Method of laser machining of fiber-reinforced composite material and product made by the method

A laser processing method and composite material technology, which is applied in the field of laser processing and processing components of fiber-reinforced composite materials, can solve problems such as slow processing speed, difficult welding/joining processing, loose fiber processing costs, etc., and achieve high joint strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

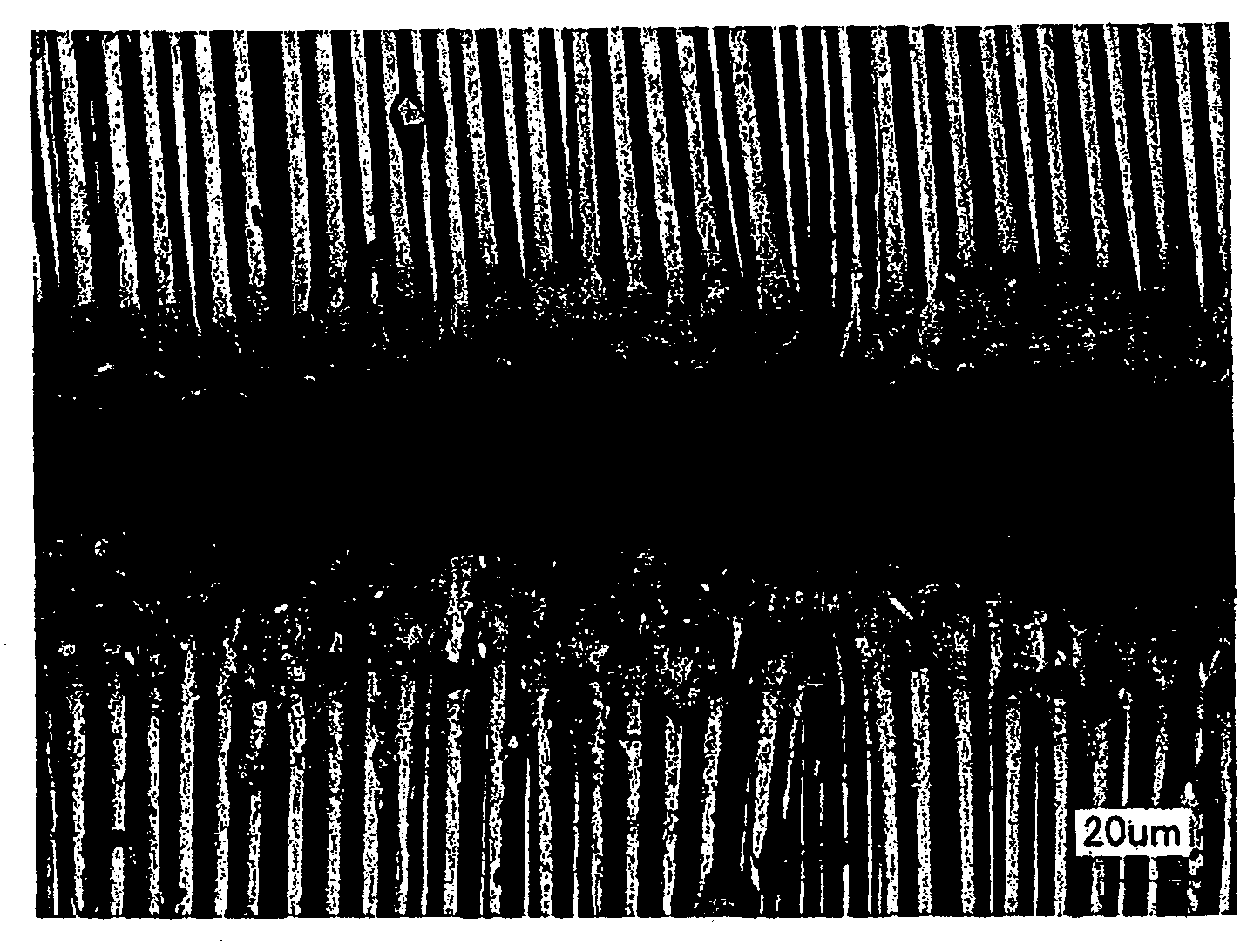

[0040] In the first embodiment, a cutting method using only an ultrashort pulse solid-state laser, a double-sided double laser cutting method, and a single-sided double laser cutting method will be described. Generally, if a composite material 6 such as CFRP is laser cut with a high-power continuous oscillating solid-state laser 1 (such as a fiber laser), it will be as follows: Figure 10 The carbon fibers are shown stripped and their tips melted and carbonized into a ball. If it is cut with an ultrashort pulse laser of 100 picoseconds to 50 nanoseconds (for example, a nanosecond pulse laser of 10 nanoseconds) 3, the laser will act on the electrons in the atomic structure of the object in an instant, heating the surface of the object to Tens of thousands of degrees. Since the time width of the pulse is shorter than the thermal diffusion time of the substance, heat accumulation is generated on the surface, and heat is generated only near the irradiated surface of the material ...

no. 2 example

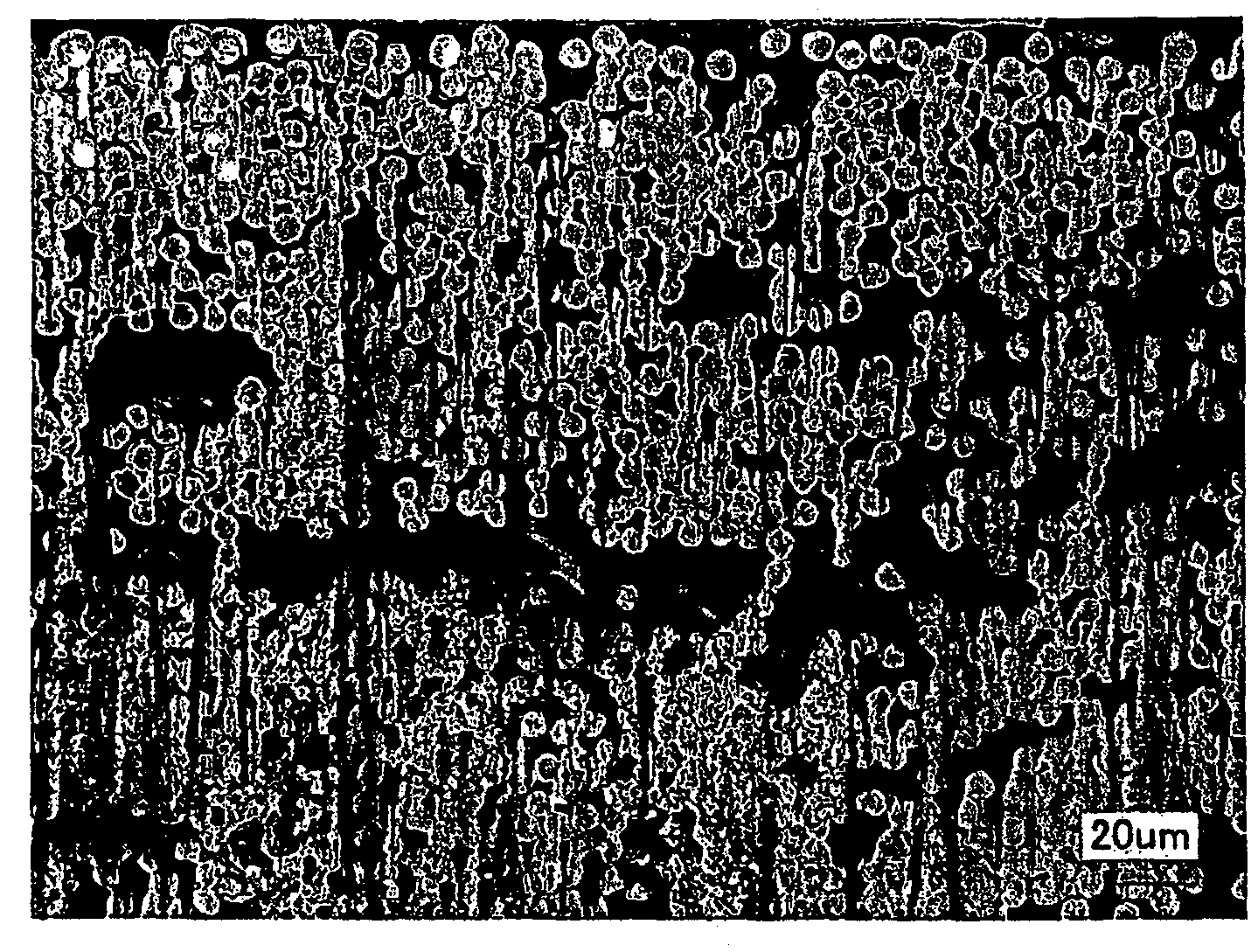

[0044] In the second embodiment, a cascade cutting method using an ultrashort pulse laser will be described. image 3 Shown is a method of cutting a composite material with a thick plate, wherein the laser pass is divided into a fraction of the entire cutting line within the entire cutting line, and the first cascade cutting is performed from the surface 8, the second The second cascade cutting 9, the nth cascade cutting 10, and then the (n+1)th cascade cutting 11, the (n+2) cascade cutting 12, and the (n+3)th Cascade cutting13. This is called the ultrashort pulse laser cascade cutting method in this paper. This is due to the fact that ultrashort pulse lasers remove as little as a few cubic millimeters of material in one pass. But because of this, the quality of its cut surfaces is very high, making it a Figure 11 The cut surface shown.

[0045] For this reason, the pulse repetition frequency of the ultrashort pulse laser is preferably in the range of several kHz to sever...

no. 3 example

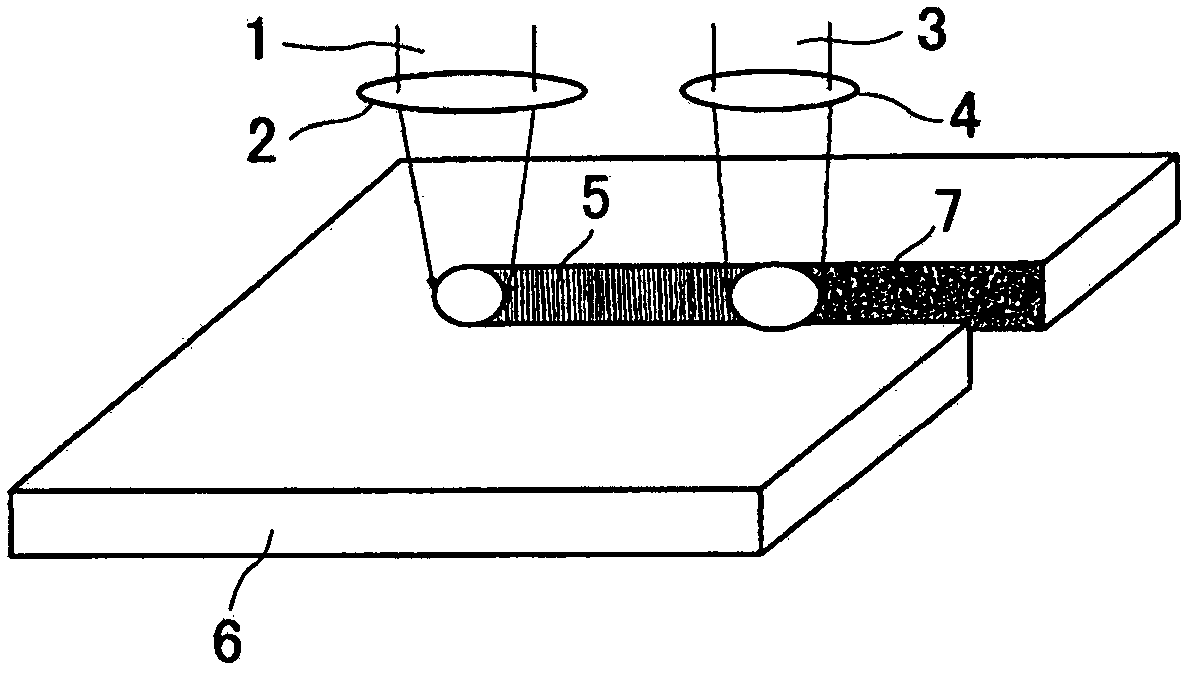

[0047] Figure 4 Indicates an inlay splice. Wherein, 14 is composite material A, 15 is composite material B or metal material, and 16 is the groove surface of welding seam forming. Preferred shapes for weld forming grooves for composite materials or composite laminates include, using the techniques of the first and second embodiments, the shape of the weld forming grooves. , known as a suitable joint for composites or composite laminates.

[0048] Figure 6 A single-layer material and a multi-layer material of an inlaid joint obtained by welding such a joint are shown.

[0049] Among them, 20 is a single-layer material for inlaid and spliced joints, 21 is a multi-layer material for inlaid and spliced joints, 22 is a multi-layer material for inlaid and spliced joints (the first layer), 23 is a multi-layer material for inlaid and spliced joints (the second layer), and 24 is Inlaid joint multilayer material (the third layer), 25 is the inlaid joint multilayer material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com