Automatic spraying machine

A technology of automatic spraying and racking, which is applied in the direction of coating, spraying device, and device for coating liquid on the surface, etc. It can solve the problems of increasing cost, poor spraying effect of complex patterns, and waste of paint, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

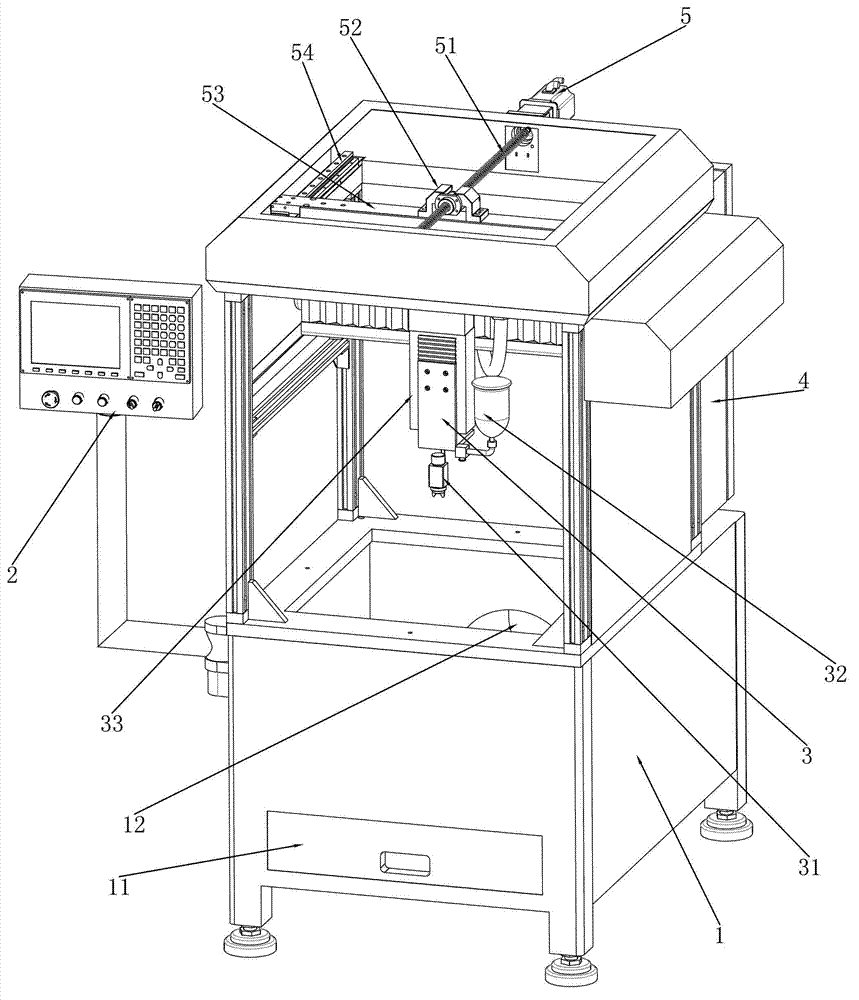

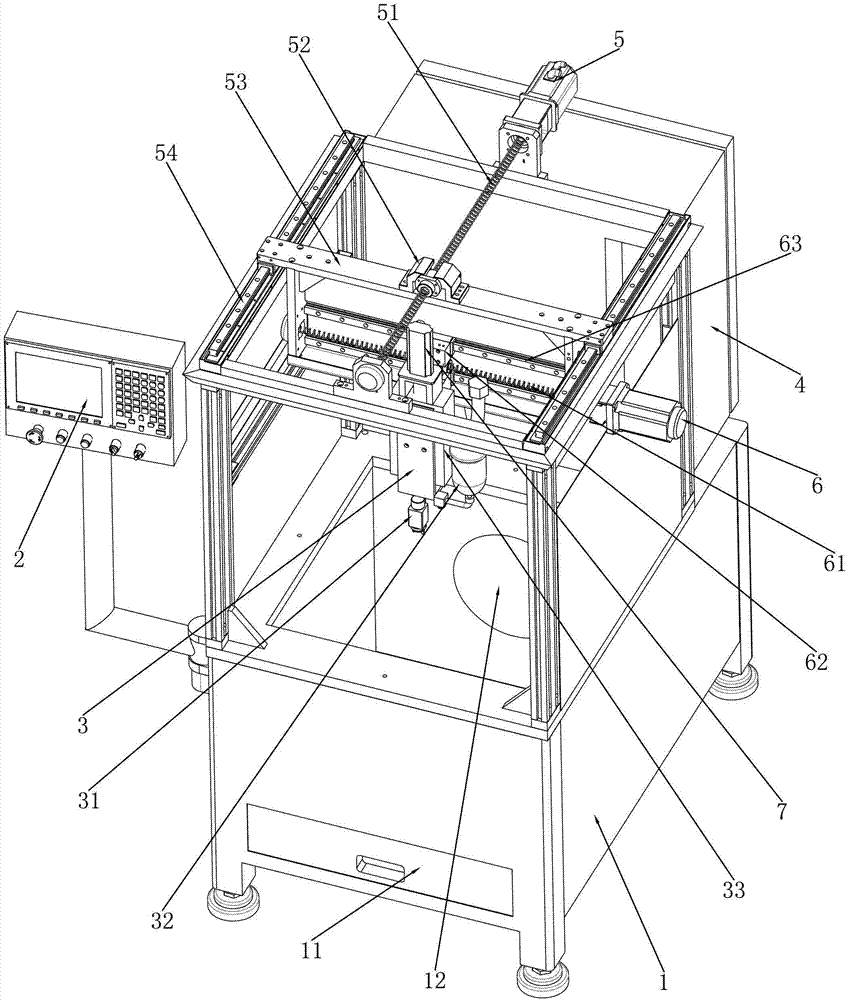

[0019] like figure 1 The shown automatic spraying machine includes a frame 1, and the frame 1 is a cavity shell with a window on the top to pick and place parts, and a shielding window can be set on the window opened, and the shielding window is working It is in the closed state to avoid oil splashing during spraying, and the shielding window is opened when parts need to be taken and placed, and the shielding window can be made of transparent material, so that the spraying situation can be observed at any time during work. There is a recovery tank 11 at the bottom of the frame 1. The recovery tank 11 is mainly used to recover the paint dripped during the spraying process. The recovery tank 11 is designed in the form of a drawer. When the waste in the recovery tank 11 is full, it can be removed from the machine. The bottom side of the frame 1 extracts the recovery tank 11, and then the waste materials are processed in a concentrated manner, which is beneficial to environmental ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com