Tool fixture for cylindrical workpiece punching

A cylindrical and workpiece technology, which is applied to the field of tooling fixtures for drilling cylindrical workpieces, can solve the problems of inconvenient operation and lack of waste collection, and achieve the effects of improving service life and preventing waste from flying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

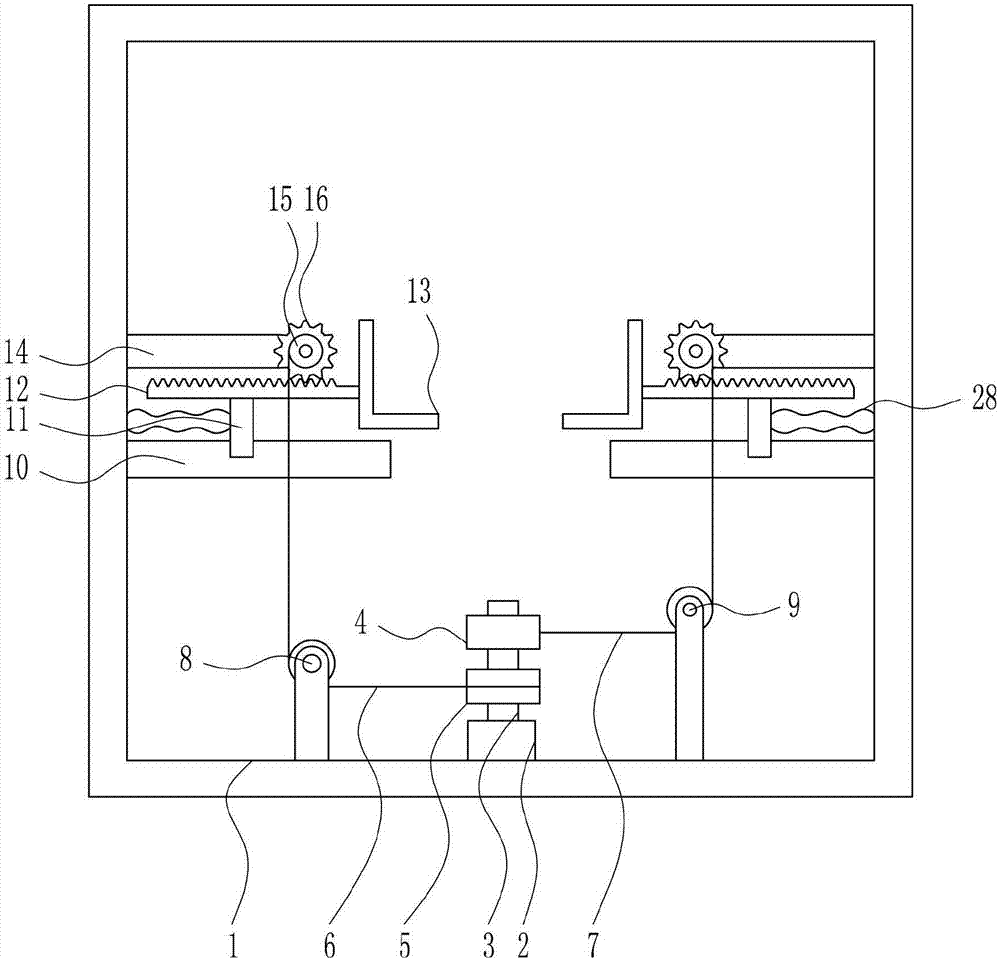

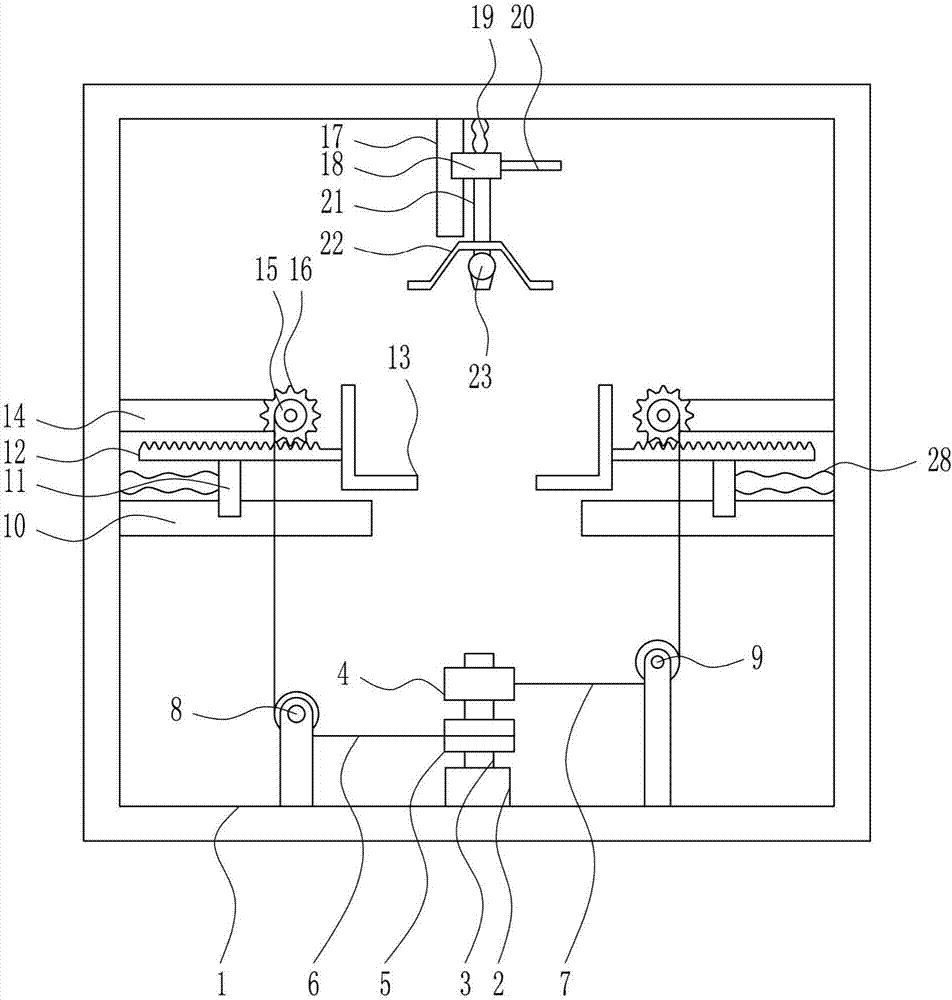

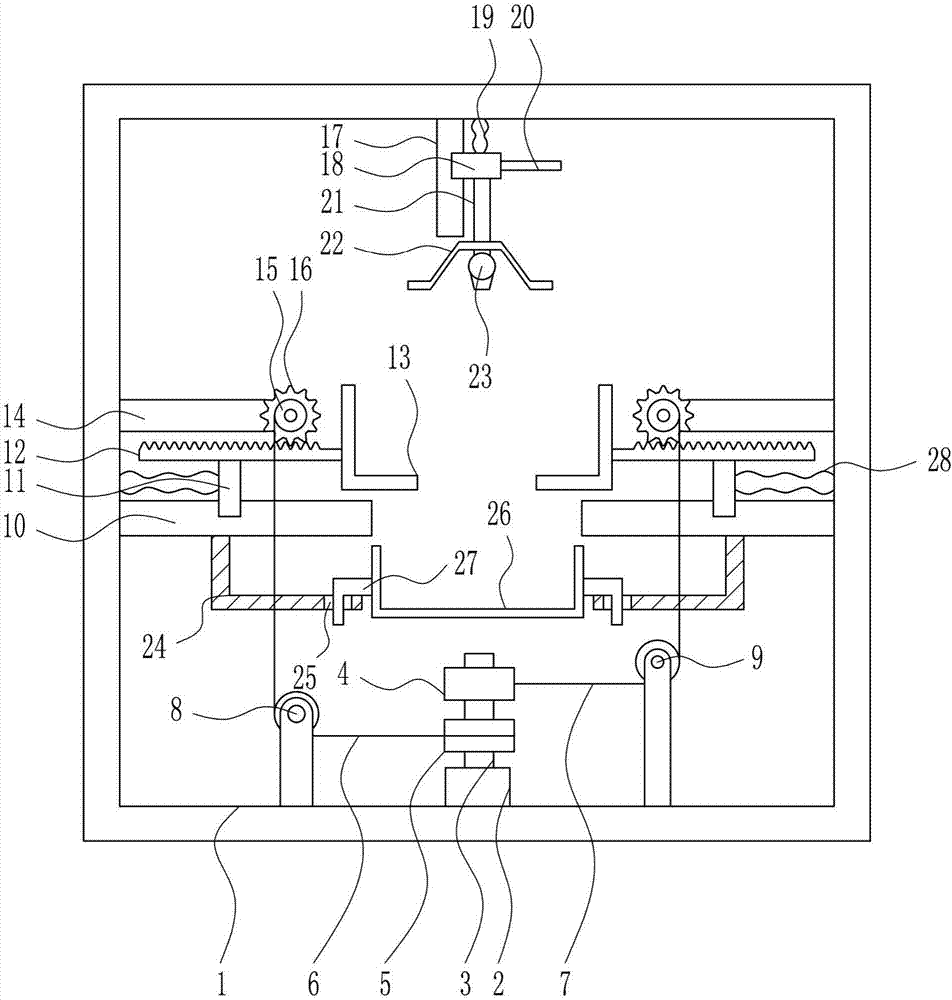

[0027] A kind of frock fixture for punching a cylindrical workpiece, such as Figure 1-3 As shown, it includes a mounting frame 1, a motor 2, a rotating shaft 3, a first winding wheel 4, a second winding wheel 5, a second backguy 6, a first backguy 7, a left fixed pulley 8, a right fixed pulley 9, the first A slide rail 10, the first slider 11, the rack 12, the L-shaped splint 13, the mounting plate 14, the third winding wheel 15, the gear 16 and the second spring 28, and the bottom of the mounting frame 1 is arranged in turn from left to right. Left fixed pulley 8, motor 2 and right fixed pulley 9 are arranged, and motor 2 top is provided with rotating shaft 3, and rotating shaft 3 is provided with first winding wheel 4 and second winding wheel 5, and second winding wheel 5 is on the first Below the reel 4, the bottom of the left and right walls of the installation frame 1 is symmetrically provided with a first slide rail 10, and the top of the first slide rail 10 is slidably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com