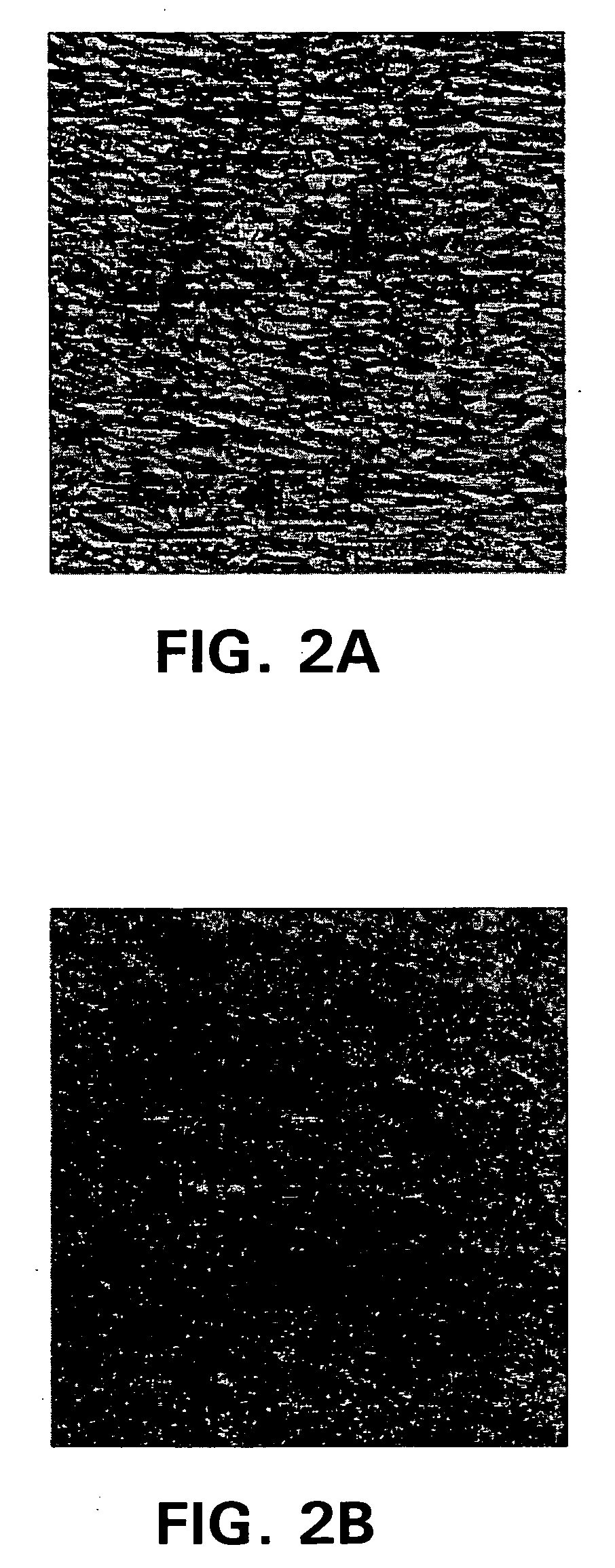

[0109] This example shows the impact of using an intermediate polymer coating (L1) between the sheet layer and the metal layer on the emissivity of metalized sheets prepared according to the present invention.

[0110] Samples of CW1 house wrap measuring 30.5 cm×30.5 cm were coated and / or metalized using separate metalizer and vacuum flash evaporation machines so that, after metallization or polymer deposition, the samples were exposed to air during transfer from one machine to the other. The samples were plasma treated as described in Example 1. Metalized samples were formed having different metal layer thicknesses of 10, 50, and 100 nm using gold or aluminum metal. The thickness of the polyacrylate layer was approximately 0.5 μm. After polymer deposition and / or metallization, the emissivity was measured in multiple locations throughout the sample area. The structures and their properties are shown in Table IV below.

TABLE IVComparison of Emissivity for Metalized Sheets With andWith...

example 4

[0112] This Example demonstrates the impact of an outer polyacrylate coating layer (L2) on emissivity of metalized sheets.

[0113] Coated metalized sheet samples (30.5 cm×30.5 cm) were prepared as described in Example 3. Both samples were prepared during the same coating run with SR606 followed by the same metallization run with aluminum to ensure that the thicknesses of the metal and polymer coating layers were substantially the same for all samples. The structure of the coated samples and emissivities are shown in Table V below.

TABLE VEmissivity of Metalized Sheets With and Without an OutsideLayer of PolyacrylateCoated Sheet StructureEmissivityCW1 / SR606 (0.5 μm) / Al (50 nm)0.18 ± 0.02CW1 / SR606 (0.5 μm) / Al (50 nm) / SR606 (0.5 μm) 0.14 ± 0.0001

[0114] The data in Table V show that samples with L2 have lower emissivity when compared to samples made in the same metallization and coating runs but without L2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com